CoreC

The CoreC is a 3D printer designed for the medium/large manufacturing that operates within a network for a just-in-time and local production, managed by a remote SW able to optimize production by guessing market trends. FDM is the predominant technology in 3D printer solutions, thanks to its cost/benefit ratio. The goal of our the project is to bring the advantages of FDM technology to its next level, from an amateur stage, in to the production of goods for the entire community.

Release status: working

| Description | Fused Deposition Material

|

| License | CC BY-NC-ND 4.0

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | 3D Printer

|

| CAD Models | Yes

|

| External Link | see below

|

Contents

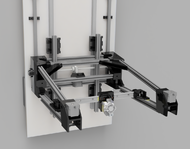

Design

The machine has been designed to help the optimization of the company spaces, exploiting the verticality of the machine. The CoreC system is assembled inside a 19" rack server and can move over the entire height of the cabinet. Its design is strong and robust as an industrial machine, this is the reason for choosing a server rack, so that it can be both slim and light in its components. The printer structure permits a rapid change of the printing module, thanks to the fusion of all mechanical and electronic component in one unique “core”, so its possible to rapidly unmount the module for the backup substitution.

Capabilities

CoreC is an FDM 3D printer designed for mid-scale production that operates within a real-time cloud system for production optimization. Main features:

- The management SW programs the machines to provide a targeted production of items by lowering the unsold while maintaining a high number of varieties.

- The software works interdependently with CoreC devices, arranged according to a decentralized model within strategic hubs inside the retail network.

- Modular system assembled into a server rack.

- The structure is designed to place from 1 up to 9 interchangeable 400x400mm printing plates, on a Z axis of 1800 mm.

- The printer provides sequential production, extruding on differents plates. Once a printing plate is completed, the printer unit controlled by the SW moves on to the next one, granting a continuous and flexible flow of production.

- The software communicates with the printer to provide a management plan that takes in account the needs of the market in real time and optimizes the printing plates with respect to the shape, time and size of the items to be produced.

- The modular system allows to choose the construction volume according to the production requirements.

Frame Material

The printer composed by two main elements:

- Server Rack: 19” rack contains the Z axis movement the power unit and hosts two CoreC modules: one core is functional and the other is for backup purpose

- CoreC module: Made of printed plastic and Aluminium 2020 extrusions.

Main innovations

This system allows to obtain several advantages:

Optimization of the printing process

- The system collects data on the sales and forecast and transforms them into organized printing plates, that are produced sequentially without any interruptions, thanks to the particular movement of the printing unit. When the machine is working at full capacity 24 hours a day, 7 days a week, the maintenance activities for a single machine are:

- Once a day: remove the complete plate and insert an empty plate.

- Once a week: change the coil.

- Once a month: replace the printing unit

Quick and easy maintenance

The particular structure of the printer reduces the manufacturing costs and the margin of error of the human factor. Characteristics are:

- 2 printing units in the rack, one is productive 24 hours a day / 7 days a week, the other is a backup.

- Once a month, the user must change the printing unit and send the used one to the service center, where it will be regenerated.

Optimization of the maintenance process

CoreC printer has a simple and rapid maintenance. When the machine works at full capacity, 24h, the maintenance activities for a single unit are:

- Withdraw the completed printing plate, reinsert the empty work plate (one/twice a day)

- Change the material (once a week if you use a 5Kg coil)

- Replace the printing unit with a new one and send it to the center for maintenance (once a month).

CoreC has been created with an open structure that makes interventions easier and faster, with a monthly maintenance, estimated in few hours of handiwork. It provides 20 Kg of plastic products per month for a machine unit.

Optimization of the space:

The printing unit operates in a compact server rack, designed to be transported and to durable. It assures a continuous printing cycle that makes each machine a competitive production unit.

Large build volume

The modular system allows to choose the construction volume according to the production requirements. The plate size is 400 x 400mm. Thanks to the interchangeable plates the height can be 100 mm up to 1,800 mm.

For the construction of larger objects it is possible to use the interlocking design, so that the individual pieces produced are subsequently assembled.

Electronics

Stepper Motors

The CoreC uses, including the extruder, four NEMA-17 stepper motors. Two of these motors control the X and Z positions in a Core XY configuration, one of them is reduced with a 5:1 platenary gear mechanism to control Z worm and the last controls the extrusion in a bowden configuration. The stepper motors needs a minimum holding torque of 40Ncm (0.4Nm).

Controller Electronics

The CoreC uses a DuetWifi controller board. This controller prevents step loss thanks to the TMC stepper drivers and grants a silent printing process.

Extruder

The extrusion system is composed by an E3D titan extruder and an E3D V6 1.75mm 24V Hotend in a bowden configuration.

Sensors

- Step loss sensor: integrated inside the TMC2660, detects motor currents and detects if the motor skips steps.

- Power sensor: detects any power loss and compensates with the UPS installed in the rack.

- Tachometer Fan: necessary to avoid damages to electronics or extrusion system caused by a stucked fan.

- IR bed level sensor: the infrared analog probe detects the plate during calibration to ensure a perfect level of the printer.

- Bed plate sensor: Can communicate to the user a bad plate position during the plate exchange process.

- Spool sensor: Detects the weight of the spool.

Software

It aims to ensure production that minimizes waste while maintaining a high level of product variety. To achieve the result, an ad hoc algorithm, algorithm 80/20, has been designed within the management SW. The implemented code is able to detect in a predictive way 20% of the references that will produce 80% of the sold and direct the production towards them. The "Ubique software" project consists in the construction of a software ecosystem, distributed in Cluod, Edge, Web and mobile environments, able to manage the production of 3D printed products responding to the sales of a network of stores. The software project therefore not only guides the sale of references identifying near real-time that 20% of references that will generate 80% of sales, but where also implement and partly automate the production process of the identified references, coordinate the different actors involved, monitor processes and react to events.