Eiffel

Release status: Concept

| Description | a powder printer with a stationary bed and mobile gantry

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Note: Eiffel works great but is poorly documented. --Sebastien Bailard 18:08, 30 July 2010 (UTC)

Introduction

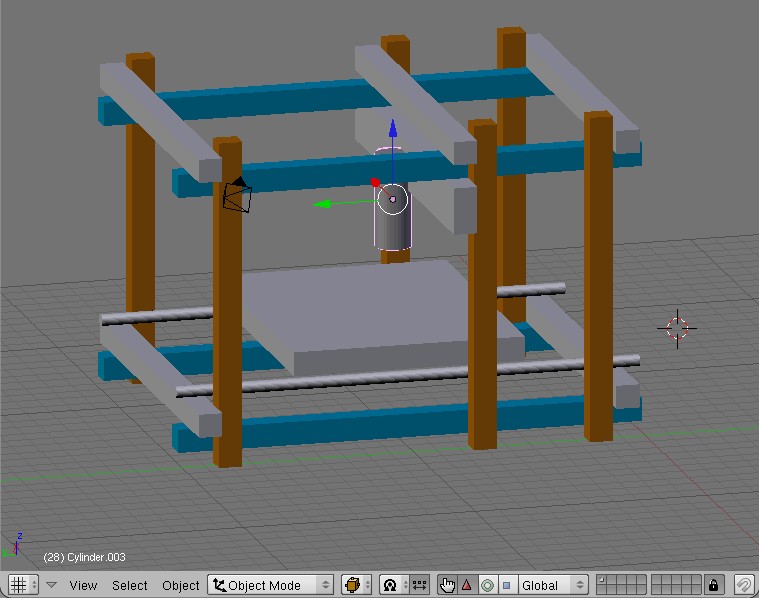

Eiffel is a proposal for a post-Mendel RepRap, which will function as a 3D printer, and as a CNC_Router.

The first version will have a footprint of ~1 ft x 2 ft (30 cm x 60 cm), and a workspace of 8.5 inch x 11 inch x 4 inch, or 20 cm x 30 cm x 10 cm.

Eiffel is made from a number of square beams bolted toghether in TriLap joints. These square beams are either steel tube, aluminum tube, or solid wood, depending on availability and user preference. The beams are drilled for bolting together in tri-joints. If convenient, these beams are drilled with regularly spaced through-holes along each long side. (See RBS).

We aim to supersede Mendel by being able to engrave and drill pcbs, and also machine wood and non-ferrous metals. Eiffel will also be useful for hybrid fabrication. This is essential for making Gears.

Machine Requirements (preliminary)

(I think we need to pin down our machine requirements. Right now I'm thinking 'good 3D printer', 'decent CNC router for drilling PCBs and routing basswood+, 'decent powder printer'.)

The 'decent powder printer' would be innovative, but we need to overbuild the frame in order to eventually CNC cut aluminum and other non-ferrous, and _ideally_ through-hole steel.

Development Pathway

The first working model will have a workspace about the same as letter-sized paper. 8.5" x 11" x 4" (22 cm x 28 cm x 10 cm)

Our target work volume is 24" x 48" x 8".

We will try to extend this use of Gridbeam and Erector-set like technology into a RepRap_Building_System or RBS system that leverages RepRap to make lots of mechatronic systems using grid beam and grid sheet, and 3D printed gears, etc., but that's sort of beyond the initial scope of this project. (Step 2, technically)

Files/Modeling

Eiffel is still in preliminary development. We currently have the 'napkin-sketch' above, a Blender file or two (available tomorrow), and a number of graph paper sketches.

Please use your favorite modeling program or CAD program and join in!

Community

Eiffel is a RepRap project; We're using the RepRap forum: and the associated RepRap mailing list:

Parts

Imperial or Metric

The Eiffel-I version uses imperial-sized parts. Eiffel-M uses metric-sized parts.

When it matters, please be careful to indicate which version you're using and modifying.

Structure

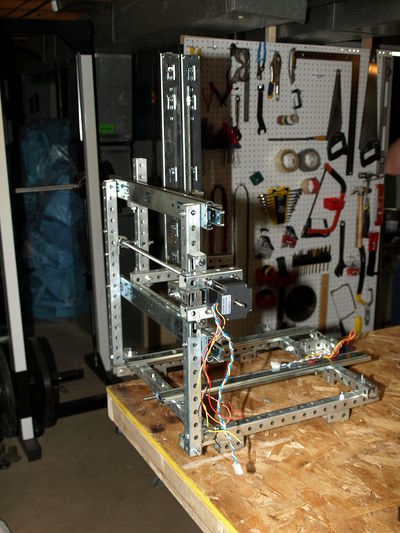

Beam

1x1 inch, cost ~$22 per 6ft piece.

