Previous versions

The build manual for the previous versions are here :

- The page here will be updated for the version 3.5 someday

Tools

Needed tools

Bonus tools

General tips

- Read the whole manual before starting to get an overview of the building steps (total: 12 hours of assembly).

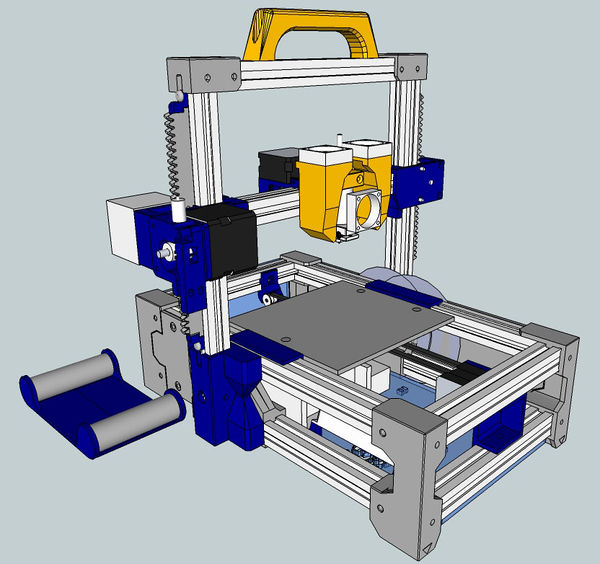

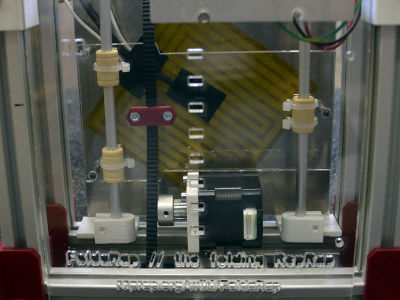

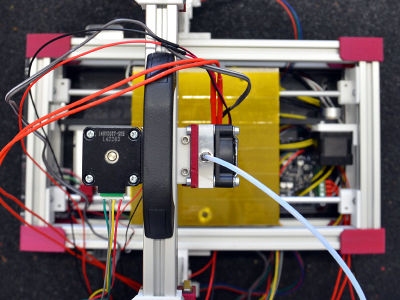

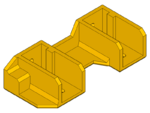

- The FoldaRap is made of a base frame and several sub-assemblies. Some can be done in parallel to save time, gather your friends and establish a new building time record !

- Work on a cutting mat if you have one: it will protect your table plus they often show a millimetre grid that can be useful to check the bolts length (with experience you will recognize them by looking or holding one).

- Place your mouse over a picture to know the element name.

- Do not hesitate to have a look at the 3D model in SketchUp (before/during the build): it will show you the folded/unfolded state of the machine and you can play around with it.

Printed parts

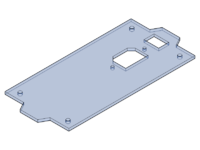

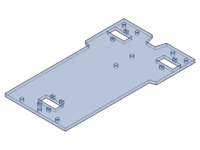

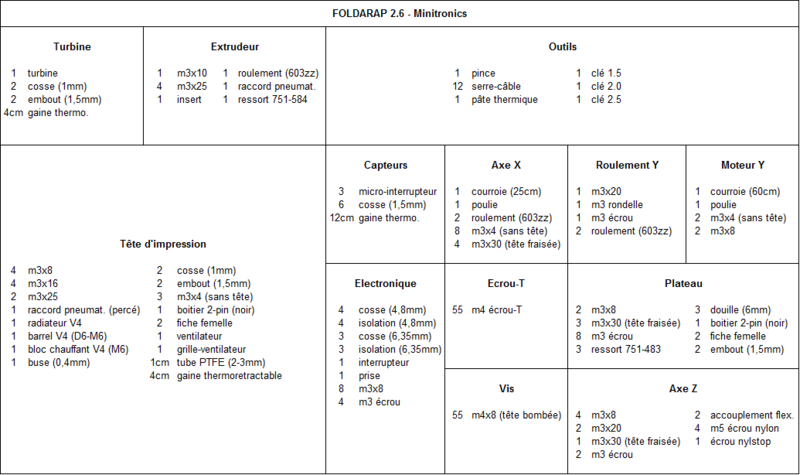

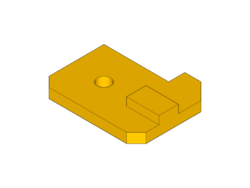

Lasercut parts

Screws & bolts box

The screws and bolts are arranged in their box according to the assembly steps to simplify their identification.

Use environment

- Dry environment

- Room temperature (between 5°C and 35°C)

- Protected from dust

- On flat surfaces

- Protected from inflammable substances

- Apart from other electronic devices

A use out of these conditions can damage your 3D-printer...

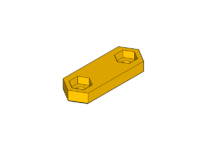

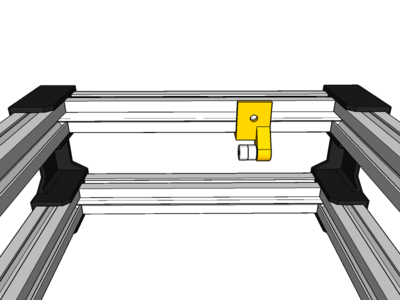

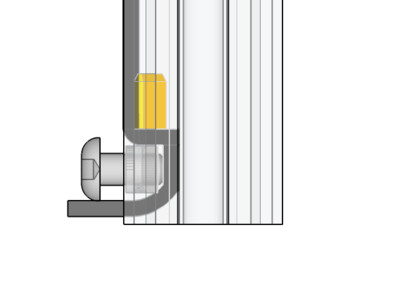

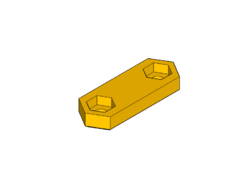

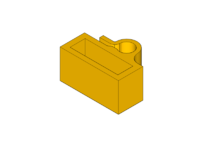

Insert a T-nut

tightening torque: 2.5 N.m (+/- 5%): use the small side of the 2.5 hexagonal wrench to get the ideal torque

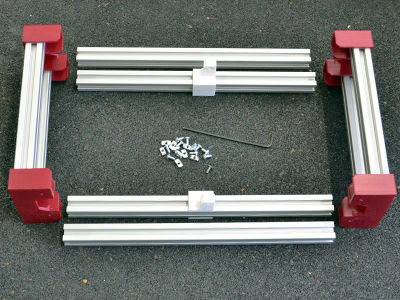

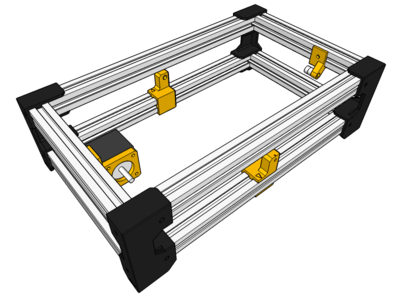

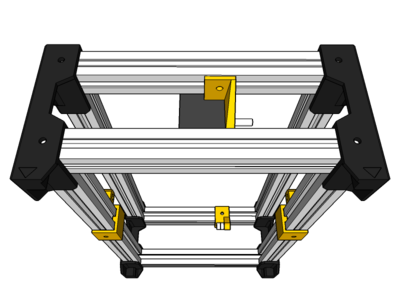

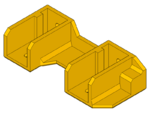

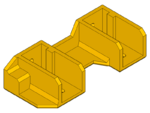

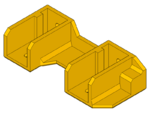

Step 1/20 - Base Frame (30 min)

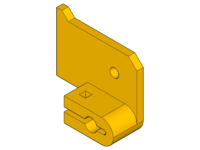

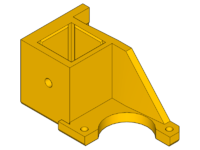

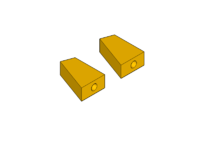

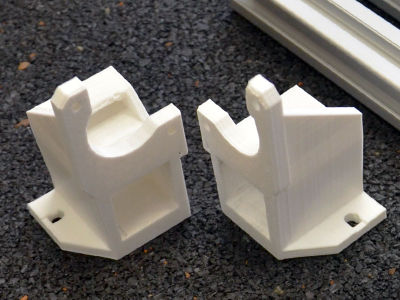

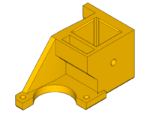

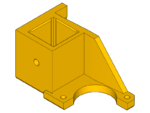

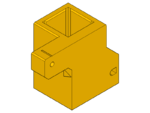

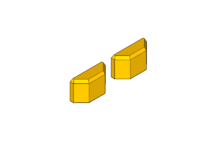

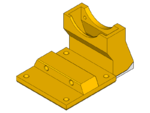

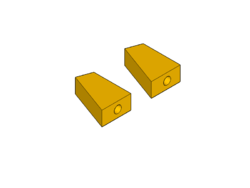

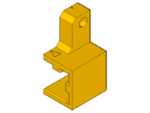

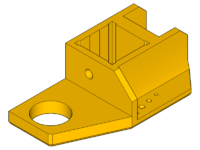

x1 foot front left

x1 foot front left

x1 foot front right

x1 foot front right

x2 200mm profile

x2 200mm profile

x4 M4x8

x4 M4x8

x4 T-nut

x4 T-nut

position the aluminium profiles in the front feet...

