MakiBox

Release status: working

| Description | Full case 3d printer

|

| License | ???

|

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

Introduction

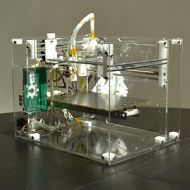

It’s the first 3D printer designed from the ground up to be simple, completely self-contained, reliable and most important of all, affordable!

The MakiBox A6 utilizes a desktop-friendly, partially enclosed design, within a space barely bigger than a sheet of A4 paper. The filament fits on a spool-holder at the back of the MakiBox, keeping things neat and compact.

The MakiBox is designed to be more simple and reliable than any other in this class. Instead of using complicated belts and pulleys, it uses simple drive screws, reducing the number of parts, the cost, and the assembly and maintenance time. The most difficult parts will come pre-assembled, such as the extrusion head or the drive shaft coupling so that the kit assembly is no more difficult than IKEA furniture. Build time is about 2-3 hours.

Initial development started with a successful crowdfunding campaign at the end of 2011 and since then ran through some beta stages with increasing performance and quality. Mass production of the printer is just about to start (as of July 16th 2013) and pre-orders should start shipping within the month.

Specifications

- Models: LT (without heated bed), HT Acrylic/Stainless steel (with heated bed)

- Printed Parts: None on production model

- Non-Printed Parts: Laser cut acrylic or stainless steel panels. POM (generic Delrin) injection molded brackets and gears.

- Electronics: Printrboard Rev B

- Material Cost: ???

- Cost: USD 200 (LT), 300 (HT Acrylic) or 350 (HT Stainless Steel) + shipping. Early buyers got $50 flat shipping fee. May be additional local taxes or fees. (Partially assembled.)

- Outside Dimensions: 290mm wide x 235mm deep x 235mm tall (without filament loaded)

- Extruder: "Zen Drive", takes 1.75mm filament and drives it through a tube to the hot-end

- Hot-End: own development with a 0.4mm or 0.5mm default nozzle (0.3mm available in the future)

- Printing Size: 110mm x 150mm x 90mm

- Precision: 0.04mm (position/printing)

- Speed: 40-60mm/s (position/printing)

- Head: XY

- Bed: Z

Specialities

- Full acrylic or optional stainless steel casing.

- Mass-produced injection-molded precision parts

- Optional pellet to filament drive (named "Ramen Extruder") creating 1.75mm filament (still in development)

- Trapezoidal drive shafts, no pulleys

- Makibox HT, USD 300, has a heated printbed and can print in ABS, PLA, or any similar material

- Makibox LT, USD 200, has a non-heated printbed and can print in PLA only

- with the 1000th sale it was decided to open source CNC-able design files in the future, to allow for better modding and self-production of the parts

Development Process

MakiBox started to create a self-contained pellet driven 3d printer, but while the development the pellet driver "MakiBox Ramen" and the actual 3d printer "MakiBox A6" were disconnected, the pellet driver does not feed the printer extruder direct due discovered difficulties:

- The problem is that you do need something to separately pull the filament from the (pellet) extruder and push it into the printer (extruder), if you are doing a feed tube and not direct printing. The reason for this is that the flow will get stuck extremely easily from the extruder with small amounts of back pressure. There is always somewhere in the feed that the material is molten enough to mushroom against the back pressure. -- (Jonathan Budford, 2012/12/24)

So the pellet to filament extruder ("Ramen Extruder") will be a separate device that creates and rolls filament on a spool and then once rolled, the filament can be used for the actual printer "MakiBox A6" (or any other printer).

Links

- MakiBox.com, store, community forum and detailed blog