MetalicaRap

Release status: Experimental

| Description | An Electron beam melting 3D metal powder printer with scanning electron microscope vision (SEM) & EBM/vaporizing Z axis correction in a vacuum.(Design stage).

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

MetalicaRap .Open Design . Contact. click here [2] Rapatan

Essential PreRead; .. Self Replication Engineering Options See section 2. [3]...Factory at home,See [4]

Hi

We are now 4 months in to the development of a printer capable of printing in all common metals, which can largely print itself. Critically it may offer the ability to largely print the most expensive bits including the electron gun ( Equivalent to printing a 600W fiber laser in a Selective Laser Sintering machine).

This gun will point in to a vacuum chamber above a build platform covered in metal powder.

For now the self replication will not include the vacuum chamber as it will be welded from stainless steel plate, the power supply is under construction from bought in parts and the pumps will initially be purchased.

If you would like to help out with general research ; for example currently we need help with;

- Could you help us get hold of copy of a dos program called EGN2 so we can check our design? Can you ask around? (For details see here:[5]need have contacted authur but unfortunately SLAC can't get hold of a copy)( Aim to get relationship between; spot size µ Vs cathode voltage 60KV to150KV at min vaporizing beam current eg 1mA,),

- Researching the sourcing of components suppliers for our mechanical or high voltage challenges?

- Use your network to help us find more technical specialists, the technical specialists we currently have are very busy people already and needed in electron gun design area.

- Follow the links on our website and try out our design questions !

- Help us research the scanning electron microscope signal processing and image processing.

- Self study the material science to help us with its development free at [http://www.matter.org.uk/universities.htm

]'

None of the processes in them selves are new , they have all been done in other contexts, what is new is that it may offer finished parts requiring no further machining, verification of parts tolerance and bring error correction to metal powder 3D printing for the first time, thus enabling full strength finished dimensional parts production.

For those space buffs, NASA is also making their own machine but with wire not powder, to use EBM's excellent metal grain control ability to achieve "aeroelastic and acoustic tailoring into aircraft structures" For details see here [6]

kind regards

MetalicaRap team

Philosophy

"Since Jones and Swainson many other techniques for rapid prototyping have been developed. Three of the most significant are selective laser sintering (SLS), filament deposition modeling (FDM), and the MIT powder/ink-jet-glue process.A rapid prototyping machine that can make most of its own component parts will clearly be easier to design if one avoids things like high-powered lasers; having the machine make a laser from scratch would be difficult. More subtly, ink-jet print heads (though cheap) are intrinsically hard to make as they involve micro-fabrication, and so a machine based on them would be unlikely (in the medium term) to be able to liberate itself from that one bought-in part. " [7] Adrian Bowyer

As you can see from the above quote even though SLS was one of the 3 major contenders for the reprap machine, it was rejected due to the difficulty of self manufacturing the beam source ie laser, Yet an alternative beam source exists the electron beam (EBM), that may offer self manufacture, due to it largely consisting of 3 simple elements; a cathode metal ring, an anode metal tube and a hot tungsten wire. Another key issue is producing verifiable dimensionally finished parts, commercial metal powder printers can not measure the individual parts they produce, unlike conventional machining methods, MetalicaRap can due to the inclusion of a layer by layer measuring system ( scanning electron microscope SEM).

To manufacture metal parts that can directly "fit" to produce working mechanics is another advantage, in EBM the X and Y axis accuracy is dependent on electrical control rather than mechanical sturdiness giving rise to a inherently stable self reproducibility, On the other hand the challenges of Z axis powder management brings the need for a vision system (SEM) and z axis correction method EBM/vaporization (which is currently in development stage /state of the art on commercial machines.)

Advantages

fully functional parts directly from standard metals

For most parts it may offer dimensionally finished metal parts IT grade 7

Good metallurgy on all common metals, ( Melting process rather than sintering process ensures near 100% of solid material)

Self measurement of part tolerances

May offer automatic self correction.

Disadvantages

Vacuum chamber needs on going maintenance.

Quantity and quality of metal/materials used in vacuum chamber construction, Limited outgasing required [8]

Difficultly in managing metal powders, including issues of; flatness of layers, metal powder trapped in work piece( e.g. designed internal closed cavities, designed internal porous structures,) indicated by the need to have layer error correction.

Quality Control - surface quality/polishing methodology , on the fly heat treatment process development (to overcome residual stress left in work piece).