... and push them completely so that there is no more space between the metal parts and the printed parts

position the T-nuts in the groove of the aluminium profiles and push them under the holes with the 2.5 hexagonal wrench

screw the M4x8 in the T-nuts through the printed parts with the 2.5 hexagonal wrench: make sure that the T-nuts turn 90° and grab the aluminium profiles

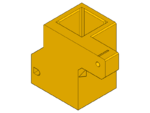

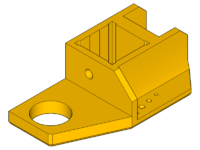

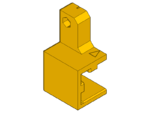

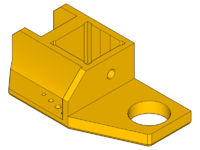

x1 foot rear right

x1 foot rear right

x1 foot rear left

x1 foot rear left

x2 200mm profile

x2 200mm profile

x4 M4x8

x4 M4x8

x4 T-nut

x4 T-nut

start again with the rear feet

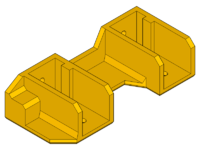

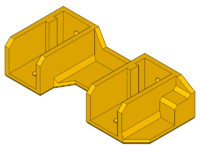

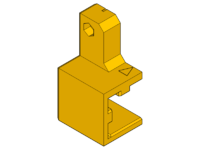

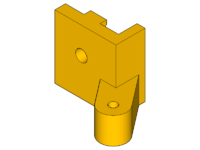

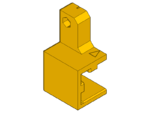

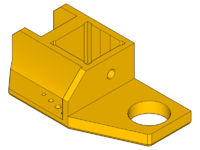

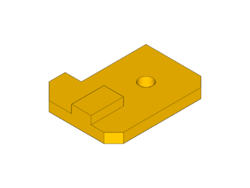

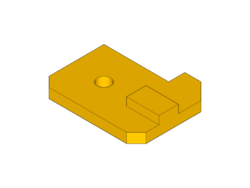

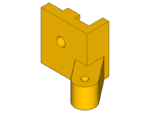

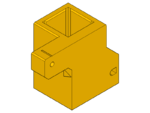

x1 hinge inner left

x1 hinge inner left

x1 hinge inner right

x1 hinge inner right

x4 300mm profile

x4 300mm profile

x10 M4x8

x10 M4x8

x10 T-nut

x10 T-nut

position the inner hinges in the middle of the lower 300mm aluminum profiles (printed part oriented inside the machine) and lock them with T-nuts and M4x8

finish the base frame by locking the 300mm profiles in the feet with the T-nuts and M4x8 (make sure that their is no space between the 200mm and the 300mm profiles)

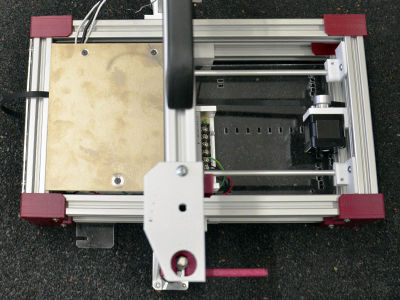

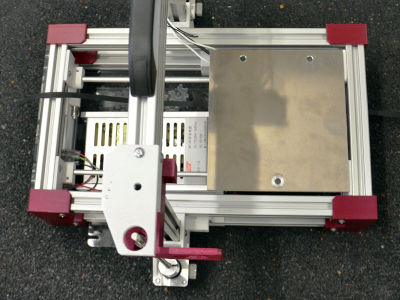

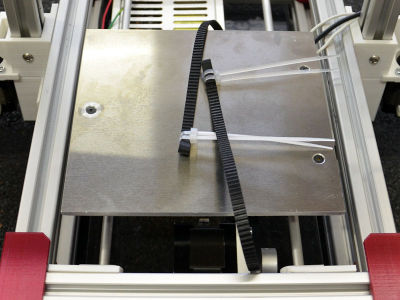

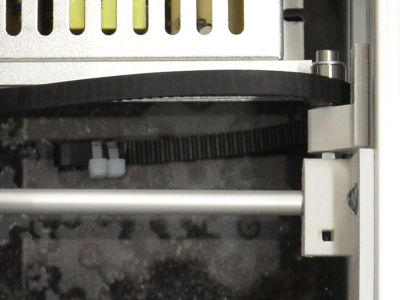

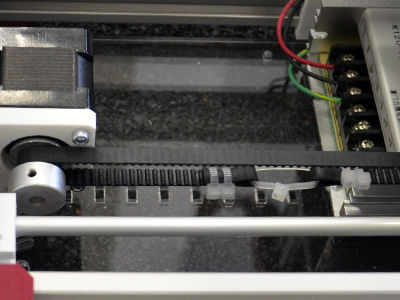

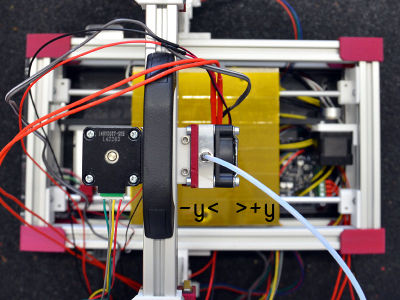

Step 2/20 - Y-axis (30 min)

Y-idler

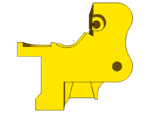

x1 y-idler

x1 y-idler

x1 M4x8

x1 M4x8

x1 T-nut

x1 T-nut

x1 M3x20

x1 M3x20

x1 M3 washer

x1 M3 washer

x2 603zz bearing

x2 603zz bearing

x1 M3 nut

x1 M3 nut

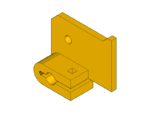

position the T-nut and the M4x8 on the y-idler without tightening

place the M3 nut in the y-idler imprint

pass the M3x20 through the M3 washer and the bearings...

