LaserCutXAxis

General

This page and its peers should guide you through assembling a RepRap Lasercut Mendel from the TechZone kit, or from parts you have laser cut which are the same as the TechZone parts. It is a work in progress, and needs some help, feel free to edit this document to add comments of you your own, or contact us [here] and send us messages asking us for better clarification or details.

I am starting by posting the pictures I have, and over the next few days, I will fill in the instructions and detials (6 April 2011)

Thanks,

Lambert (TechZone R&D/Support/Documenter)

You can access this page and it's peers (for the other parts of the Lasercut Mendel assembly from the TechZone Lasercut Mendel Page

Contents

Whene assembling the X Axis, assemble the parts just finger tight, and into aproximate areas. When it is all together, we will fix things by measurements, and tighten them up.

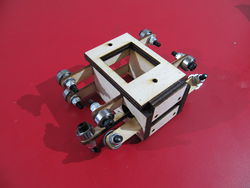

X Carriage

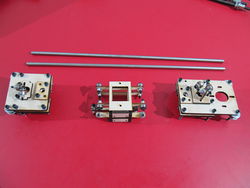

On the left is a picture of the parts used to make the X axis carriage (some people call it a shuttle) It is shown assembled on the right:

Start by attaching the bearings to one end of the 360 bearing spring arms. The stack goes bolt, washer, wood, one or two washers (depending on spacing needed to center on rod), bearing, washer, and nut. Slide the spring arms through the slots in the carriage on the 360 side aligning them so that each bearing will make contact with a rod running through the center. Attach bearings to the other side of the 360 spring arms with the same placement as the first end. Finally attach the bearings to the 180 spring arms with the bearings on the outside of the carriage.

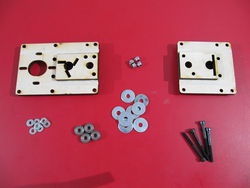

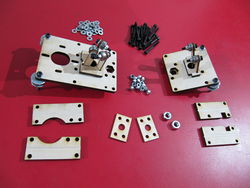

Z180 and Z360 Degree X Axis Idler and Motor Mount

We use the parts shown on the left to make the assembly shown on the right.Start by attaching the bearings on the outside corners of the X idler and X motor mount. The stack goes bolt, washer, wood, fender washer, washer, bearing, washer, fender washer, nut. If the belt is too tight between the fender washers you can add an additional washer between the bearing and fender washer for extra space.

Next attach the bearing spring arms on the 360 and 180 side the same way as you did the carriage above.

Now you are ready to attach the smooth bar clamps and the Z nut retainer. Start by putting bolts through the X motor mount and X idler to their matching smooth bar clamps. The clamps with the notch go on the idler and the clamps with the round cut out go to the motor end. The nut retainers are the rectangular pieces with 4 smaller holes in the corners and a larger hole in the center. When you put the bolts through the clamp that also go through the nut retainer make sure you have the nut retainer in there as well. Leave it loose for now. Once that is done put the 8mm nuts in the spots for the nut retainer and tighten down the bolts on the nut retainer enough that the nut doesn't come out, but not all the way yet. Tighten everything else down most of the way, but make sure it is still loose enough that the smooth bars can slide in easily. The nut retainers have four holes so that they are symmetrical, but not all 4 holes need a bolt. Only the spots that have bolt holes on the motor and idler pieces need bolts.

Put them together

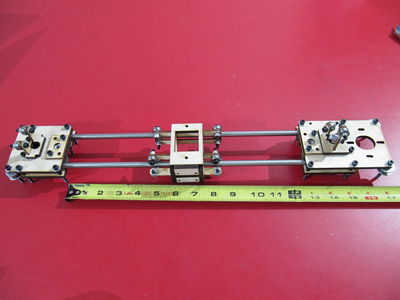

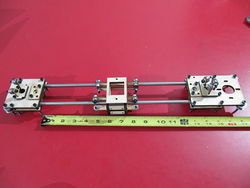

We use the parts we assembled above (shown on left) to complete the unit as shown on the right.

Put the idler end on your left and the motor end on your right with the carriage in the middle with the 360 side facing you. Slide the two smooth bars into the idler end until the ends of the bars are about to the end of the clamp. Tighten the bolts on the clamp down. Now put the carriage onto the smooth bars keeping the idler on your left and the 360 side of the carriage toward you still. Now slide the motor end onto the smooth bars till the bars are about to the end of the clamp. Tighten the bolts on the motor end clamp down enough that it will hold, but leave it loose enough you can still slide it on the smooth bars. we will tighten it down the rest of the way after we have it on the Z axis and have adjusted it to the correct length.

Final adjustment and tightening

Before you tighten down the X axis you need to assemble the Z axis. After you have the Z axis assembled and the Z axis smooth bars square and parallel you can adjust the width of the X axis. You want to adjust the width so that the bearings on the 180 side ride in the middle of the 180 Z smooth rod. Once it is the correct length tighten everything down to hold it in place. Check that the Z smooth bars are truly parallel by driving the X axis up and down and make sure it stays near the center of the rod from bottom to top. Now measure the height of the X axis above the frame on one side and adjust the other side of the X axis up or down so that it is they same height. You will want to recheck this and make sure it hasn't moved as you attach the Z drive belt.