Chamber approx 1m cube rather than desktop size

Main elements

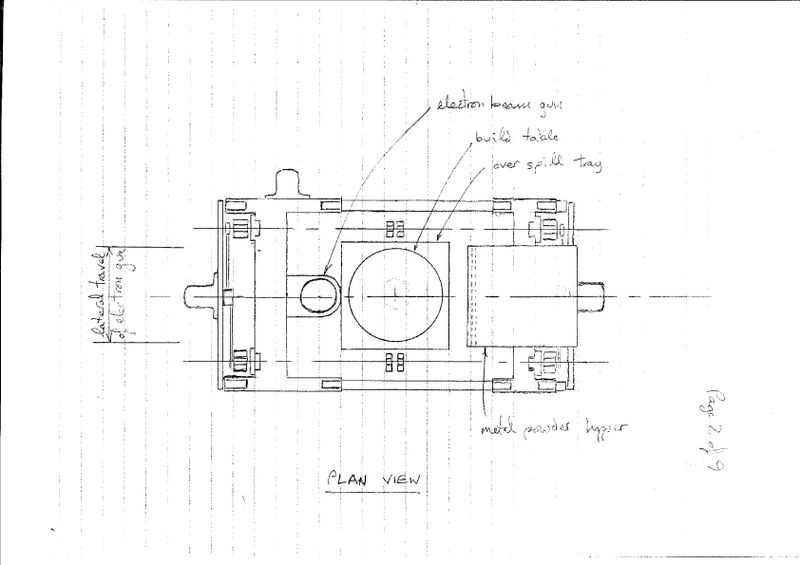

Beyond power supplies, computing power and sensors, MetalicaRap has 5 elements; electron gun, high Vacuum chamber, roughing pump, oil diffusion pump or turbo pump and metal powder dispenser/build platform

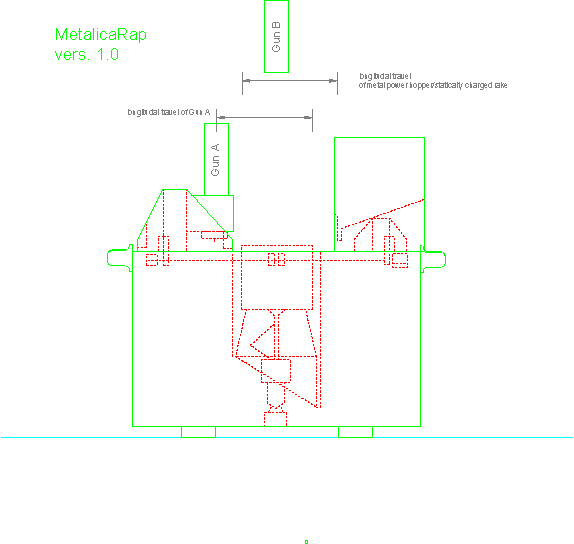

Restricting the design to known technology, 2 guns are required one close to the target and one far from target 1 m away(having functions SEM / Micro vaporizing and melting across build area respectively), Later a second design step might be to combine these functions in one gun again.