... and screw it in the M3 nut

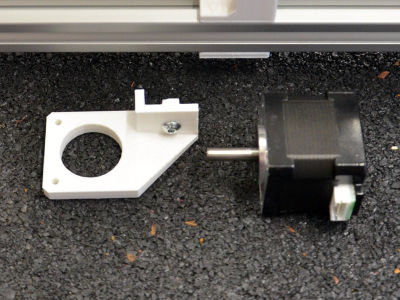

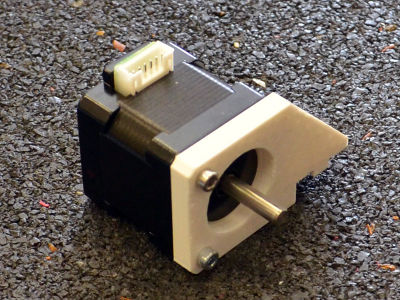

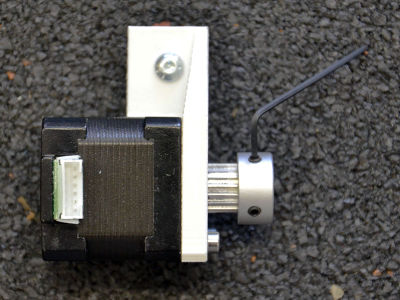

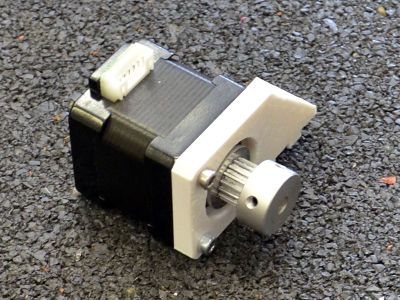

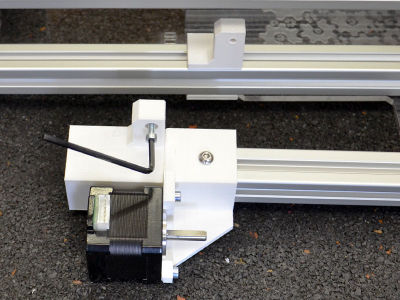

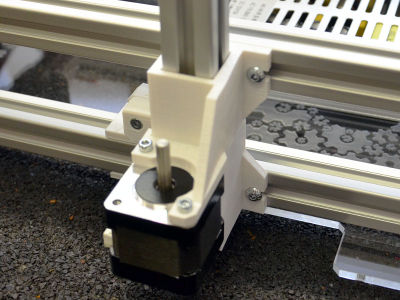

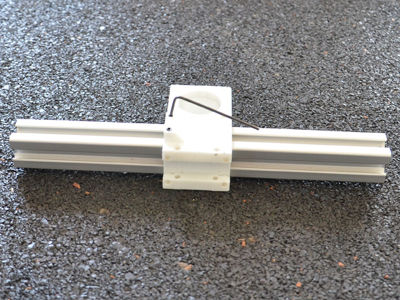

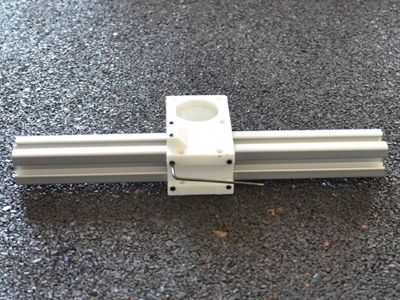

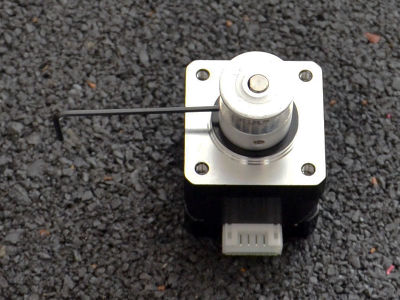

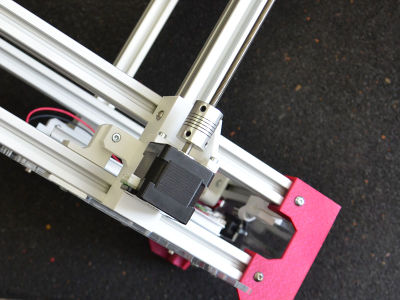

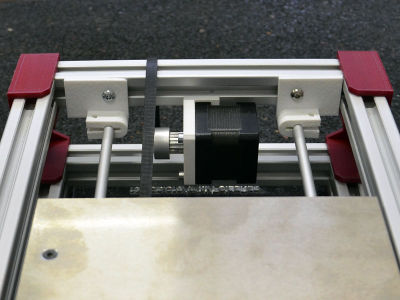

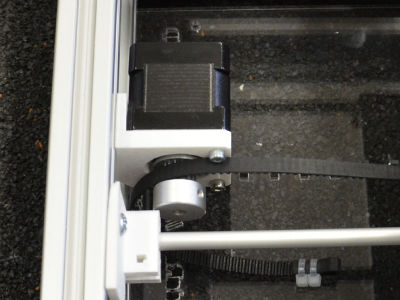

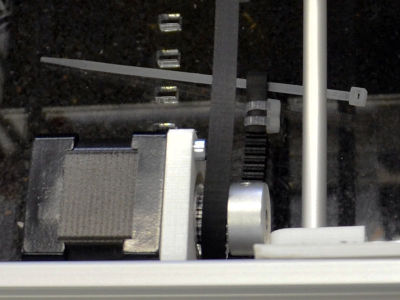

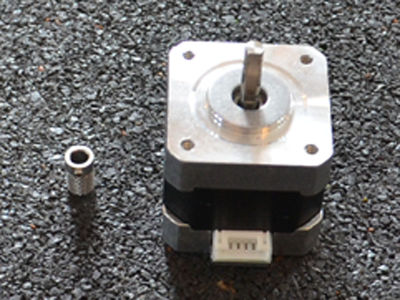

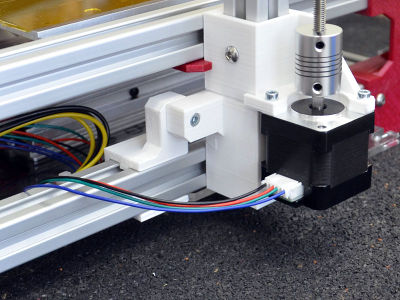

Y-motor

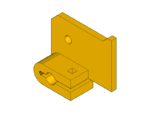

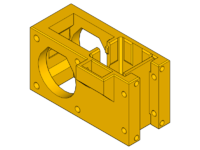

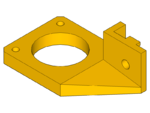

x1 y-motor

x1 y-motor

x1 M4x8

x1 M4x8

x1 T-nut

x1 T-nut

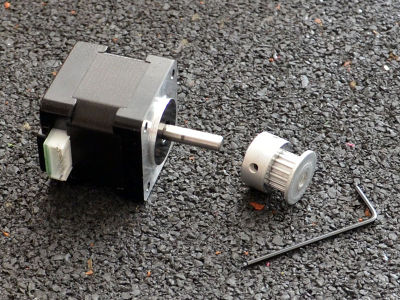

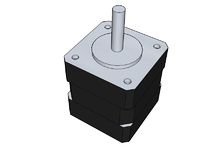

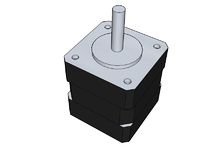

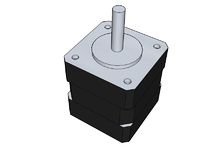

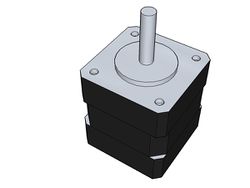

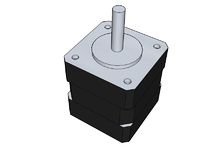

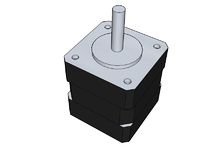

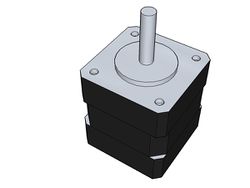

x1 nema 14

x1 nema 14

x2 M3x8

x2 M3x8

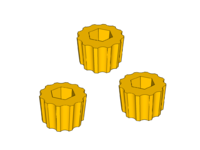

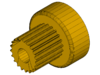

x1 pulley

x1 pulley

x2 grub screw

x2 grub screw

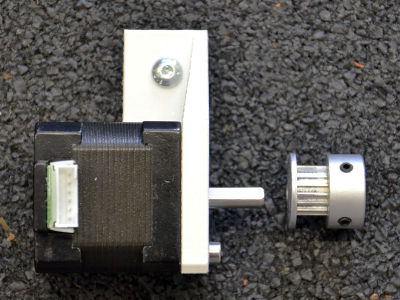

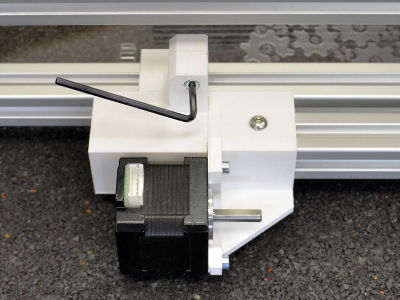

position the T-nut and the M4x8 on the y-motor without tightening

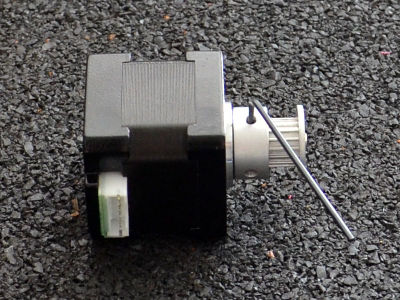

fix the motor on the printed part with the M3x8 (be careful with the connector orientation)

insert the grib screws in the pulley with the 1.5 hexagonal wrench

position the pulley on the motor shaft

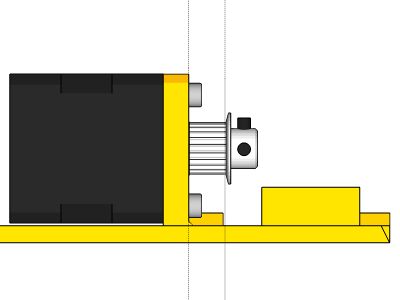

make sure that the flange is aligned with the printed part...

... and lock the pulley...

... with one grub screw on the flat part of the shaft

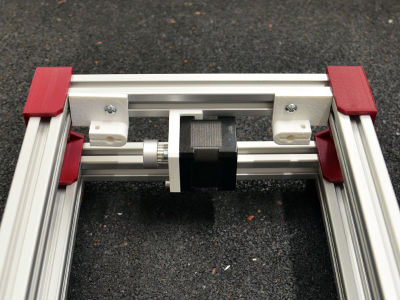

Y-idler & motor

position the y-idler (without locking it) the same side as the higher part of the inner hinges and the y-motor (without locking it) on the opposite side

the screw is oriented downward for the y-motor...

... and from the inside for the y-idler

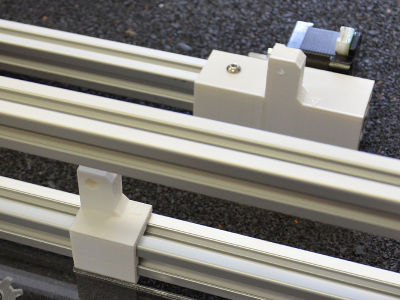

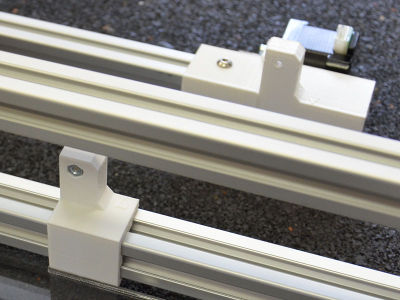

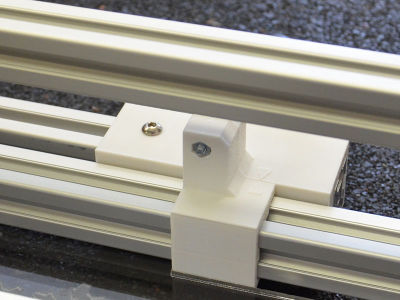

Rod-idler

x4 rod-idler

x4 rod-idler

x4 M4x8

x4 M4x8

x4 T-nut

x4 T-nut

position the T-nuts and the M4x8 on the printed parts without tightening

position the rod-idlers on both sides of the y-idler and against the aluminum profile and tighten; push the y-idler against the rod-idler and lock it on the aluminum profile

position the rod-idlers on both sides of the y-motor and against the aluminum profile and tighten

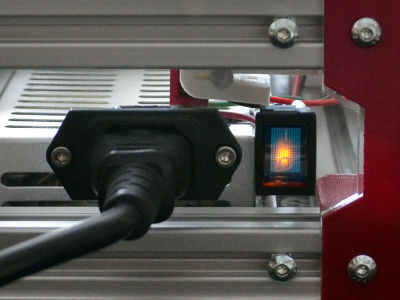

Step 3/20 - Plug + switch (45 min)

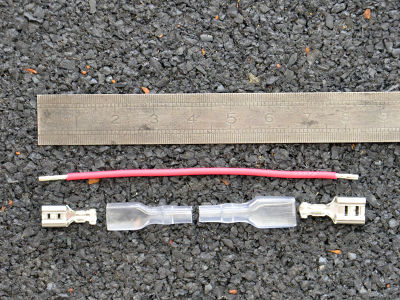

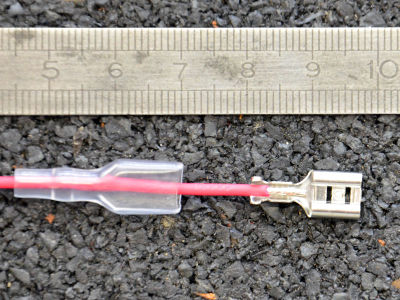

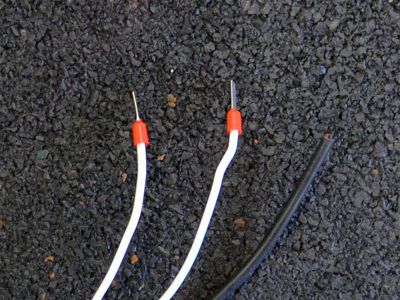

Cable 1

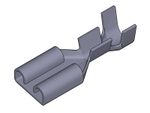

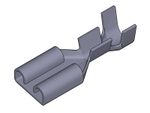

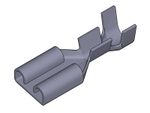

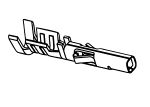

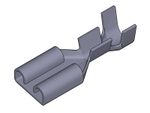

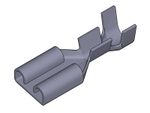

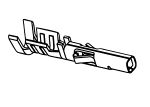

x1 4,8mm ferrule (+ insulation)

x1 4,8mm ferrule (+ insulation)

x1 6,35mm ferrule (+ insulation)

x1 6,35mm ferrule (+ insulation)

