Web4Deb extruder

Introduction

The Web4Deb Extruder is a functional auger based granular extruder that produces perforated HDPE strips for use in aquaponics. A video of the extruder in action can be found [here]. The blog of the creator (Web4Deb) can be found [here].

Specifications

- The barrel is heated with a length of Nichrome wire and and insulated with what appears to be polyimide tape.

- The auger is a standard 3/4" wood auger bit (bought a set from Harbor Freight) and cut it down to length.

- The auger is driven by a wind shield wiper motor which is geared down with a bicycle chain and sprocket.

- The heating element draws around 16A at 12V (192W) from a computer power supply.

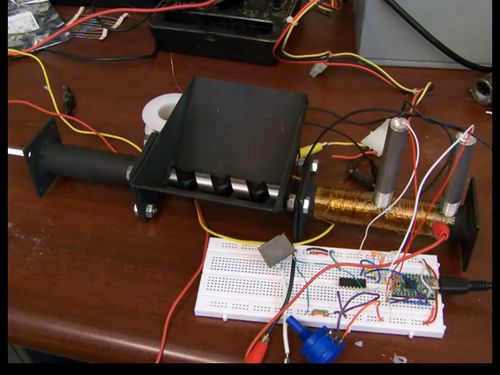

- The temperature for the extruder barrel is controlled with a Teensy AVR micro-controller.

- The die appears to be interchangeable.

- The extruded HDPE is forced through a set of fan cooled rollers.

- Two individual temperature sensors are located on the extrusion barrel.

- The Teensy AVR micro-controller appears to be used to switch one or more relays through a transistor array.

Questions

- How far does the auger drill bit extend into the extruder barrel?

Answer: The auger bit is a standard 3/4" wood auger bit. The bit is cut to a length that allows the bit to enter the barrel and stop just short of the first temp. sensor. This is necessary because the temp. sensor extends into the barrel slightly and would come in contact with the auger bit were it not shortened.

- what is the RPM of the auger while extruding?

- What type of thermistor is used for the temperature sensing?

Answer: Resistance Temperature Detectors (RTDs)are used and potted into a 1/4" NPT pipe.

- Is it really required that the temperature be measured in two places?

Answer: Two individually controlled temperature zones. The first one is supposed to have a temperature lower than the second one. Two stage heating of thermoplastic beads to melt gradually as they are pushed through the barrel and lowers the risk of overheating which may cause degradation in the polymer. Information Source

- Is there two separate windings of nichrome wire that are individually controllable?

- What RPM is are the pinch wheels running at?

- How are the pinch wheels powered?

Further information

There are 3 sections 1) bearing chamber, hopper, and heating chamber. These are made with a section of ¾” black pipe (gas pipe) and ¾” wood auger bit fits nicely into the pipe. There is a little bit of gap between the auger and pipe which I was concerned the molten plastic would ooze back out of, but it was never a problem. This unit can consume virgin HDPE pellets or cut up milk bottles.

The bearing chamber is about 3.5” long and is mostly dead space. The shaft of the auger bit is long and I didn’t feel like turning it down shorter. At the end where the shaft comes out, there is a thrust bearing placed on it to minimize the friction.

The hopper has half of the black pipe cut away to expose the auger. This is 4.5” long and has a metal hopper which holds around 1 cup of pellets. As the auger turns some pellets get forced into the heating chamber while some just sort of move to the front of the hopper. Between the hopper and heating chamber is ¼” of plywood…to act as a heat insulator to minimize the heat loss through the metal.

The heating chamber has two heating zones. The main reason was to attempt to heat the plastic evenly since I wasn’t sure how it would heat as it moved through the chamber. This chamber is 5 inches long. The first temperature sensor is placed about half way through and the auger bit ends just before it (so it won’t hit against the probe). The second reason was I didn’t want to run a high voltage through the Nickel Chromium wire…too dangerous and I had a couple of PC power supplies I could run 12 volts at 8 amps. The pipe is wrapped in Kapton tape which is heat resistant….but you can see in the photo it did eventually burn through. Each zone is independently controlled by a microprocessor to maintain a consistent temp.

The heating chamber has a flange on the end which allows different die plates to be bolted on to the end. Depending on the size of the “hole” in the die, the plastic will extrude at different speeds. For the 1/4” slot, the auger turns at about 18rpm and can produce a ribbon of material at roughly 200 feet/hour.

As the molten plastic is extruded out of the die, it is fed through two pinch wheels that are held together in a lego contraption. This system is independent of the extruder and is driven with a standard Lego motor and geared down to run at the same speed as the extrusion. As the plastic passes through the rollers, it quickly cools and gets a texture applied to it. There is a tube at the exit where air is blown against the plastic and rollers to keep them cool, otherwise the plastic will stick to the rollers.