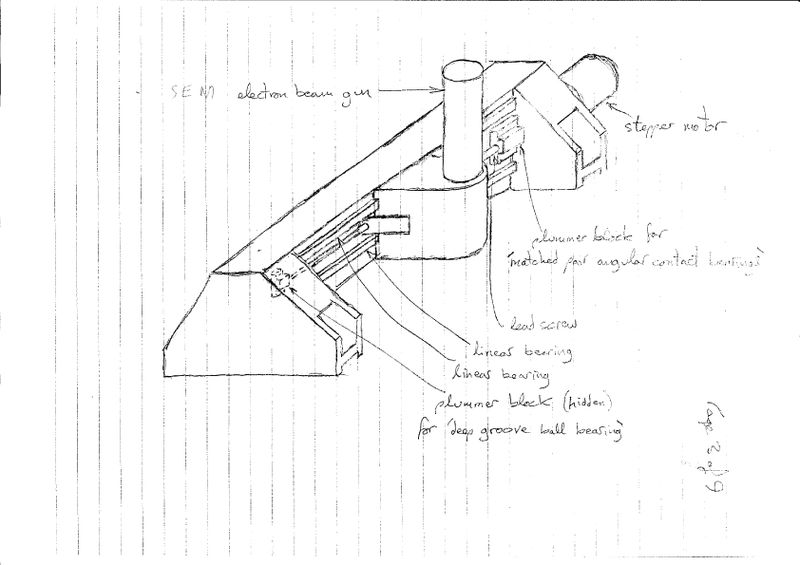

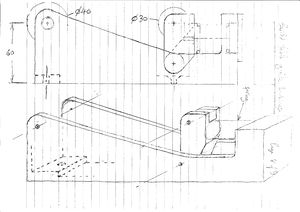

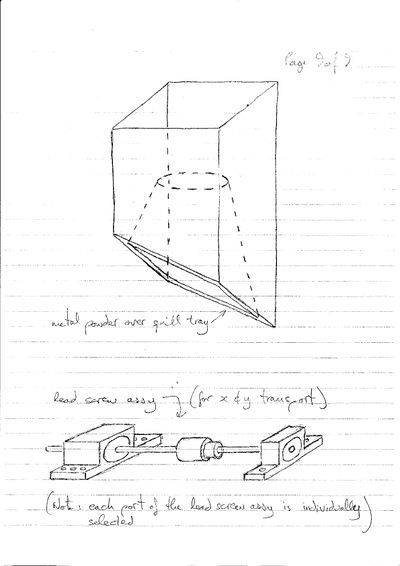

Cartesian Electron Gun A 600W (60KV 10mA) close to build platform on Cartesian X,Y support. Providing subtractive micro vaporizing and vision system

Providing Sub µm Topological mode scanning electron microscope vision system ( See Topographic SEM solution for metalicarap [9])

Additionally providing Micro vaporization (See gun layout Page 3 [10] down to 10µ to 40µ spot size), Initially this would be used to flatten every tenth layer of the build through high points / blobs removal. Future software development could provide live modeling of build, so through the adjustment of beam melting path in following layers errors/ blobs could be taken account of as they arise, thereby limiting the need for blob removal to critical surfaces.

Static Electron Gun B 5KW (150KV 33mA) 1 m above build platform. Providing additive printing through melting at high beam deflection speeds, enabling high build rates

Providing build platform metal powder heating and melting, spot size 100µ ( may be inaccurate) pointing accuracy 10µ ( may be inaccurate). This higher power gun probably will result in the inclusion of a liquid cooling cathode housing system, thou for simplicity it is best avoided.

Nickel, stainless steel and molybdenum are best materials for electron guns as others like brass contain zinc which out-gasses intensely when it gets hot, which can lead to ionization and flash overs. Ceramic or glass are good for insulating elements.

High vacuum chamber (initially welded)

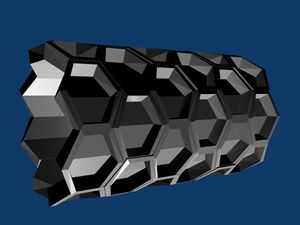

Stainless steel High vacuum 10-5 Tor / (mm mercury) NiCr Alloy (10-16) Hexagonalx40 halfhexagonalx16 endpiecesx16 384 bolts copper wire, future ; airlock so print while repump, main door Viton O ring (Euro ).

Vane pump ( initially purchased)

Oil diffusion pump or turbo pump ( initially purchase Turbo pump )

using existing EBS build design[11] or Turbo pump initially purchased .