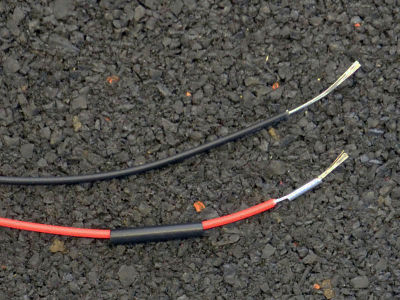

cut a 10 cm red wire and strip the extremities

don't forget to place the insulations before the ferrules (pay attention to the insulations size)

crimp firmly a 4,8 mm ferrule on one side and a 6,35mm ferrule on the other side

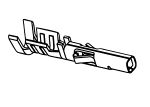

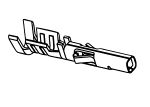

to crimp a ferrule on a cable: press 2 strips on the cable's insulation and press 2 strips on the cable's metal wires

bring the insulations over the ferrules

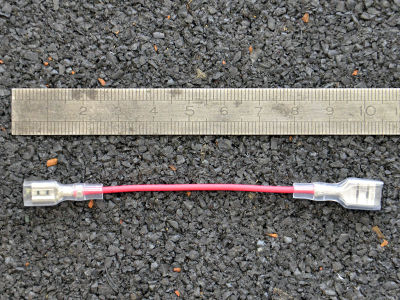

Cable 2

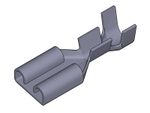

x1 4,8mm ferrule (+ insulation)

x1 4,8mm ferrule (+ insulation)

x1 6,35mm ferrule (+ insulation)

x1 6,35mm ferrule (+ insulation)

cut a 10 cm black wire and strip the extremities

crimp firmly a 4,8mm ferrule on one side and a 6,35mm ferrule on the other side

bring the insulations over the ferrules

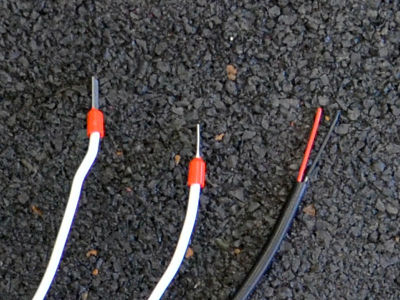

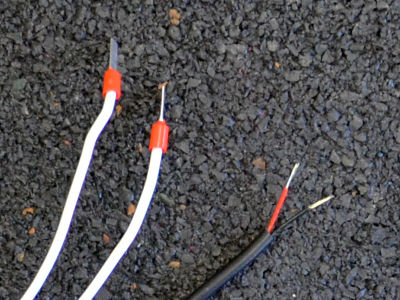

Cable 3

x1 4,8mm ferrule (+ insulation)

x1 4,8mm ferrule (+ insulation)

take the 25 cm black wire and strip the extremities

crimp firmly a 4,8mm ferrule on one side and bring the insulation over the ferrule

Cable 4

x1 4,8mm ferrule (+ insulation)

x1 4,8mm ferrule (+ insulation)

take the 25 cm red wire and strip the extremities

crimp firmly a 4,8mm ferrule on one side and bring the insulation over the ferrule

Cable 5

x1 6,35mm ferrule (+ insulation)

x1 6,35mm ferrule (+ insulation)

take the 25 cm green wire and strip the extremities

crimp firmly a 6,35mm ferrule on one side and bring the insulation over the ferrule

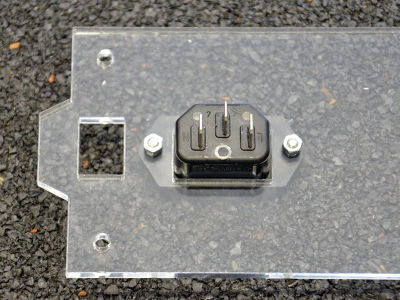

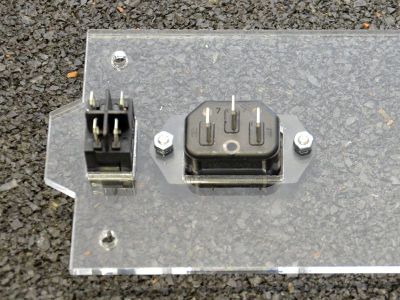

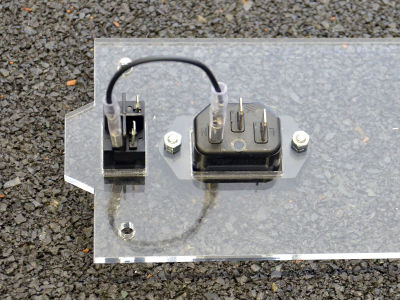

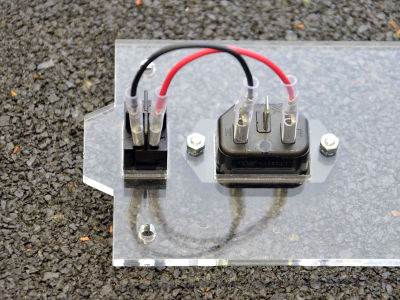

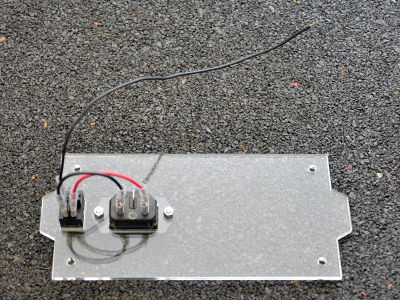

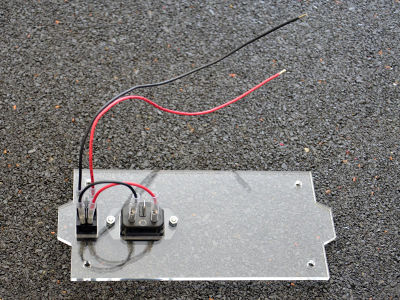

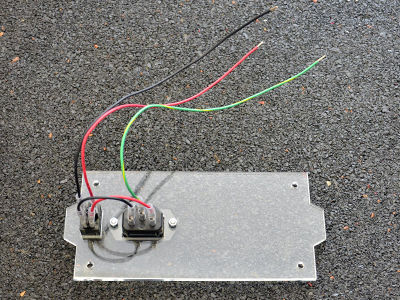

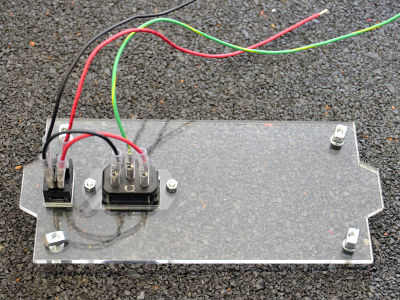

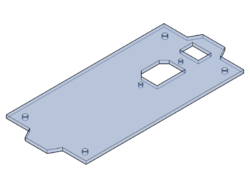

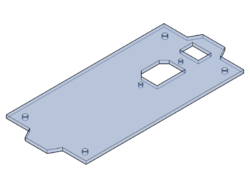

Plug-plate

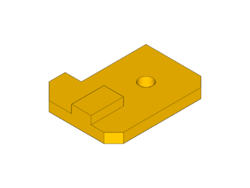

x1 plug-plate

x1 plug-plate

x1 plug

x1 plug

x1 switch

x1 switch

x2 M3x8

x2 M3x8

x2 M3 nut

x2 M3 nut

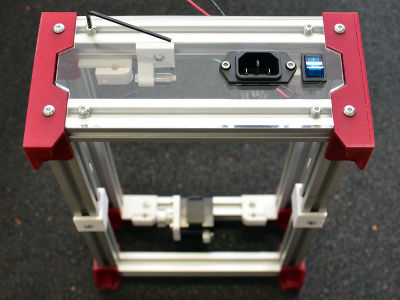

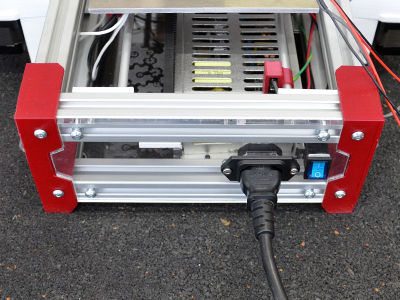

push the switch completely through the plug-panel ("O" position oriented downward)

x4 M4x8

x4 M4x8

x4 T-nut

x4 T-nut

fix the plug-panel the same side as the y-idler

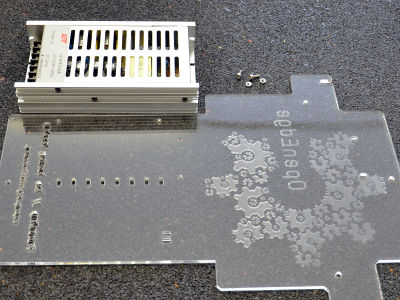

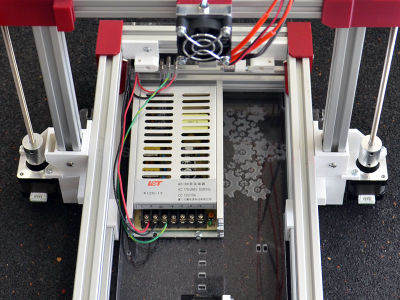

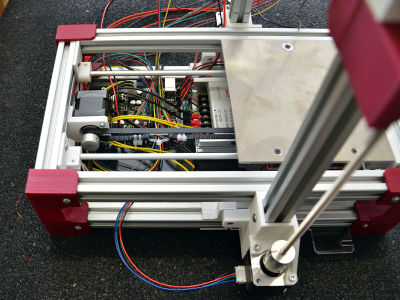

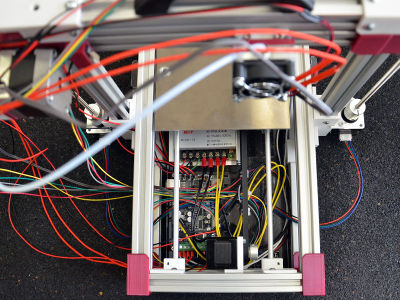

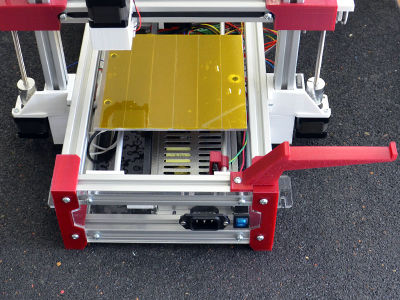

Step 4/20 - Underplate (20 min)

