FoldaRap Buyers Guide

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

This project was for myself, as I need/want a RepRap that's easy to carry around and for the challenge of making a folding 3d-printer. But I believe in open-source and sharing and all the revolution behind that. Thus I try to well document it, in case others want to make one; to acknowledge all the things we own to those who went before, and to encourage those who come after to do the same.

On a more long-term view, I don't plan to create a company out of it, I'd better hope to see it grow on itself in the wild, just by indicating how to source it. I have more fun in designing stuff than marketing it, nonetheless I may try to sell few beta-test kits (bulk ordering is good for prices), eventually via a crowdsourcing campaign or by request, maybe with the help of my hackerspace. Just for the experience of it and to say I can push a project to that point :D (edit : done !)

(almost all the projects I did during my design studies could have done something, but I never found the time for that and they ended sleeping in their drawing books which is sad; while now I have taken the habit to publish everything, even an old one sometimes).

"Ideas are like living things and breed happily in an open-source context" as I like to think ^^ (on the same spirit I like this comment from User:Adrianbowyer)

Contents

Bill Of Material (BOM)

Total end cost for 1 machine : ~500-600€ when you include all taxes and shipping costs. I suggest you to make group orders with friends and always try to source locally.

Hardware

5 20x20mm beam 6mm slot 200mm - Motedis or see Aluminium_profile_Suppliers 6 20x20mm beam 6mm slot 300mm 47 M4 T-nut for 6mm slot - Motedis

49 M4x8 round head bolt - Fix'n Vis Round Head Bolt 2 M3x4 / Hotend-heatsink(2) Fix'n Vis Bolts 15 M3x8 bolt / Z-motors (4), Y-motor (3), X-end-idler (2), psu (4), male plug (2) 2 M3x10 bolt / Hotend-heatsink (2) 6 M3x12 bolt / X-idler (1), extruder-idler (3), Y-belt-clamp (2) 4 M3x16 bolt / X-motor (3), extruder-fan (1) 7 M3x20 bolt / X-carriage (3), hinges axis (2), Y-idler (1), extruder-idler (1) 3 M3x30 bolt / bed leveling (3) 1 M3x35 / extruder spring (1) 4 countersunk M3x12 bolt / bed assembly (4) - Fix'n Vis Countersunk Bolts 28 M3 nut / hinges (2), X-carriage (3), X-idler (2), Y-carriage (6), Y-belt-clamp (2), extruder-idler (2), plug (2), extruder-fan (1), bed-plate (4), psu (4) - Fix'n Vis Nuts 3 M3 nylock nut / bed leveling (3) 5 M5 nut / extruder-idler pneumatic fitting (1),z-rod (4) (for the Z nylon nuts can be slightly better) 15 M3 washer / x-motor (3), x-idler (2), extruder-idler (2), y-idler (2), y-carriage (6) - Fix'n Vis washer 2 230mm threaded rod M6 - Fix'n Vis

1 extruder spring - RS751483 or see Springs 3 bed springs - RS 751607 1 length of spiral wrapping band for tidying the wires - RS227874 7 faston ferule - Radiospare to crimp the cable for the plug and the switch

2 polymer coupling - See this thread (ebay / emakershop) 6 linear bearing, LM6UU or if you can Igus RJMP-01-06 - See Bearing 4 300mm smooth rod 6mm - (can be salvaged from usual scanners and printers) or see Smooth-rod 4 603zz bearings / X-idler (1), Y-idler (2), extruder-idler (1) - See Bearing 1 600mm T2.5 belt 5-6mm wide - RepRapWorld or see Belts_and_Pulleys 1 700mm T2.5 belt 5-6mm wide 2 T2.5 pulleys - Paoparts or see Belts_and_Pulleys 1 PTFE Tubing for bowden extruder (2mm inner diam. and 3mm outer), 300mm long - See Bowden 2 Pneumatic fittings for 3mm tubing, with M5 thread - See Bowden or emakershop / I'm using the MA12-03-M5 but others can work 1 direct drive gear - Maritime-models (see Drive-gear) 1 140x140mm Huxley heatbed alu plate 4mm thick - Paoparts 1 roll of kapton - See Kapton Tape#Vendors 20-30 zip-ties

Electronic

5 nema14 stepper motors - [1] 1 usb to mini-usb cable - [2] 3 miniature microswitch endstop 20mm - [3] 1 standard male plug IEC C13 C14 - RS 5392045 1 standard female cable - EU/C13 - UK RS6266739 / US RS7316163 1 big blue switch - RS 5287858 1 RepRappro Hotend - emaker 1 40x40mm heatsink - RS 6744769 to make a more compact hotend 1-2 small fan (40 x 40 x 10 mm), for the hotend (can be bought with one) and the extruder motor - RepRapWorld or see Fan 1 100k thermistors - Mouser 1 m of 18AWG wire (300mm red, 300m black, 210mm green) for the switch/plug - Read also WiresAndConnectors 1,5 m of 22AWG (red or black) for the hotend heater 10 m of 26AWG (3.6m red, 3.2m green, 2.0m blue) for the sensors and fans

1 Melzi board [4] 1 12V power supply : 5A or 10A (for heated bed)

or

1 Azteeg_X1 board - [5] 4 stepper drivers 1 12V power supply : 10A or 20A (RS 7066316 100*150*35mm)

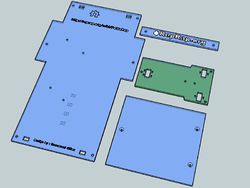

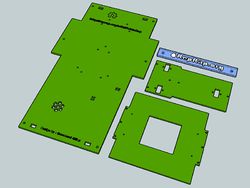

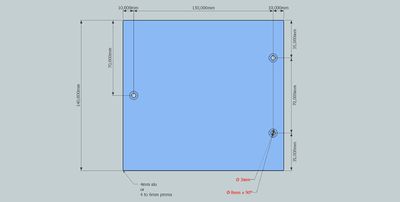

Laser cut parts

See the github repo and eMakerShop, you can have them from Ponoko too

1 electronic under-plate 3-4mm thick 1 bed-plate 4-6mm thick (acrylic or aluminium) 1 Y-carriage 1 reprap.org plate 160x20mm, 2-4mm thick (+2 T-nut and M4x8) - optional but make a nice reference to the wiki :)

These parts can also be made by hand with simple tools.

