Fused filament fabrication

FFF (fused filament fabrication, also called fused deposition modeling, fused deposition method, FDM) is an additive manufacturing technology.

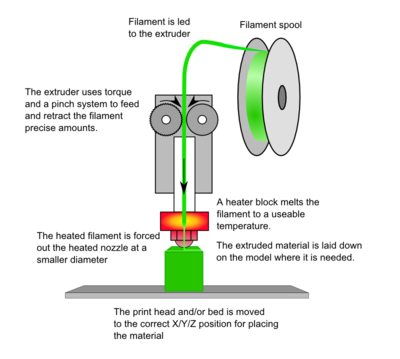

A fused filament fabrication tool deposits a droplet of one material (plastic, wax, metal, etc. -- see PrintingMaterials) on top or alongside the same material making a joint (by heat or adhesion).

Because objects printed with FFF are layered, they have a grain like wood. Even when printed with an infill rate of 100%, such objects are not quite as strong (in some directions) as others. Test show that printing "the same" object in different orientations, with different infill patterns, can give differences in strength of almost 2 to 1. An "interlocking" infill pattern seems to give more strength. [1]

RepRap forum: "Questions about durability of repraped models"

The phrase "fused filament fabrication" and its abbreviation to "FFF" is typically licensed from Adrian Bowyer

under the GPL.

More precisely, we call it "fused filament fabrication" when we have to call it something besides printing..

We don't make a big deal about licensing, and generally don't play control and ownership games with RepRap stuff. --Sebastien Bailard 02:18, 16 November 2010 (UTC)

The phrase "fused deposition modeling" and its abbreviation to "FDM" are trademarked by Stratasys Inc.

The precise shape of the infill, and the small airgaps, is still under investigation. ("Spot on flow rate").

Materials used with FDM

Most popular are PLA and ABS, but (non-comprehensive) also printable:

Nylon, HDPE(ABS HDPE blend), PCL, Polycarbonate.

See also Category:Thermoplastic.

Also some low melting point metals like woods metals have been extruded for development of printable electronics.