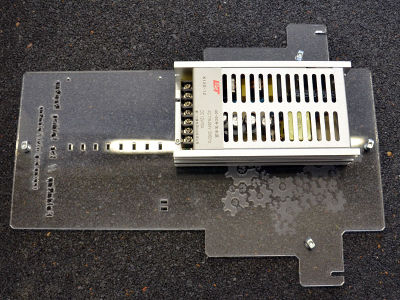

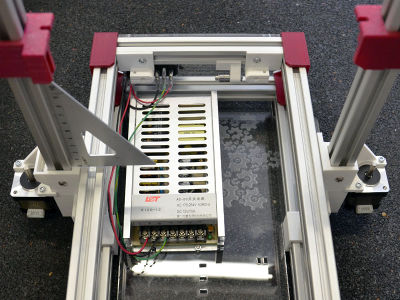

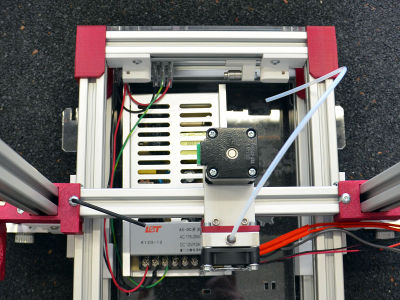

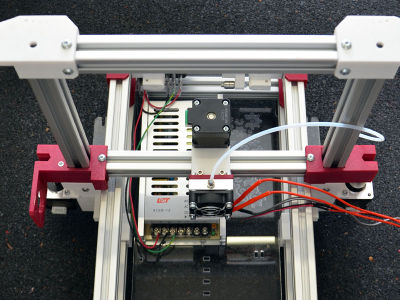

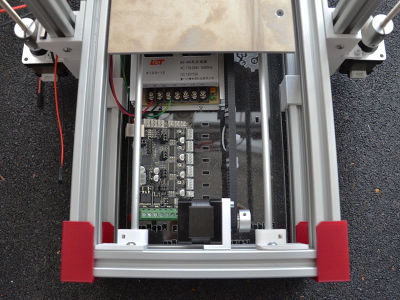

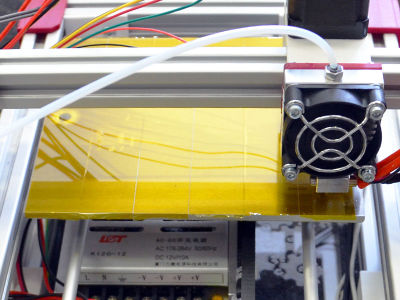

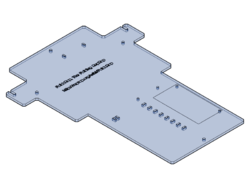

Power supply fixing

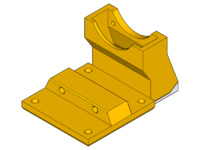

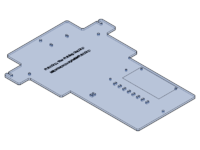

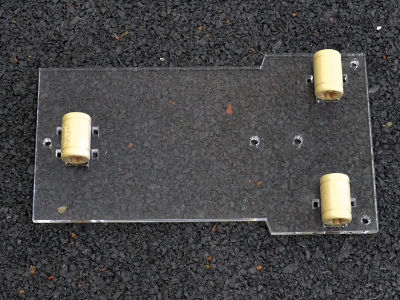

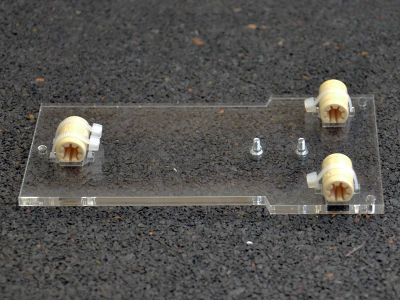

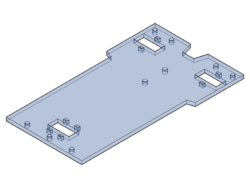

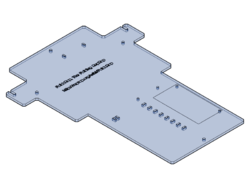

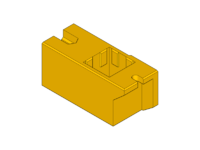

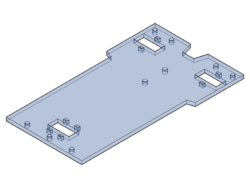

x1 underplate

x1 underplate

x1 power supply

x1 power supply

x2 M3x8

x2 M3x8

x2 M3 nut

x2 M3 nut

place the readable side of the underplate on the table

the terminal of the power supply is oriented downward

fix the power supply on the underplate with the screws and nuts

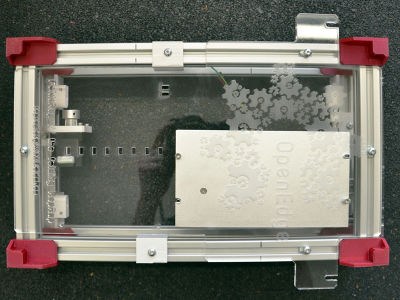

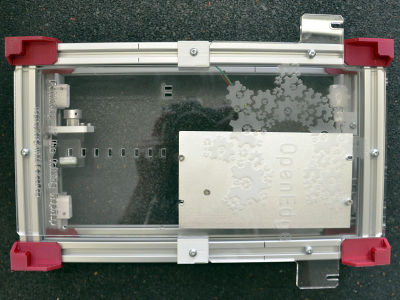

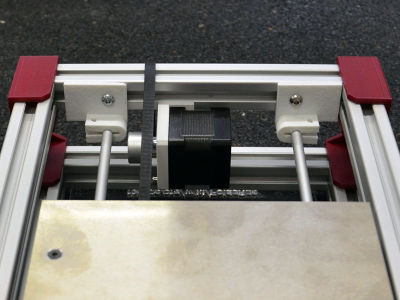

Underplate fixing

x4 M4x8

x4 M4x8

x4 T-nut

x4 T-nut

push them against the underplate and lock them again

Power supply wiring

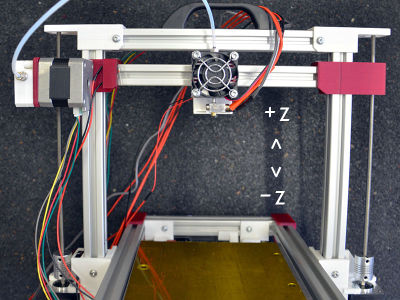

Step 5/20 - Z-axis (1 hour)

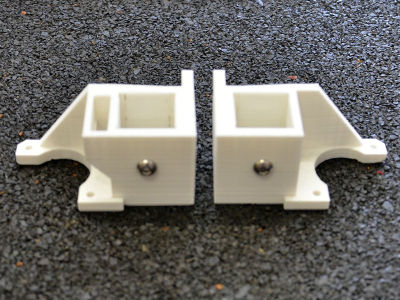

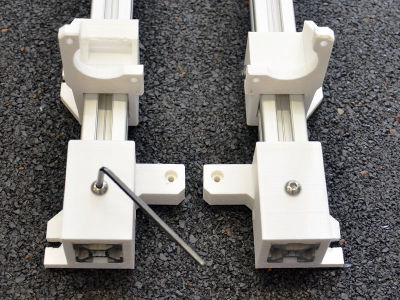

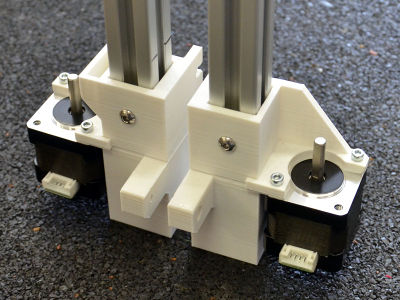

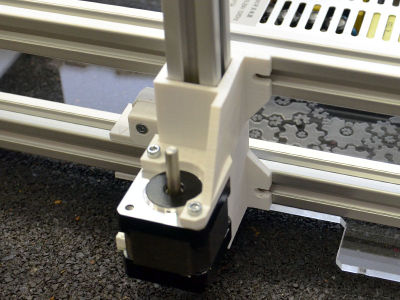

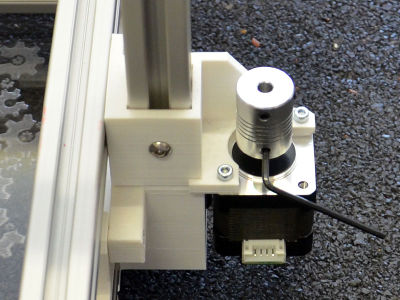

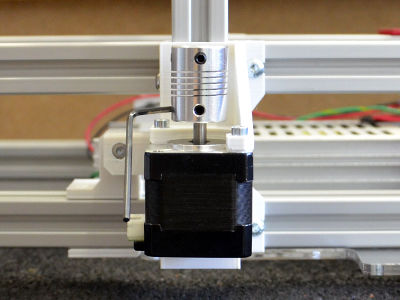

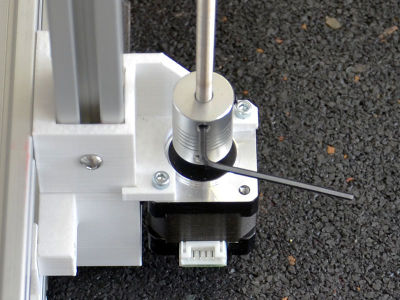

Z-motors (1/2)