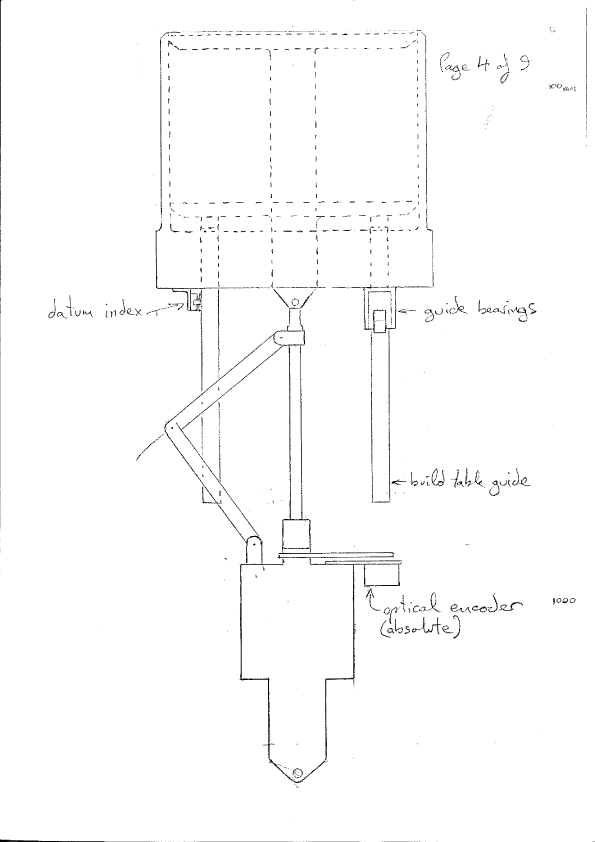

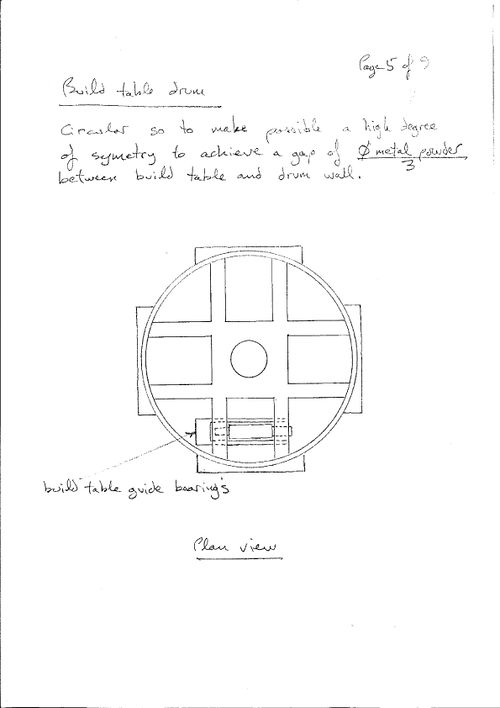

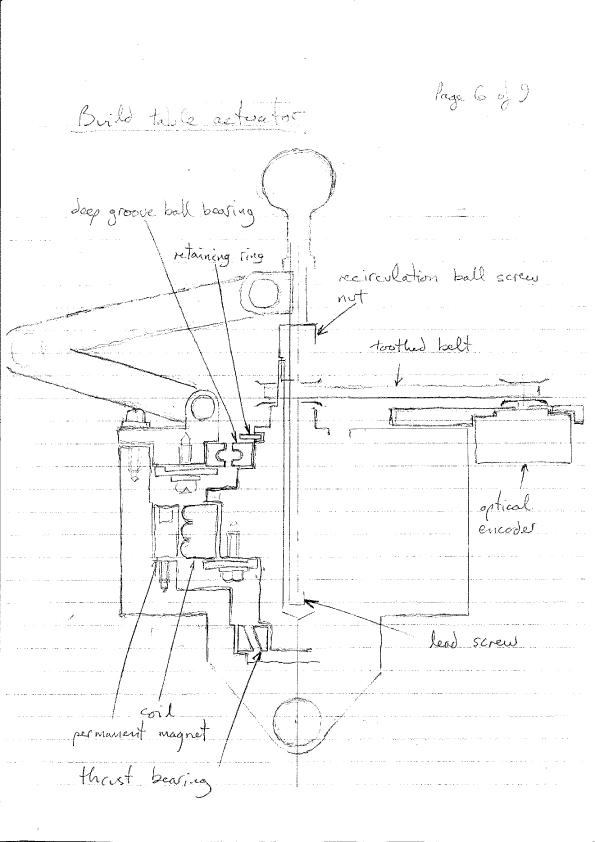

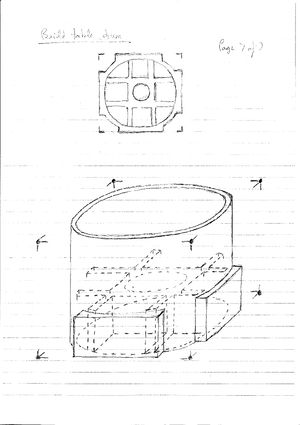

metal powder dispenser / build platform

options include ; screw/ trough design; Wiper deposit ; Metal Vapor protection Gun protection disc SEM pickup,& wiper protection

Power Supply with Arc sense arc quench arc count.

Cartesian 600W gun circuit construction will be based around 2 MOT serialized 5Kv(1Kw) and 6 stage crofton walton ladder for the positive 30Kv side and the same for a negative 30Kv side

Back ground Information on Electron beam processes; electron beam welding / vaporization EBM(1), EBM 3D printing(2),

Scanning electron microscope SEM background(3)(4).

Essential External links follow these first

1. http://www.twi.co.uk/content/spasaug2006.html

2. http://www.arcam.com/technology/ebm-process.aspx

More technical sites

3. http://www.matter.org.uk/tem/sitemap.htm , 4. http://www.uga.edu/caur/semindex.htm

EBM technical background lecture See here [12]

General background Videos EBW see here [13]

Design criteria ; Design a Metal 3D Printer ,Build volume 30cm x 30cm x30cm, that produces dimensionally finished parts +- 20 µ m over 20mm, metallurgy equivalent to wrought iron milled metal parts, largely self reproducing, electrical supply limited to single phase ( ie not 3 Phase,), minimum consumables beyond metal powder ( avoiding need for e.g.argon gas ... etc,),cost for parts less than a small car, build-rate can be slow i.e. .2KG per hour, no bigger than a wardrobe.