The preliminary concept sketch seems to show (very roughly) about 32 feet of beam, requiring 6 of these 6 ft pieces.

The photos seem to show (very roughly) about 16 feet of beam, requiring 3 of those 6 ft pieces -- is that really all that is required, or were those photos taken halfway through construction?

square steel tubing or square wood beams.

If possible, these are perforated and otherwise shaped using the mom-Eiffel, or a handy drill press.

Lots of PegBoard

See LeCorb.

Rails

Highly variable.

Drawer slides are easy to prototype with. Real steel rod for when we're serious.

Motion Control

rotary to linear motion conversion:

Undecided: Toothed Belt, Threaded Rod, or Rack and Pinion

Cross-Connectors, Fasteners

3D printed by the 'Mom' Eiffel or RepRap, or made by cnc router, or laser cutter. Huh? Once you put the 3 bolts through the tri-lap joint, and tighten the nut against the washers, what other connector or fastener do you need?

Material

- Thermoplastic or

- Filled_Epoxy (Using a CNC router and a 3D printer to make the molds

for the fittings, and then using the molds to cast fittings from filled epoxy.)

Spindel

- Taig Spindle

or http://www.engravingmachine.com/html/router_spindles.html e.g. http://www.engravingmachine.com/html/router_spindles_-_kress.html

Applications

- Drilling steel or aluminum beams for daughter-Eiffels. (We may have to set up in a CNC_Mill configuration to drill steel.

- PCB routing

- Hobby-scale Robot parts (CNC-routed and 3D printed)

User wants and needs: Journeyman (just graduated) architecture student, who will need CNC router/3D printer for modelmaking and crafting.

Also: FabLabs, RepRap users, hobbyists (RC plane folk cut a lot of balsa on medium scale CNC routers) and educators.

Design Philosophy

The RepRap project has successfully made a 3D printer using the GPL for a license. Eiffel will do the same, and will leverage and contribute to RepRap technology and community. We will use the GPL and the RepRap website to be able to freely interoperate with standard RepRap hardware and software.

There is no mature and well-publicized GPL CNC router. Eiffel will fill that space, along with being a CNC-router.

Working Notes

Everything below here is poorly organized. Sorry.

Capabilities

- Work volume of 24" x 48" x 8".

- Wood cutting - ~100% duty cycle.

- Metal cutting - light aluminum and other non-ferrous cutting.

- Steel - drilling.

- 3D printing:

1) Thermoplastic: like a normal RepRap

2) Powder Printer: Preliminary discussion. http://dev.forums.reprap.org/read.php?1,31168,31181

Fabrication/Tooling

To make an eiffel from square tubing or beam, drilled for bolting together in tri-joints. It will _not_ require a normal machine shop.

Saw

Drill Press

???

Maybe benchtop CNC mill for fittings, but would greatly prefer having mother Eiffel or other cnc router, 3D printer make fittings from Filled_Epoxy.

Self-replication

Does it drill holes in the beams of it's daughter machines? You can.

But for the first one, it's much much faster to source pre-drilled square steel beams. McMaster-Carr down in the US has it, and local construction suppliers _everywhere_ should be able source it given 2 months forewarning. http://www.mcmaster.com/#steel-structural-tubing/=49tu63

Once you've got a machine, it's really easy to make lots of wood grid beam. And maybe you can drill holes in steel with it. It would be convenient, and a useful target benchmark. It would be hard to make this as good as a Taig Mill, but fun to try.

normal CNC routing

How do we generate G-Code from for cutting the outsides of stuff. You know, 80% of normal CNC routing?

Perhaps use one of the "2D" packages listed at Useful Software Packages, and if it doesn't directly produce G-code, use something like Builders/Replath to convert from SVG or DXF to G-code?

Chatter

We need to turn this into a machine with a stationary bed and mobile gantry if we're to extend it into use as a powder printer. This is conceptually straightforward, if we can do a dropping bed and borrow candyfab's or someone else's powder mechanisms.