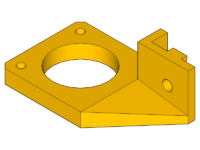

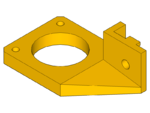

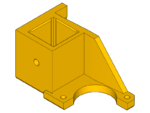

x1 z-motor left

x1 z-motor left

x1 z-motor right

x1 z-motor right

x2 300mm profile

x2 300mm profile

x2 M4x8

x2 M4x8

x2 T-nut

x2 T-nut

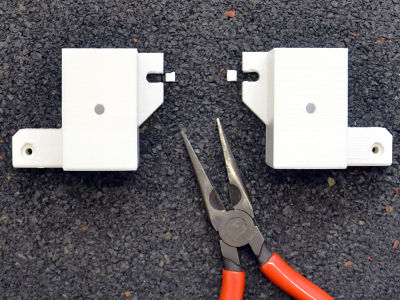

remove the support part of the z-motor parts with flat-nose pliers

screw T-nuts and M4x8 in the printed parts (without tightening)

place the z-motor parts on the aluminium profiles (without locking them)

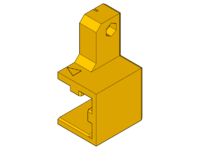

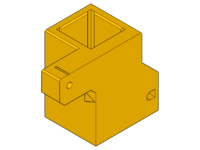

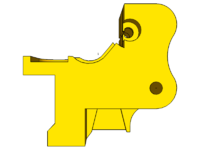

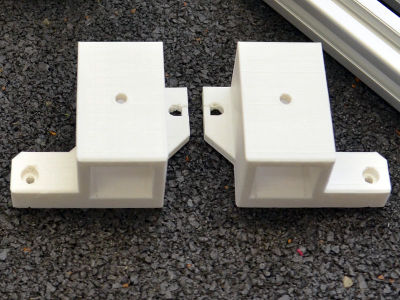

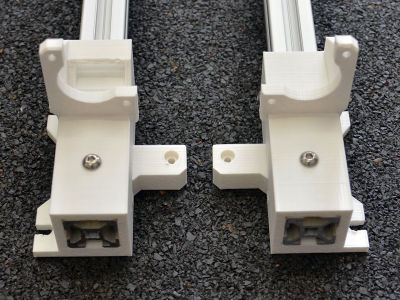

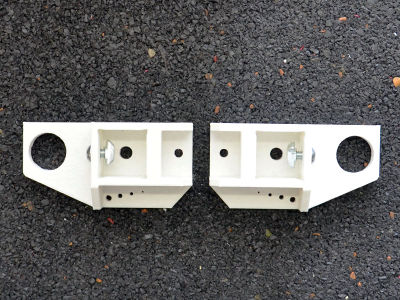

Outer hinges

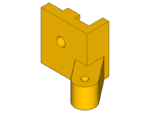

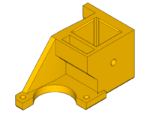

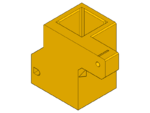

x1 hinge outer left

x1 hinge outer left

x1 hinge outer right

x1 hinge outer right

x2 M4x8

x2 M4x8

x2 T-nut

x2 T-nut

remove the support part of the z-motor parts with flat-nose pliers

screw T-nuts and M4x8 in the printed parts (without tightening)

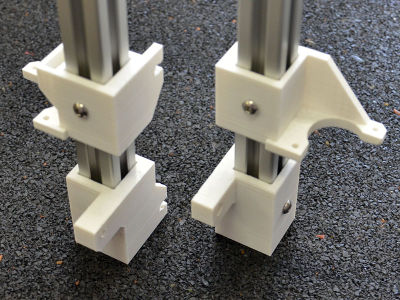

position the outer hinges under the z-motor parts (be careful with the orientation)

lock the outer hinges on the profiles: the bottom part of the aluminium profile and the bottom part of the outer hinge must be aligned

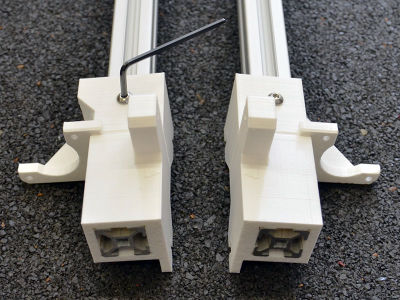

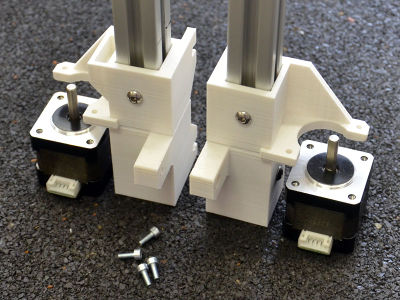

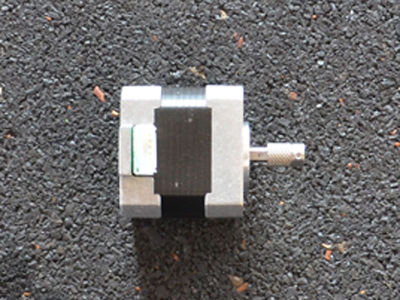

Z-motors (2/2)

x2 nema 14

x2 nema 14

x4 M3x8

x4 M3x8

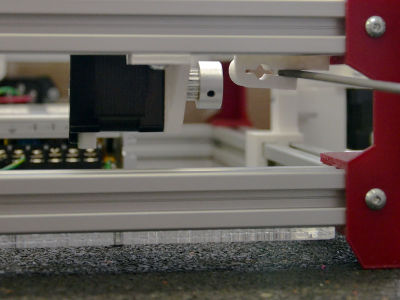

push the z-motor parts against the outer hinges...

position the motors (be careful with the connector orientation)...

... and fix them with M3x8

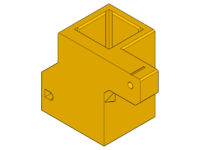

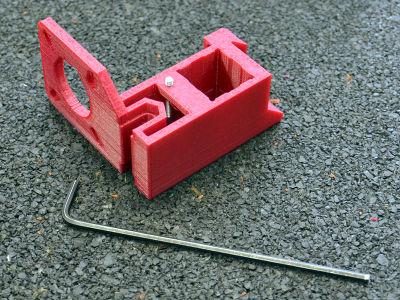

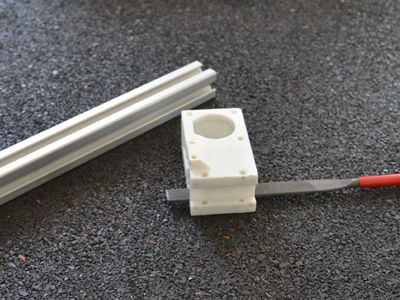

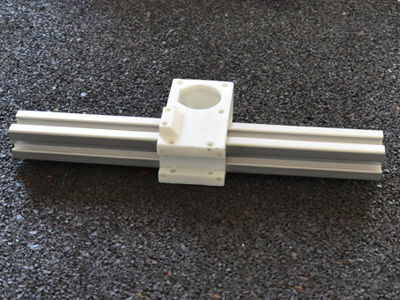

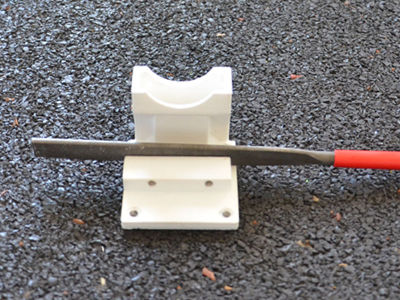

Z-sliders

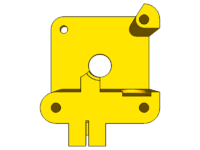

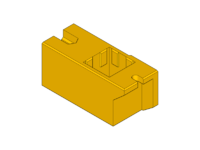

x1 Z-slider left

x1 Z-slider left

x1 Z-slider right

x1 Z-slider right

x1 M3x30 countersunk

x1 M3x30 countersunk

file the inside part of the z-sliders so that they slide easily (without play) on their profile

Z-axis

x2 M3 nut

x2 M3 nut

x2 M3x20

x2 M3x20

place the M3 nuts on the inner hinges...