Printed parts (total : 20-21)

See also the github repo

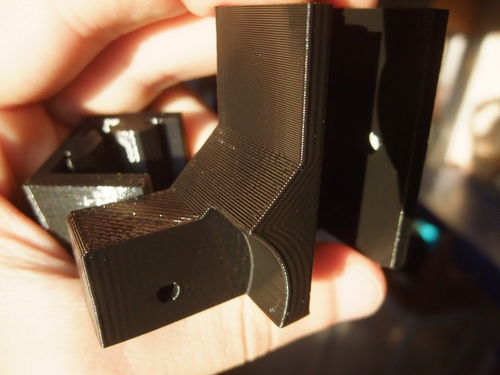

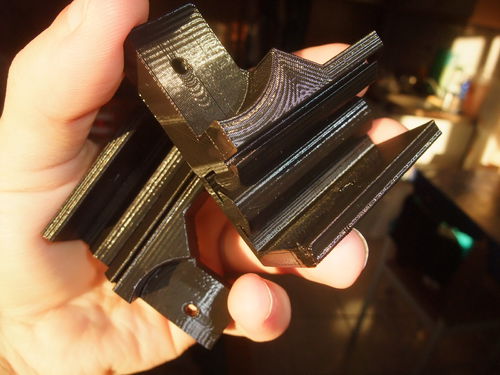

foot front left foot front right foot rear left foot rear right hinge-inner left hinge-inner right hinge-outer left hinge-outer right z-motor-bracket left z-motor-bracket right z-top left z-top right y-motor y-idler y-belt clamp x-end-motor x-end-idler x-carriage extruder-idler board mount

Other

Heated-Bed

For the aluminium heated bed add :

1 aluminium bed plate (4mm thick) 1 100k thermistors - Mouser 60cm of 26 AWG wire (blue) 1 peltier element 12708 (40x40mm is enough) - ebay

Padded suitcase

- EU : http://www.abylon.fr/valises-etanches-olycase-61/olycase-500-1171.html

- FR : http://www.vexi.fr/valises-plastique/etanches

- US : http://www.amazon.com/Nanuk-Case-Cubed-Foam-Black/dp/B003JH7ZU4/

How to replicate a FoldaRap !

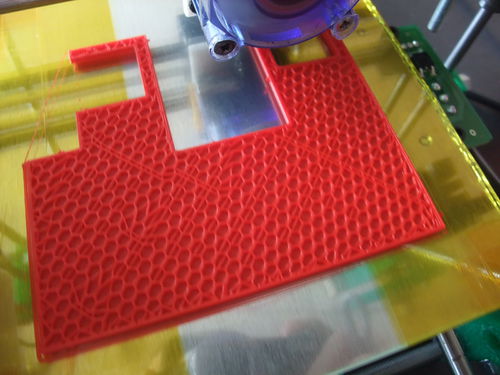

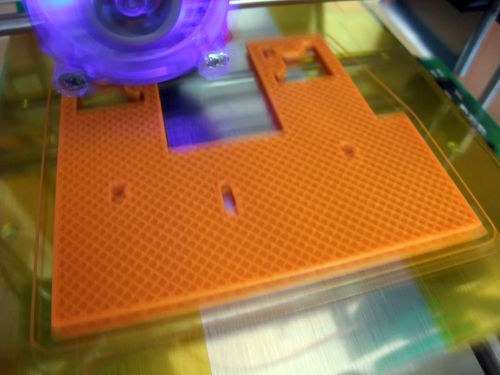

If you can print your own parts it will take ~400gr and 22h at ~30% infill

Material

I'd recommend PLA over ABS.

It's maybe only required for the parts that act as sliders on the aluminium extrusions (x-motor, x-idler), but there is still some big parts (the feet).

Recommended settings

- Nozzle diameter of reference : 0,5 mm

- Layer height : 0,25mm

- It is advised to have a well calibrated machine (+/- 0.05mm on measured parts) : http://forums.reprap.org/read.php?282,159683

Infill : 30-35% hexagonal or rectilinear or any dense pattern you like.

I recorded this little video where I'm playing with some parts freshly printed, to show what to expect about the tight tolerances.

<videoflash>rRXyc5I8yfo</videoflash>

The part that slide under it's own weight (16gr) have been slided back and forth a few time.

Fully assembled machines

Not yet.

Partial or complete kit

- The second batch is now available on Goteo : http://goteo.org/project/foldarap-peer-to-peer-edition?lang=en !

Webshops

- http://www.paoparts.com/fr/36-foldarap

- http://spares3d.com/index.php?id_category=17&controller=category

Printed parts

- http://mendbot-shop.byethost11.com/plastic_parts.php (quality of printed part is not known)

- http://www.emakershop.com/browse/listing?l=559

Misc.

- A draft BOM is on Kitbom

- My spreadsheet is roughly the same as the following lists but a little outdated.