Due to lack of control in metal powder deposition & molten metal forming droplet/distortions in conventional ebeam 3D printing (e.g arcam 3d) a tolerance of 300µ in the Z axis is a typical with 10µ powder,( Lower power sizes are prone to magnetic forces and typically unwieldy, though powder demagnetization and non ferrous construction is a possibility, This demands an error correction which is based round a Vision system using 4-sector, independent channel axial Back Scatter electron detectors (BSE) Scanning Electron Microscope (SEM) combined with image processing, the pseudo stereo SEM picture data can be converted to true 3D dimensional data (asymmetrical 4-source BSE photometric stereo 3D-imaging), Enabling sub µ metal height measurement. Z axis dimensional mistakes in any particular layer can be found and corrected by removal of high points through Electron beam machining / ebeam vaporization of the metal. This brings the XYZ axis to 20µ error over 20mm (IT grade 7 See IT grade table[14] 1.). Future stage in development might include Ion beam etching gun to take dimensions to sub µ level(1µ over 20mmIT grade 0). external links 1.http://www.engineersedge.com/international_tol.htm

Research Corner Welcomes Your Contribution

If these knowledge areas are new to you, remember to use your networking skills to talk to others that friend or uncle may be just that expert!

Design Questions;

A. Find magnetic optics simulation packages and run simulations for a Pierce Electron gun running between 500W to 6KW 80KV ? ( given cathode is 1.6m from target max deflection 8 degrees ) ( spot size vs Cathode voltage, ideal guns , for max 60 KV and max 100 KV guns)

B. Possible pit falls of running an SEM at 100W in four-source photometric stereo Ruderford back scatter mode ?

(Depth of field of measurements layer errors over 200µ height, typical SEM power is 0.1W. )

C. Target metal surface temperature measurement would be a big advantage, Do you know of a electron bombardment based remote temperature measurement approach?.

D. Quantify relationship between cathode surface tolerances and electron gun performance, (spot size variation , 2nd order effects etc ) Quantify range of gun performance at cathode tolerances of IT 7.

Design question feed back / discussion. Add your ideas here!

For tracking the process we need help with the following Computer Simulation model's ;

Thermal Real Time Model; this allows us to keep track of the thermal changes across the build chamber or cooling path as the electron gun pulses strike the build volume powder ( energy input). Considering the following 4 situations conduction rates ; 1. Metal powder & solid metal volumes experiencing direct electron energy deposition (i.e. heat around electron penetrated regions, the depth of these volumes increases with Cathode Gun Voltage KV & vary with metal type ) see electron penetration model [15], 2. solid metal thermal conduction volumes ( the completed elements of final metal part under construction) , 3. metal powder conduction volumes ( the surrounding powder) , 4. chamber/boundary thermal conditions ( vacuum region, build box). See electron strike model for different metals and different cathode Voltages.

In general for any unit volume receiving an amount of energy per second to be raised by 1 degree K (the metals specific heat capacity) from a distant energy source, the amount of energy (W or J/s) arriving from that energy source(the electron beam) via a path; The paths energy transit rate (the conduction rate ) is dependent on the cross sectional area of path, the length of path and the temperature difference between the ends of the path, (this is called the thermal conductivity). The volume changes size by the surrounding pressure ( atmospheric pressure, indicating the density of the material).

So from known initial temperature conditions combining the specific heat capacity, thermal conductivity and density to calculate paths, then summing these paths leads to knowing the temperature of a specific unit piece of metal and its physical state, solid or liquid or vaporized (temperature above or below its melting point or vaporization point at any particular time). The following should be considered ; variation of mass with scan speed, Bed preheating scans, See for more background technical information. [16] [17],

Electron gun beam focus model. to highlight resolution operational compromises between ; the higher the gun cathode voltage the tighter gun focus, so the smaller the beam spot size on the metal powder giving rise to a higher XY resolution ( lens adjustment can alleviate. See lens simulation [18]), yet also the higher cathode voltage the faster the electrons go, so the deeper the electron energy deposition/giving rise to deeper vaporization holes giving less vertical Z resolution, (used during Z axis error correction mode ). Also surface tension is correlated with temperature working in opposition to wetting effect flattening the metal blobs. See cathode simulation models [19] or[20] , See possible software solution Unified Accelerator Library (UAL) with supporting networks EPICS below.

Combining the above two models with the work piece metallic properties we can develop, a Work piece removal model and a Work piece melting model Beyond this we need a control system with monitoring and a network structure.

, ,

Possible Software ? "I don't think so?" "Who knows you knows?"

