Mendel heated bed

Release status: Experimental

| Description | Mendel Dibond heated bed

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | Heated-bed-design-files.zip

|

| External Link |

Introduction

If you build fused-filament-fabrication parts (the technology that RepRap uses) at room temperature, they have a tendency to curl as they cool from the bottom up. This is caused by higher layers shrinking as they cool, and bending the already-set lower layers upwards.

Different plastics suffer from this problem to different extents. ABS is quite bad. Polylactic acid (PLA) is quite good. Indeed, if you make a single PLA part in your RepRap, curling probably won't be a problem at all - the part will stay warm enough from one layer to the next to eliminate the problem almost completely.

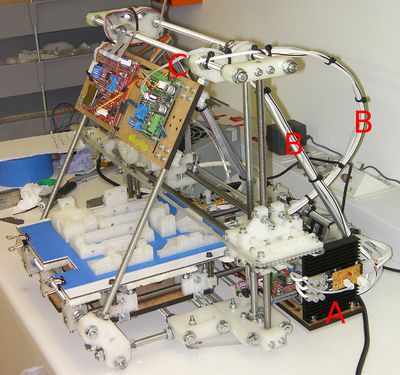

But if you build whole trays of parts (as in the picture) then, even using PLA, you can get some curling. The cure for this is to build on a bed that is heated.

This heated bed is primarily for making polylactic acid (PLA) parts. It probably won't run hot enough for ABS. But that guess is subject to correction by experiment.

The CAD and other design files for this heated bed can be downloaded from here.

This device was from an idea by Nophead.

Cutting out

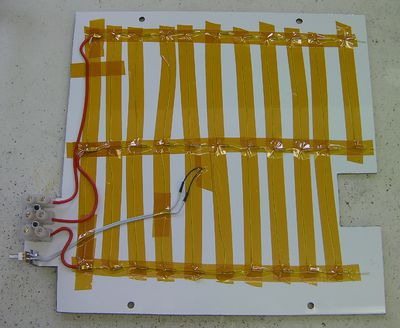

The main part of the heated bed is made from Dibond. This is a sandwich of LDPE between two sheets of aluminium. It is very light, very stiff and very flat - all required properties for a RepRap build bed. The bed is made from a sheet of Dibond with heating wires and insulation attached underneath.

The plastic in the sandwich is not the world's best thermal conductor, but the bed is thin enough that it seems to work well.

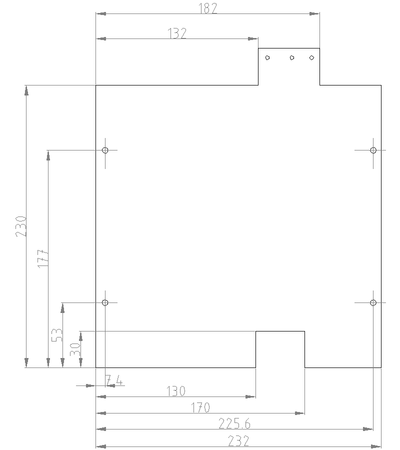

I bought my Dibond from these people who kindly cut it into rectangles of 232x260 mm for me. It is pretty widely available as it is used for making signs and exhibition stands and such like. It's also pretty cheap.

This shows the pattern to be cut from 3 mm thick Dibond (the .dxf file for this is in the CAD download). The shape is exactly the same as the standard Mendel build bed, but with the addition of the tab at the back for mounting electrical connections. The dimensions of the tab are not shown because you may have to change them a bit to accommodate the electrical connectors you use. My tab was 30 mm deep.

Two of the three holes in the tab are for mounting a three-way chocolate-block screw electrical connector - get a chunky one; it has to handle a significant current. The third is for a small right-angled bracket to mount a connector for a thermistor that will be used to measure the bed's temperature. Virtually any small two-way connector will do for that. Make sure that the connections (which will be on the underside when the bed is in use) do not foul the two reprapped parts and the M4 screws through them that hold the right-hand Y-axis bar at the back of your Mendel.

You could try cutting the Dibond in a laser cutter, but the aluminium may well give trouble if you do. I found that a bandsaw worked best. If you saw out the shape, gently clean the edges with a file afterwards to remove any lips and burrs.

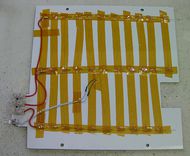

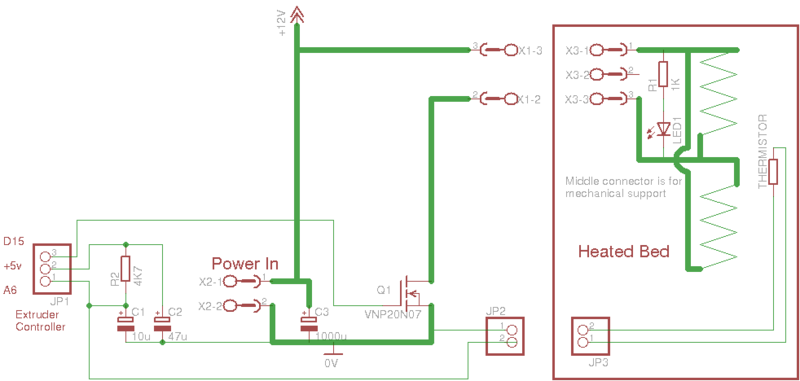

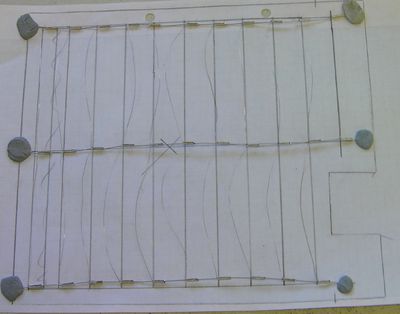

Wiring up

The first electrical question that arises is obviously: how much power is needed to keep the bed at the right temperature? I run my bed at 55oC (though see below), and that seems to need a little under 100 W at a duty cycle of about 70%.

If you are going to run the bed at 12 volts, then this implies a bed resistance of 122/100, or about 1.5 ohms.