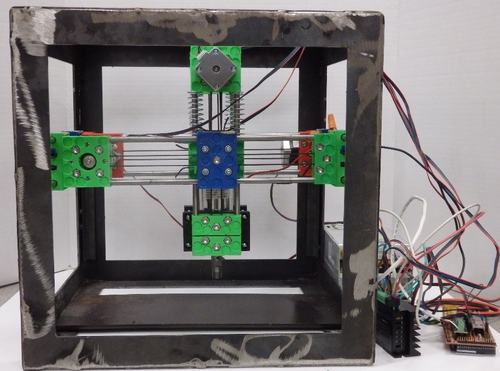

Belt-Driven Open Source Circuit Mill Using Low-Cost 3-D Printer Components

|

By Michigan Tech's Open Sustainability Technology Lab.

Wanted: Students to make a distributed future with solar-powered open-source RepRap 3-D printing and recyclebot recycling. |

|

Template:Pearce-pubs

Source

- Oberloier, S. and Pearce, J.M. Belt-Driven Open Source Circuit Mill Using Low-Cost 3-D Printer Components, Inventions 2018, 3(3), 64; https://doi.org/10.3390/inventions3030064 open access

- bill of materials (BOM) available at https://osf.io/mf78v/

Abstract

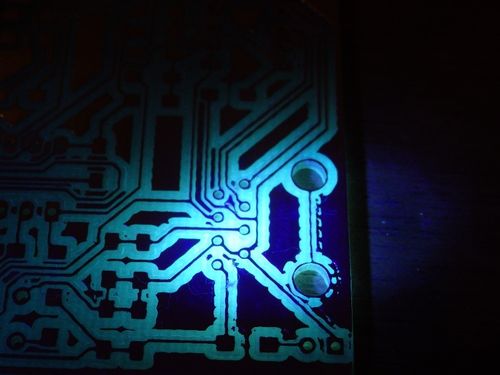

Barriers to inventing electronic devices involve challenges of iterating electronic designs due to long lead times for professional circuit board milling or high costs of commercial milling machines. To overcome these barriers, this study provides open source (OS) designs for a low-cost circuit milling machine. First, design modifications for mechanical and electrical subsystems of the OS Distributed 3-D (D3D) Robotics prototyping system are provided. Next, Copper Carve, an OS custom graphical user interface, is developed to enable circuit board milling by implementing backlash and substrate distortion compensation. The performance of the OS D3D circuit mill is then quantified and validated for: positional accuracy, cut quality, feature accuracy, and distortion compensation. Finally, the return on investment is calculated for inventors using it. The results show by properly compensating for motion inaccuracies with Copper Carve, the machine achieves a motion resolution of 10 microns, which is more than adequate for most circuit designs. The mill is at least five times less expensive than all commercial alternatives and the material costs of the D3D mill are repaid from fabricating 20–43 boards. The results show that the OS circuit mill is of high-enough quality to enable rapid invention and distributed manufacturing of complex products containing custom electronics.

Template:Statusboxtop Template:Status-baseTemplate:Status-model Template:Status-prototype Template:Status-verified You can help Appropedia by contributing to the next step in this OSAT's status. Template:Boxbottom

Keywords

open source hardware; open hardware; RepRap; 3D printing; OpenSCAD; customization; open science hardware; OScH; free and open-source hardware; FOSH; free and open-source software; custom designs; distributed manufacturing; P2P; P2P manufacturing; open design; scientific equipment; open scientific hardware; 3-D printing; circuit milling; circuit design; distributed manufacturing; electronics; electronics prototyping

See Also

- General Design Procedure for Free and Open-Source Hardware for Scientific Equipment

- Open Source Lab

- Building research equipment with free, open-source hardware

- Open source science

- Open-source hardware