Clone wars: Ronquío

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

is under construction

Contents

Intro

- This printer is being constructed at and to University of Jaén and this is in the clone wars project

- Clon number XX

Mentions

Author

- José Antonio Pérez Caparrós

Record

|

|

|

Printed Parts

Full structure

| Picture | Piece (STL) | Quantity | Comments |

|---|---|---|---|

|

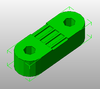

Bar Clamp | 8 | Original Bar Clamp |

|

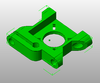

frame vertex with foot | 4 | original frame vertex with foot |

|

Frame vertex | 2 | Original Frame vertex |

|

Y motor bracket | 1 | Original Y motor bracket |

|

z motor mount | 1 | Z motor mount |

|

z motor mount | 1 | Z motor mount |

|

belt clamp | 2 | Belt clamp |

|

Belt clamp nut holder | 2 | Belt clamp nut holder |

|

Bearing guide | 3 | Bearing guide |

|

LM8UU Holder | 3 | LM8UU Holder |

|

jonaskuehling_x-ends_threadedrod_idler | 1 | Ends threadedrod idler |

|

ends_threadedrod_motor | 1 | Ends threadedrod motor |

|

x-carriage | 1 | X carrige |

|

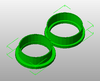

coupling | 2 | Coupling |

|

endstop-holder | 3 | Endstop-holder |

Extruder: Jonaskuehling

| Picture | Piece (STL) | Quantity | Comments |

|---|---|---|---|

|

jonaskuehling_gregs-wade-v3_jhead | 1 | Greg's Wade reloaded |

|

biggearmod_fixed | 1 | Big gear |

|

smallgearmod_fixed | 1 | Small gear |

Vitamins

In the area of self-replicating printers (repraps) are called vitamins to the parts that non-printable and you have buy them.

Vitamins for extruder

| Picture | Piece | Quantity | Comments |

|---|---|---|---|

|

M8 bolt | 1 | 1 to extruder |

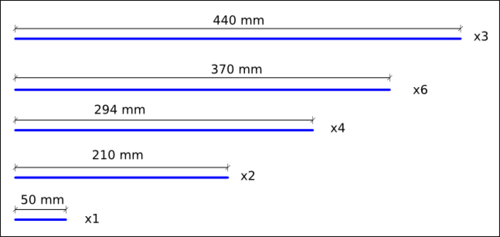

Threaded rods

In total needed 6 M8 threaded rods 1m long. It should be cut to the following sizes:

Smooth rods

|

We are needed 6 rods, of the following sizes:

|

Pictures

- Development

Videos

History

- 11/16/2012: Received printed parts set from multiXtruder

- 11/28/2012: Buyed nut, washer, bolt, grub screw, threaded rod, smooth rod, vinyl tubing, bouncy, clamps, terminals, power supply Tooq 500W, etc..

- 11/03/2012: Received RAPMS 1.4 wiht Clon Mega2560, LCD 20x4, Keypad v1.0, Thermistor 100K, 2x Axial Fan 50x50x12mm 12V, 2m PTFE tubing and Pneufit straight adaptor from Reprapworld.

- 11/05/2012: Received 4x Allegro 4982 with heatsink, Thermistor, Heat Bed MK2, 3x Endstops, 5x Nema17, Jhead Mk V-B, wires, 2x pulleys, 2m timing belts, bearing 608zz and LM8UU, hobbed bolt Hyena, 2x ABS 1kg and PLA 1kg from LEAPto3d.

- 12/07/2012: Received kapton tape from Incopia2.

- 12/08/2012: Rods cut and revise plastic pieces.

- 12/13/2012: Solder Allegro 4982 and embedded nuts.

- 12/18/2012: Assembly basic structure, it absence axis X

Links

| Proyecto Clone Wars |