Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing

|

By Michigan Tech's Open Sustainability Technology Lab.

Wanted: Students to make a distributed future with solar-powered open-source RepRap 3-D printing and recyclebot recycling. |

|

Contents

Source

- John J. Laureto and Joshua M. Pearce. Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing Technologies 2017, 5(2), 36; doi:10.3390/technologies5020036 open access

- open hardware source code https://osf.io/jvhqt/

- ini file http://www.mdpi.com/2227-7080/5/2/36/s1

- Franklin firmware, Franklin_Firmware_on_GigabotHX:MOST

- Re:3D. Gigabot http://shop.re3d.org/

- OpenSCAD: http://www.openscad.org/

- IC3D Digital Platform. https://www.ic3dprinters.com/index.html

- RAMPS 1.4. http://reprap.org/wiki/RAMPS_1.4

- Pololu A4988 Stepper Motor Drive Carrier. https://www.pololu.com/product/1182

- Arduino Mega Board 2560. https://www.arduino.cc/en/Main/ArduinoBoardMega2560

- KiCad–PcbNew. http://kicad-pcb.org/discover/pcbnew/

- Slic3r. http://slic3r.org/

Abstract

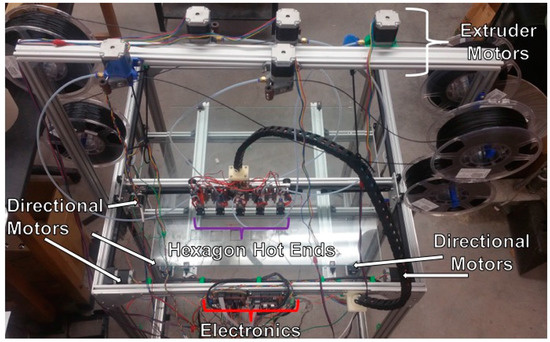

As low-cost desktop 3D printing is now dominated by free and open source self-replicating rapid prototype (RepRap) derivatives, there is an intense interest in extending the scope of potential applications to manufacturing. This study describes a manufacturing technology that enables a constrained set of polymer-metal composite components. This paper provides (1) free and open source hardware and (2) software for printing systems that achieves metal wire embedment into a polymer matrix 3D-printed part via a novel weaving and wrapping method using (3) OpenSCAD and parametric coding for customized g-code commands. Composite parts are evaluated from the technical viability of manufacturing and quality. The results show that utilizing a multi-polymer head system for multi-component manufacturing reduces manufacturing time and reduces the embodied energy of manufacturing. Finally, it is concluded that an open source software and hardware tool chain can provide low-cost industrial manufacturing of complex metal-polymer composite-based products.

Keywords

open source; 3D printing; RepRap; composite; manufacturing; heat exchangers

See Also

- Franklin Firmware on GigabotHX:MOST

- GigabotHX

- Metal wire embedding in fused filament 3-D printing

- Experimental Characterization of Heat Transfer in an Additively Manufactured Polymer Heat Exchanger

- Expanded microchannel heat exchanger

- Towards Low-Cost Microchannel Heat Exchangers: Vehicle Heat Recovery Ventilator Prototype

- Design Optimization of Polymer Heat Exchanger for Automated Household-Scale Solar Water Pasteurizer