... and screw the outer hinges on the inner hinges with the M3x20

the shape of the outer hinges fits with the shape of the inner hinges

x4 M4x8

x4 M4x8

x4 T-nut

x4 T-nut

lock them on the base frame with M4x8 and T-nuts

check the angle and adjust if necessary

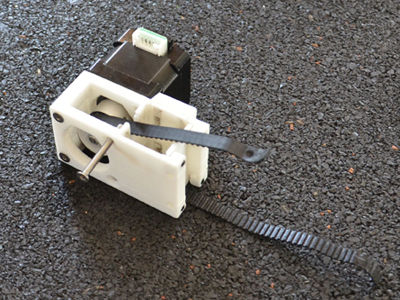

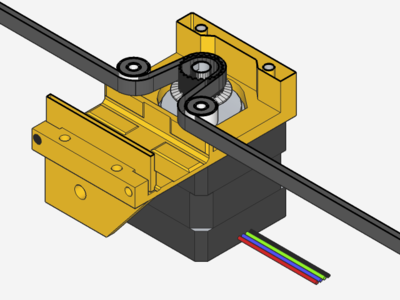

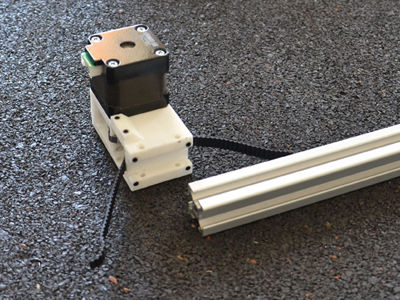

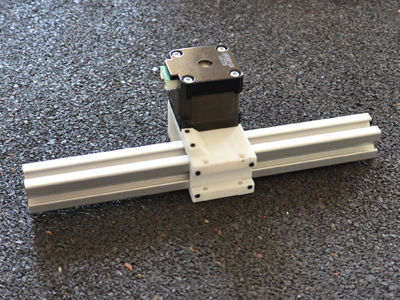

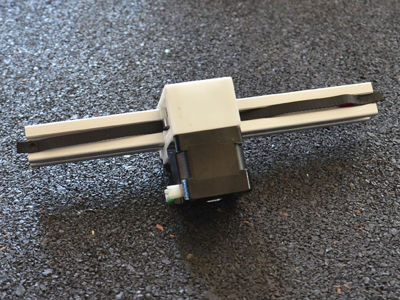

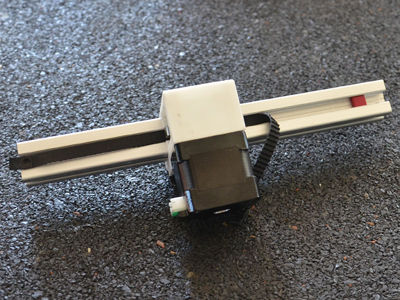

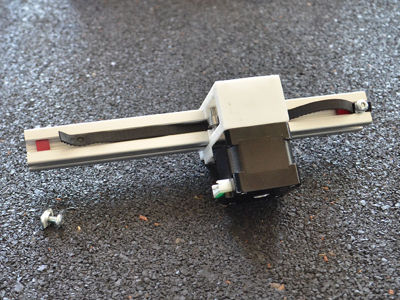

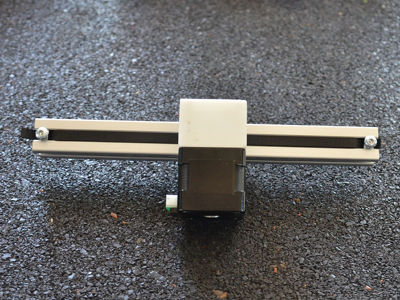

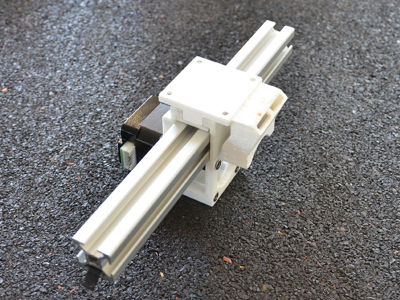

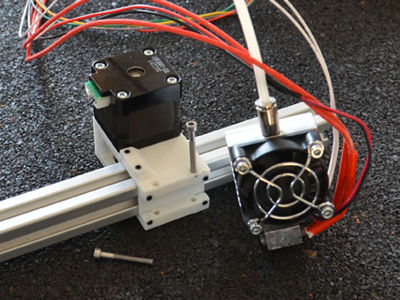

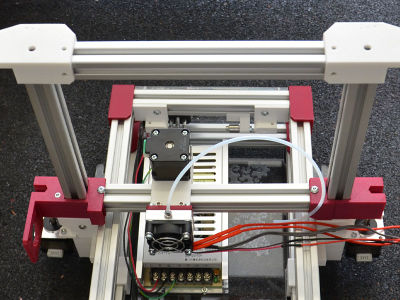

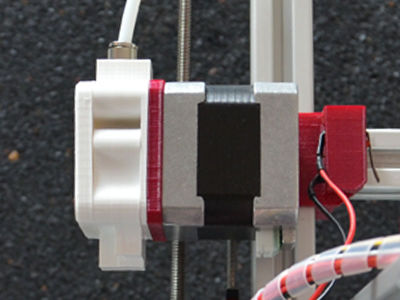

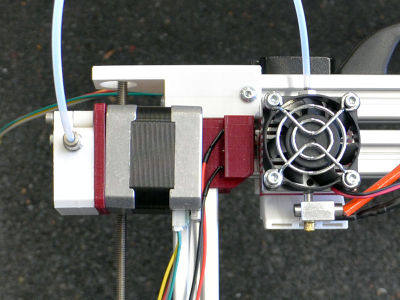

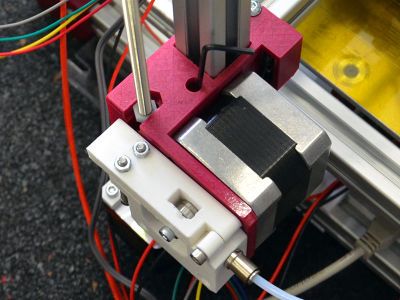

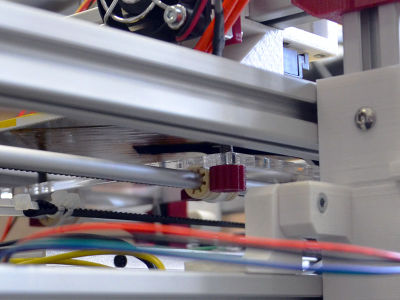

Step 6/20 - X-axis (1 hour)

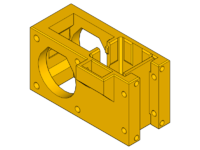

x1 x-carriage

x1 x-carriage

x1 200mm profile

x1 200mm profile

x6 grub screw

x6 grub screw

x1 nema 14

x1 nema 14

x1 pulley

x1 pulley

x2 grub screw

x2 grub screw

x4 M3x30 (countersunk)

x4 M3x30 (countersunk)

x2 603zz bearing

x2 603zz bearing

x1 250mm belt

x1 250mm belt

x2 x-belt end

x2 x-belt end

x2 M4x8

x2 M4x8

x2 T-nut

x2 T-nut

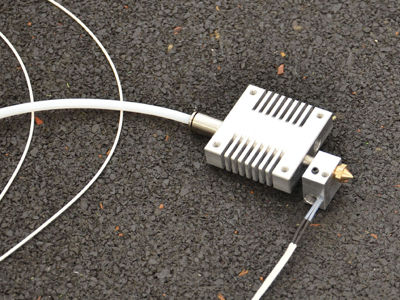

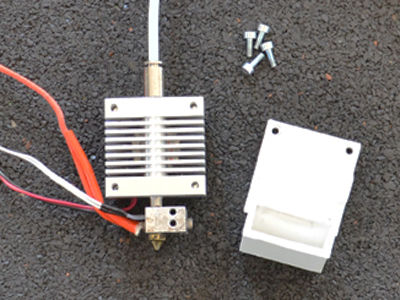

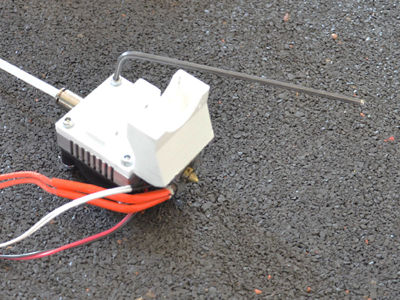

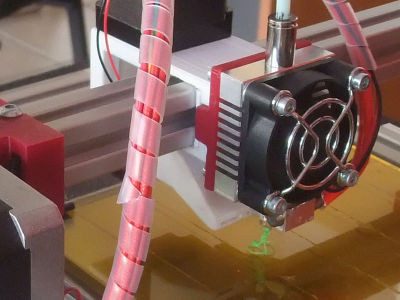

Step 7/20 - Hotend (1 hour)

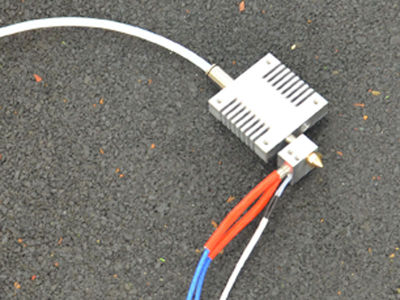

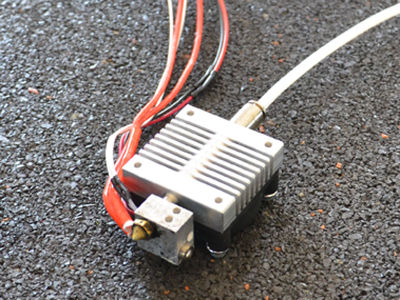

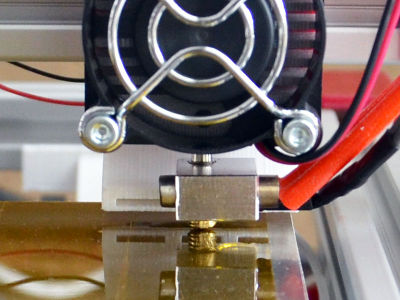

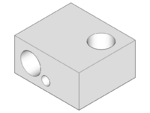

Heater block

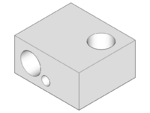

x1 heater block

x1 heater block

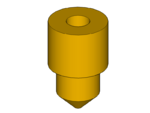

x1 nozzle

x1 nozzle

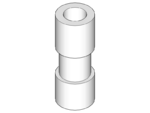

x1 barrel

x1 barrel

Heatsink

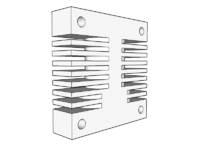

x1 heatsink

x1 heatsink

x1 pneumatic fitting

x1 pneumatic fitting

x1 PTFE tube (2-4 mm)

x1 PTFE tube (2-4 mm)

x1 grub screw

x1 grub screw

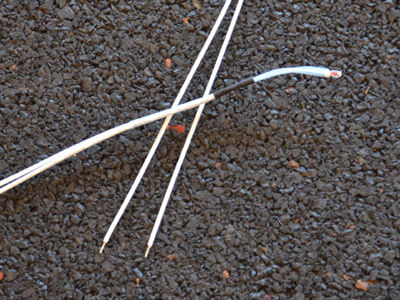

Thermistor

x1 thermistor

x1 thermistor

x2 female ferrule 2.54 mm

x2 female ferrule 2.54 mm

x1 2-pin casing

x1 2-pin casing

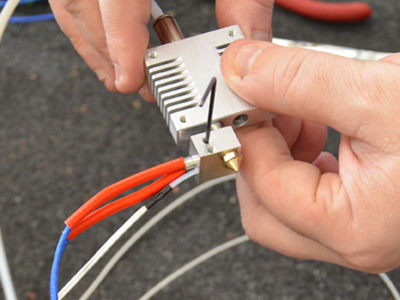

Cartridge heater

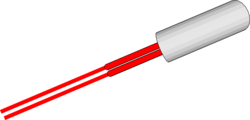

x1 cartridge heater

x1 cartridge heater

x1 grub screw

x1 grub screw

x2 cable terminal (1.5 mm)

x2 cable terminal (1.5 mm)

