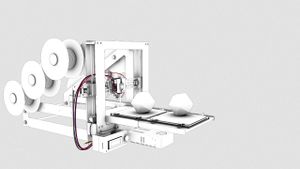

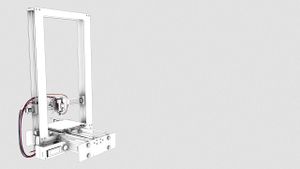

HELLOPRINTER

Open Source Multi-Maker (3D printer, CNC, Laser cutter/engraver)

Based on the work of josef prusa, model prusa I3 link: github /josefprusa/Prusa3

Base model characteristics:

Build Size: 200mm x 200mm x 200mm Resolution: Base nozzle has 3 diferent resolutions 0,2 , 0,3 and 0,5, if you choose the chess extruder you can go as high as 2mm, ideal for the bigger versions. Z Resolution: Best achieved with a normal calbration 0,1mm , when well calibrated you can reach resolutions of 0,01mm Materials: ABS, ABS-PC,ABS-Carborn, Glow In The Dark ABS and PLA, PLA, HIPS, Laywoo, Claywoo, Nylon, PVA and others Speed: Up to 100mm/s (tested with 2000mm/s set up and worked) Prepared for automatic bed levelling Monkey Extruder - Super lightweight Dual extruder ( motors with half the weight of a nema 17) with the capability of separating both nozzles up to half the bed lenght, making possible the print of 2 objects in diferent materials or colors at the same time saving 50% of the building time for not having to do the same path twice. The filament is visible all the way to the nozzle, making easy to do mantaince and cleaning Stainless Steel Structure - Needed for having enough weight to withstand the CNC function Magnétic Sensors for precise home positionning Ramps 1.4 and Arduino Mega 2650 - 5 motor drivers (dual Z Driver and Dual Extruder), 3 12v exits for FAN, BED and EXTRUDER combinations and support for 4 servos. LCD with SD card reader for Autonomouse print Print speed control during print Marlin Firmware

Software recomended Kisslicer or Slic3r and pronterface

GITHUB LINK WITH BUILD MANUAL: /hello3dprintingworld/helloprinter