Those looking for entertainment might look at the open source Unified Accelerator Library (UAL) that has a 30yr track record of simulation and control of electron beam movement so this could be an option for a Electron beam focus model and a Control/Simulation approach. But UAL lacks thermal models and metal powder melting modeling so its main use may be to get the beam spot landing on the powder at the correct position and diameter defined in the G code from skeinforge. (You can down load UAL here [21], [22] Introduction here, [23] , Manuel for UAL's Design Toolkit called MADX where you can enter a hardware definition i.e. collection of coils along a beam start with two " solennoids " at 0.1m and -6 m, beam at 0m along latticeset at 3KW 100 micron diameter (MetalicaRap has 3 XY deflector coils for beam deflection, 2 "Solenoid" for beam lens's) then run simulation of beam with OFFLINE MODEL UAL 1.9 here[24], This hardware definition of coil positions is called the "lattice". The control ONLINE UAL 1.11 will them apply this simulation to the control of the electron guns in real time). ( I have failed so far I guess lots of play required? Rapatan.)( Ignore the following elements we don't have them in MetalicaRap ; BeamBean, electrick kicker,Kicker(gets beam to output from Accelerator), RF cavity, taylor map, wake, wriggler ( wobbles an electron beam so fast it becomes a laser beam)).

This has the advantage of being a heuristic system, which while simulating the beam movement simultaneously records models coils, guns, motors inputs; voltage values, current values etc. Then when you run the real world machine these form the drive instructions to the machine, any sensors picking up deviations are resolved through alarms or the software "reality checking" and thus improving the model. It also is designed as a multi user, multi platform software environment. Some draw backs may be over complexity of the system.

Possible open source fast Network "EPICS" ? for running UAL on, See here [25] [26] More Info here[27]

Possible Open Source thermal real time model software Code_aster Introduction here[28] , Download code-aster software (Windows) here [29], [30], Download code-aster software (Linux to compile) here[31], guide to documentation here [32], Documentation here SeeThermics module R5.02 booklet: / General Architecture D00301a.pdf In DDocsHTML (Down load following two links, unzip to same folder) [33] [34], Software Principles explained here[35] ,Aster documentation source here [36] , home page here [37] wiki[38],

MetalicaRap Construction; Physics Principles/Disscussion. .Metallurgy Disscussion. .High Voltage Disscussion

Metal Powder Printing; Powder issues

Powder issues

The initial test run prints will be made in stainless steel 30µ (Pre cool final printed parts from this powder is therefore likely to be 250µ) and chromium cobalt under 50µ 30µ?( Pre cool final printed parts from this powder is therefore likely to be 250µ)metal powder [39]supplier[40], and then later the challenges of Titanium 4µ powder will be considered (Pre cool final printed parts from this powder is therefore likely to be 20µ). See article on micro sls [41]. See example machine [42]. Though through subtractive machining we may be able to bring critical surfaces of most of parts down to 20µ.

The magnetic metals lead to magnetizing of the metal powders so should be avoided where possible, (the main magnetic metals are Iron, Nickel, Cobalt)

The metal powders are not good to ingest or breath in so mask should be worn, The metal powders may get caught in the fine folds of your skin so gloves should be worn.

All metal powders can burn easier than solid blocks, the active metals are most demanding; Titanium 4µ (other active metals include Aluminum, , zirconium ) , then the moderate range metals e.g. Cobalt Chromium 50µ and finally low range Stainless steel 30µ .General fire avoidance should be followed, Avoid sparks and open flames, Avoid dust clouds( through dumping action of powders), and use appropriate tools. Design principles of fire avoidance should include; appropriate grounding of equipment , avoid mechanical friction in design. For active metals consider glove box contained nitrogen clean up environment (Nitrogen from air extraction process).

Current status

Based in Copenhagen Denmark Electron gun test repstrap vacuum chamber including pumps and gauges under electrical maintenance.

We are particularly looking out for Metallurgists/Material Scientists, High Voltage Engineers and electron gun designers/support (Electron beam welding/accelerator) .

Get involved! the current team donate there free time, Current tech team; 2 software developers, 1 Ultra high vacuum metal deposition specialist, 1 material scientist , 2 High voltage system designer and 1 mechanical Design Engineer.

Do get in touch

Related Projects

Specialist Parts Chamber CF flange Electrical connectors, 1x 140KV 2KW , 2x140kV low current, 8x 30A 200V? coils , 8x SEM pickups low current low voltage,

2 windows

3x 12mm Motor shaft Vaccum chamber motion feed through. 10-5 Tor

Files and Parts

Sub Assemblies and Related

EBS=Electron beam sinterer/melting.

sequence - electron gun parts repstrapped EBS. Assembled tested in repstrap vacuum chamber. Metal powder deposition mechanism parts repstraped EBS . Gun depoosition assembled tested. MetalicarapVacuumChamber parts Electron beam sintered by our system. MetalicarapVacuumchamber assembled tested. 5 Elements assembled and tested.

