LaserCutFrame

General

This page and its peers should guide you through assembling a RepRap Lasercut Mendel from the TechZone kit, or from parts you have lasercut which are the same as the TechZone parts. It is a work in progress, and needs some help, feel free to edit this document to add comments of you your own, or contact us [here] and send us messages asking us for better clarification or details.

I am starting by posting the pictures I have, and over the next few days, I will fill in the instructions and detials (6 April 2011)

Thanks,

Lambert (TechZone R&D/Support/Documenter)

You can access this page and it's peers (for the other parts of the Lasercut Mendel assembly from the TechZone Lasercut Mendel Page

Contents

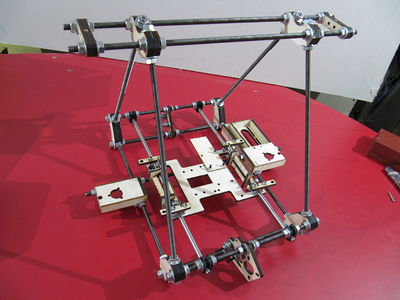

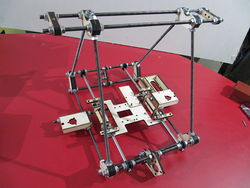

We Assemble the Frame as Units, the Top Unit, the Front Unit and the Back Unit, then we put them together. To begin with, we assemble parts just finger tight, and into aproximate areas. When it is all together, we will fix things by measurements, and tighten them up.

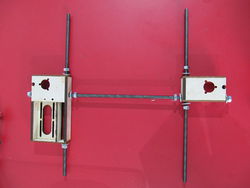

Top Unit

On the left is a picture of the parts used to make the top unit:Simply thread the inside nuts onto the bars, then washers, followed by the top vertice pieces, more washers and the outside nuts.

Make the parts just finger tight for now, we will get the exact placement and tighten it up a little more at a later time.

It should look something like the photo on the right when you are done assembling this.

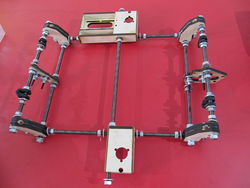

Front and Back Unit

The parts Used to make the Front unit are pictured on the Left, and an assembled front unit is shown on the right. The parts used are:Front Unit

- (2) Vertices

- (1) Y Idler

- (2) Y Smooth Bar Clamps - printed parts

- (2) threaded rods, two of the four shortest rods

- (16) 8mm Nuts

- (16) 8mm washers

Back Unit

- (2) Vertices

- (1) Y Motor Mount

- (2) Y Smooth Bar Clamps - printed parts

- (2) threaded rods, the other two of the four shortest rods

- (16) 8mm Nuts

- (16) 8mm Washers

Idler and Motor Bearings

- (4) 4mm X 40mm bolts

- (8) 4mm Fender Washers

- (12) 4mm Washers

- (4) 4mm Nylock Nuts

- (4) Bearings

Once you have the bearings attached you can put together the front and back units. Start with the idler unit. First slide the idler to the center of the bars and put washers against it on each side and then tighten the nuts down (finger tight for now, we will tighten it the rest of the way while we are doing the squaring later). Next put on the nuts for the inside of the smooth bar clamps on the top bar (the top bar is the one closest to the point on the Y idler) followed by washers. Then slide on the smooth bar clamps and the washers and screw on the nuts. Now put on the nuts and then the washers for the vertice pieces on all 4 bars. The vertice pieces go on so that when it is sitting on the point near the bottom bar the top of the vertice is pointing towards the outside (same direction as the point on the idler). Once you have the vertice pieces in place slide on the washers and finger tighten the nuts. The back unit goes together the same using the motor mount in place of the Y idler in the above instructions. The part the motor mounts on goes to the outside and the top is closest to the small point for mounting the opto end stop.

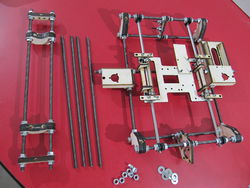

Install Z axis Pieces

The parts shown on the left are used to put the bottom of the frame together,

The parts Are:

From Above

- Front Unit

- Back Unit

Additional Parts

- (1) Z Axis Combo unit

- (1) Z Axis Driven unit

- (2) 8mm Threaded rod to connect the front and back units,

- (1) 8mm Threaded rod for the Z unit.

- (16) 8mm nuts

- (16) 8mm washers

At this point I like to install the Y axis before attaching the top of the frame.

Attach the Top Unit

The parts shown on the left are used to put the rest of the frame together,

The parts Are:

From Above

- Top Unit

- Bottom Unit

Additional Parts

- (2) 8mm Threaded rod to connect the top and bottom units,

- (16) 8mm nuts

- (16) 8mm washers

Squaring, and Truing the Size/Shape

To adjust the frame you simply make lots of measurements and adjust the nuts until all the bars line up where they should be. You can do this as the frame now, and then adjust the Y axis after it is installed, but I like to do them all at once, so I wait until the Y axis is installed then make these adjustments (click here for Y axis instructions). This is much easier to do if you have the machine on a flat surface. I know this from experience, there was a machine I was building, and I built it on top of all the clutter and tools which had accumulated on my work space... I spent WAY too much time trying to get all the measurements to work.

The front, top and back units are all adjusted to have the same width, as measured on the threaded rod that forms the triangles. I set my bars to 175mm apart, you can use a different number and that is OK, if you go too narrow then the build plate won't fit and if you go too wide the bars won't be long enough. I measure it from center to center on these rods near the vertices. Each unit should be measured near both of the rods that make up that unit. As you adjust the front and back unit, you may need to loosen or tighten the Z bar that is parallel to them in the bottom. I don't ever measure this Z bar, but rather when I have both the front and back units adjusted, I simply snug the nuts for this bar as well (and threadlock it).

After all the adjustments are made on the Frame, I like to put threadlock on, so that the future vibrations won't cause any shifting of the nuts.

Now I adjust the Y axis.

Then I adjust the 180 side so that it fits freely in the 180 bearings for the entire travel of the Y axis. Sometimes, the second bar is not perfectly parallel to the first - this is OK and it is a result of any imperfections in the printed parts in the Y axis. The important thing is to remember that the whole axis will travel the path of the 360 bar, and the 180 bar will keep it from falling, or bumping upwards.

Any nuts or bolts on the Huxley - as it is assembled so far - should now be tightened and threadlock applied if appropriate. (ie, you don't need threadlock on any nylocs, or on the nuts which are embedded in plastic parts)

The Y Motor Mount and the Y Idler are adjusted and threadlocked into place as you install the Y belt.