Category:Wilson

Release status: working

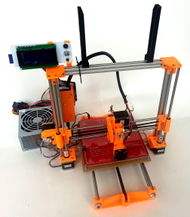

| Description | A reprap built with Aluminum Extrusions for framing.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Reprap Wilson is a descendant of the Prusa i3 style reprap. It also has elements similar to the Lulzbot Taz (particularly the Wilson II).

The main goal of Wilson was to replace the frame with one built from standard Aluminum extrusions (2020). Additionally, the design has a parametric build area, meaning it is relatively easy to scale the X, Y, and Z axis within reason. I've also made an effort to reduce the number of unique parts used as much as possible, and incorporated some other design ideas that I have tried on the Prusa i3 previously (monolithic Y ends, easy adjustment of the Z limit switch, integrated endstop holders, among others).

The standard BOM is for a 200mm³ build area (Wilson TS) and 200x300x200 (Wilson II).

Source files for Wilson can be found on github: http://github.com/mjrice/wilson

A community forum for the Wilson design is hosted here: community.reprapwilson3d.com

Build Variants

There are three versions of the reprap Wilson design, the newer Wilson II and two predecessors designated as the R and T Series, or simply RS and TS.

Wilson II

In comparison to the original Wilson design, the changes with Wilson II are:

|

|

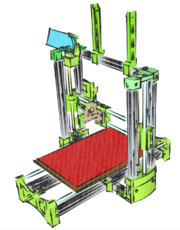

Wilson RS

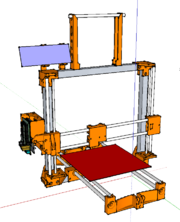

Wilson TS

Pages in category "Wilson"

The following 4 pages are in this category, out of 4 total.

Media in category "Wilson"

The following 20 files are in this category, out of 20 total.

- Wilson-duct.jpg 1,000 × 750; 130 KB

- Wilson-extruder.jpg 1,000 × 750; 162 KB

- Wilson-filament-brackets.jpg 1,000 × 579; 166 KB

- Wilson-frame-rearbracket-ts.jpg 1,000 × 750; 187 KB

- Wilson-frame-rearbracket.jpg 1,000 × 990; 202 KB

- Wilson-gears.jpg 1,000 × 750; 181 KB

- Wilson-ramps-mount.jpg 1,000 × 750; 173 KB

- Wilson-rs.png 671 × 827; 60 KB

- Wilson-ts-photo.jpg 2,236 × 2,368; 1.58 MB

- Wilson-ts.png 928 × 862; 150 KB

- Wilson-x-idler.jpg 1,000 × 750; 153 KB

- Wilson-x-motor.jpg 1,000 × 750; 170 KB

- Wilson-xcarriage.jpg 1,000 × 750; 158 KB

- Wilson-y-bearing-holder.jpg 1,000 × 751; 191 KB

- Wilson-y-idler-ts.jpg 1,000 × 697; 192 KB

- Wilson-y-idler.jpg 1,000 × 594; 136 KB

- Wilson-y-motor-ts.jpg 1,000 × 668; 188 KB

- Wilson-y-motor.jpg 1,000 × 627; 153 KB

- Wilson-z-motor.jpg 1,000 × 750; 163 KB

- Wilson-z-rodholder.jpg 1,000 × 750; 210 KB