Downloads

Photos and Drawings

File:MetalicaRap vers. 1.0.pdf

. . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

DON*T be SHY

You can download all 9 design files here : File:MetalicaRap vers1 9 of 9.pdf

Print the drawings add any modifications then scan and upload them to the site. We need to collaborate on ideas, this is open design.

Create and Upload your modified version of the above design drawings. No need to ask Be FREE'

the more the better the design, lets try for a dozen?

AMQ A Million Questions Section . . No need to ask just add your thoughts

Note diference between minimum feature size tolerance, part final tolerance, printer machining tolerance, printer repeatability, post cool down tolerance. So should we design mechanics around 400µ Tolerance so it will still work if we don't get to 20µ/50µ. many commercial powder printers end up printing at 250 µ pre cool tolerance spec. But 400 µ may be more realistic since after printing,part cools down Kinks, coils & warps even if many printer can achieve feature size of 50µ. Though with post print subtractive ebeam machining we could bring it back to 50µ? Depends on parts shape, use ..etc

How will the 10µ metal powder effect the mechanics?

Self reproducing tolerance critical parts design around? / buyin ?

CF flange 300µ CHECK WITH VAQUUM DESIGNER,

Cathode surface 10µ CHECK WITH EGN 2 gun cross point spec.

Threads ETC 10µ check Mechanical eng.

How do we avoid materials that out gass in high vacuum and so stop vacuum forming.? .....

Two suggestions from an Open source day Copenhagen, Use electric field to pull waste metal away switch on in between beam vaporizing pulses

so avoid bending beam.-ve may magnetize powder switching on and off , To protect guns have 2 motorized slotted sheets just above the powder, the hole where the slots cross is where beam enters -ve will slow beam down too much So N.G. as beam may reach 8000m/sn mechanical movement approx 1m/ S

Cathode tungsten pin is heated to 2500o C electron source overheating surrounding mechanical construction once been at 2500o C for 2 days.

Ideas to reduce heating of surroundings 1. Not wire connection but use RF aerial to Aeriel connection, insulator which?

Principles behind problem Types of energy exchange EM radiation , no convection (vacuum) , Conduction through supports.?

First layers are tricky to print WHY residual tension left in metal. powder thermal pre-treatment to degass and avoid powder balls and good flow.

..

..

DFTP Don't forget the post . No need to ask just do those "ten minutes of fun" mini research projects

- seach in google scholar for METAL POWDER BEAM any thing bout why the first layers are so tricky to print and result in most residual stress. [43], [44]

..

More Examples

Practical manufacturing walk through

Given Electricity is 2kwh per hour .5Euro/hr

Part A Stainless size 300x300x200mm 15Kg

10µ Stainless powder (40Euro/kg) melt print 100µ Z layer thickness

1 minute per Z 100µ each layer heated melting-point – 20 0C then printed by beam

3.4 minute per Every 10th layer Z axis correction ; SEM ( part assumed to occupy 1/9 of whole print area; 1/9* 300*300=10 000mm2 measurement at every 10µ, SEM picture 500x500 pixel so 5mmx5mm, So for 10,000mm2 need 400 SEM pictures 10,000/25= 400 4x pictures from 4 picups gives effect of different angles? for 3D picture reconstruction so real distances, 400 5mmx5mm pictures, 250ms a picture 400x.25 Sec = 100Sec or 1.66 min ( Risk of underestimate factor x100 )

Remove metal by Vaporization 1ms per 70µ diameter spot area 4000x10-6 mm2 ( 850µs duration & 150µs beam movement) 1/10 of part high(Risk of underestimate factor x2) ( 1/10*10 000mm2/ 4000x10-6 mm2= 1x105 spots 1x105 spots*1ms= 100Sec 1.66 min Time so far 200* Z correction layers 3.4 Min each + 1800 printed layer 1min each = 2480 min ( 1.7 days)

To add a 40mmx4mm = 160mm2 bearing surface by removing up to 40µ to achieve 0.1µ specification Ion beam abrasion 20min per 1mm2 160*20min =3200min

Time total so far 200* Z correction layers 3.4 Min each 1800Min + 1800 printed layer 1min each 1800 = 2480 Min + ion beam bearing surface 3200= 5680( 4 days)

Cost 665 Euro materials 600Euro Electricity 65

Part B Aluminum size 300x300x20mm 1.5Kg

Aluminum 15Euro 10µ powder, melt print 100µ Z layer thickness

Time 20* Z correction layers 3.4 Min each + 180 printed layer 1min each = 248 Min 4 hours No ion beam abraison Cost 25 Euro materials 22 Euro Electricity 3 Euro

Further manufacturing walk through

Powder

injection molding powder

Aluminum powder 15 Euro/Kg 10µ

Carbon chromium 40Euro a kg. 74µ

Stainless powder 40Euro/kg 10µ

Self replication

Self-replication of a vacuum chamber runs into the "how to make a match box inside a match box problem". Some say the "lots of small rigid parts joined together" approach -- illustrated on the right -- has "too many joins" for a vacuum chamber. Would a relatively soft material in the gaps between parts -- like the Pb lead between parts of a stained-glass window -- compress enough to make it air-tight? Normally use copper wire to make up "CF flange".[45]

As the main consideration is avoiding non MetalicaRap conventional machining, can you make the copper wire pinch/seal of a CF flange out of the edge of a purchased plain rectangular plate? Is there a better approach?

NB. It can also weld finished parts together placed in the chamber, the chamber is twice as wide XY as build area approximately, as it needs space for removable metal powder hoppers!, can you use this extra space?,

Chamber 1.3m high, 1m wide, 0.6m depth powder build chamber is 0.3m High 0.3m Bredth 0.3m wide

Door size is up to you, could be a full side eg 1.3m by 1m.

Future Development .....Green Tech..... Focus on products that serve the environment

A solar cell production plant design that MetalicaRap will be able to print, that will then utilize MetalicaRap's vacuum chamber and beam for solar cell manufacturing processes of; spluttering EBPVD , deposition rate of a few micrometers per minute / electron beam heat source for evaporation / possibly a micro pulsed electron deposition process, and so produce thin film CIGS solar cells at under 11 cents per Watt peak. We have had some interest from solar cell production professionals already!

So Solar cells cost for a family 3 Bed house; Average Electricity usage 4200KW per year, 4200KW/365days*4.93 Equivalent Hrs peak sunshine= 4200KW/1800Hrs=2.3KW peak of solar cell panels required, at 11 cents per Watt peak the solar cell's would cost 253 dollars from MetalicaRaps plant, cost of inverter plus extras 1300 dollar, so it may offer an uninstalled system at under 1,600 dollars,( current price for uninstalled system is around 14,000 dollars (jan 2011)).

(Calculation based on cloudy areas of world, 1KWatt peak solar panel system under 4.9 hours peak sunshine per day gives approx 1800KWh per year, A desert area at low latitude would be up to twice as good as this.)

Design of a device to produce technical gases to suppl SLS printers as well as other equipment. Gases can be separated by selective distillation after liquefying them using the Linde process [46].

Critical Design Review, Review of decisions made so far

In chronological order

1.metal.......................... Vs ..composite. ........... .........Why .Metals needed for high stress high temp contexts , engines, solar plants.. -ve ........................ +ve

2.additive.Sintering........ Vs Subtractive EDM?.................Why Tool path manual intervention required.Consumables......... -ve ..Powder management ............ +ve

3.ebeam..Vs laser .....Why A)laser below 50W,small size part 5x5x5cm,slow B) Laser above 150W cost, permit , Wall plug efficiency , optics .-ve .not so cool , difficulty diagnostics...+ve solar cell printer possible

4.powder...........................Vs foil..........................................Why foil waste removal.................................-ve .Harder solid parts.& powder management...... +ve

5.vision & correction sub. Vs one pass blind process ... ....Why .reliability Verifiable tolerance............................................. -ve ...Complexity..................... ................ +ve

6.gravity hopper................ Vs twin chamber........................ Why easier prep simpler construction IS THIS TRUE............ -ve powder overflow management +ve

7.two guns ....................... Vs one gun................................Why So SEM near table Sensors PIN Diodes 164$ each not 64x PINdiodes -ve complexity +ve old tech.

8. Liquid cooling for 5KW gun Vs passive cooling........Why .Power of gun run for a long period demands this....IS THIS TRUE............. -ve Complexity............... +ve

........................................ Vs ...............................................Why ............................................................................................... -ve ..................................................... +ve

........................................ Vs ...............................................Why ............................................................................................... -ve ..................................................... +ve

....................................... list in importance order, bold text indicates more thought required

Useful links

EBM introduction [47]

Images EBM / EBW [48]

General background Videos EBW see here [49] EBM technical background lecture See here [50]

Discussion of Advantages and Disadvantages of different Tool head processes.