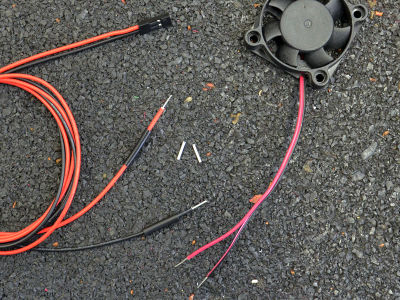

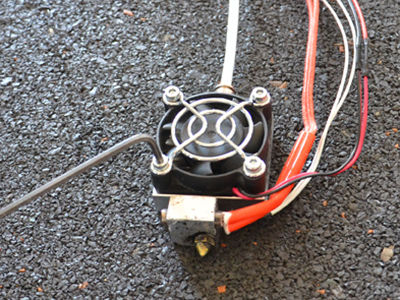

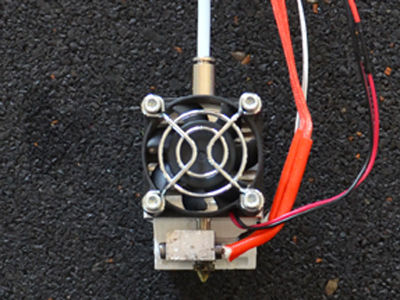

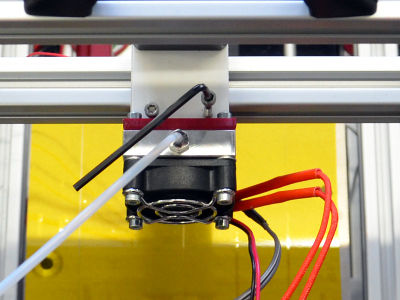

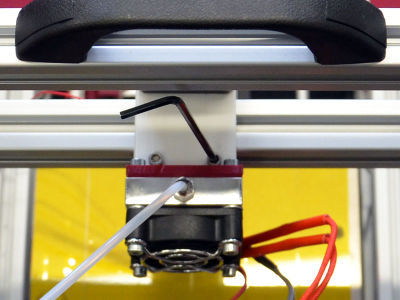

Fan

x1 fan

x1 fan

x2 ferrule (1mm)

x2 ferrule (1mm)

x2 heatshrink sleeve

x2 heatshrink sleeve

x1 fan-grill

x1 fan-grill

x4 M3x16

x4 M3x16

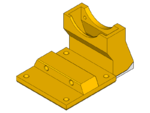

Hotend holder

x1 hotend holder

x1 hotend holder

x4 M3x8

x4 M3x8

x2 M3x25

x2 M3x25

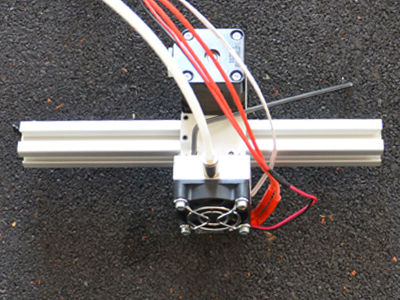

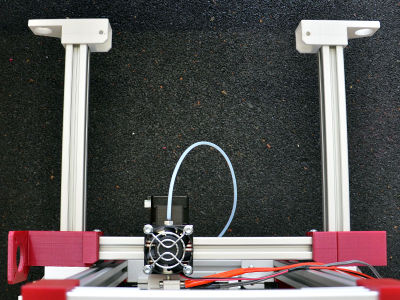

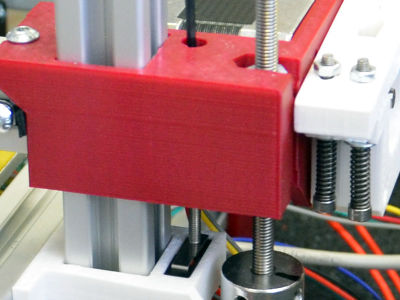

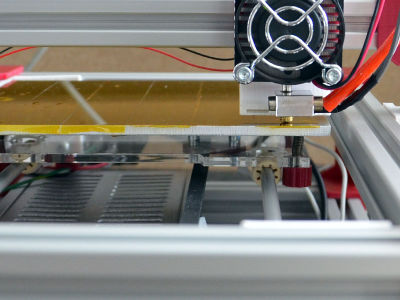

Step 8/20 - XZ-axis (1 hour)

x2 M4x8

x2 M4x8

x2 T-nut

x2 T-nut

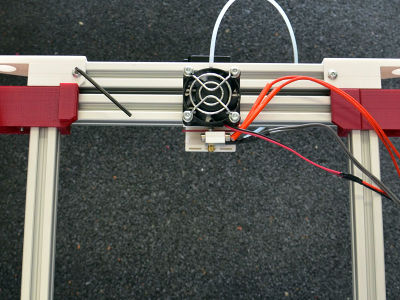

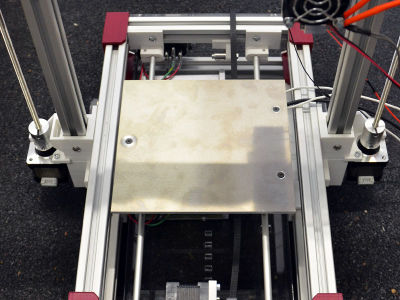

place the x-axis between the z-sliders...

... and fix them together with M4x8 and T-nuts

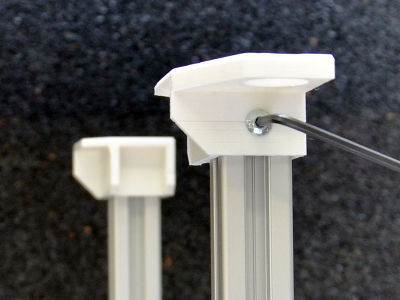

x1 z-top left

x1 z-top left

x1 z-top right

x1 z-top right

x1 200mm profile

x1 200mm profile

x2 M4x8

x2 M4x8

x2 T-nut

x2 T-nut

add M4x8 and T-nuts on the z-tops

position the z-tops over the z-axis profiles (be careful with the orientation)

check through the hole of the printed parts if the profiles touch the bottom part of the z-tops

position a 200m profile between the z-tops

move the x-axis up against the z-tops...

x4 M4x8

x4 M4x8

x4 T-nut

x4 T-nut

... and lock the 200mm aluminium profile

make sure that the z-axis profiles are parallel amongst themselves by sliding the x-axis up and down (adjust the z-profiles if necessary by unlocking / relocking the 200mm profile between the z-tops)

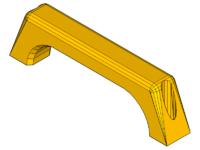

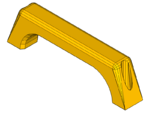

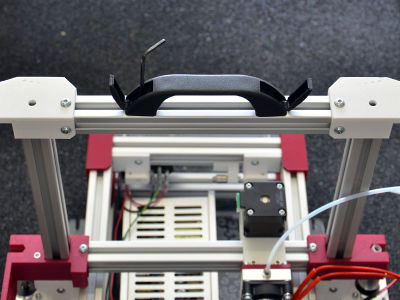

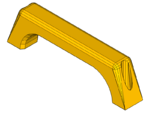

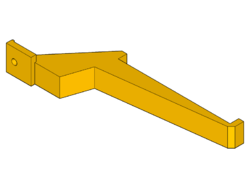

x1 handle

x1 handle

x2 M4x8

x2 M4x8

x2 T-nut

x2 T-nut

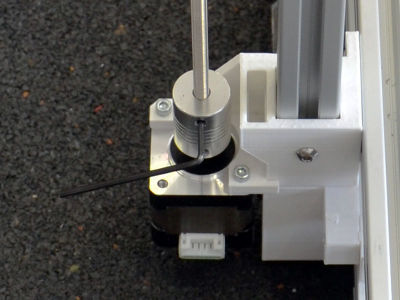

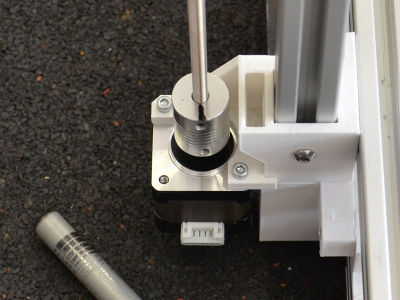

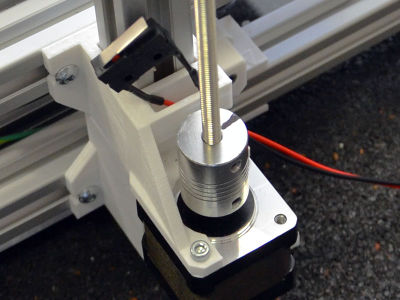

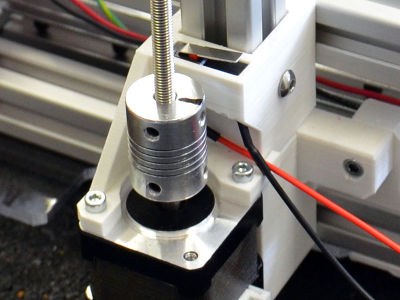

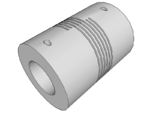

x1 flexible coupling

x1 flexible coupling

position the flexible coupling over the motor shaft and lock it on the flat part of the shaft with grub screws...

... so that the upper part of the flexible coupling is aligned with the upper part of the z-motor printed part

x2 nylon nut

x2 nylon nut

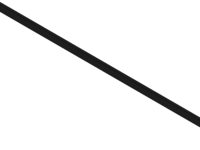

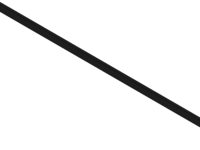

x1 threaded rod

x1 threaded rod

insert 2 nylon nuts in the z-sliders...

... and screw the threaded rod through them

make sure that there is NO PLAY between the nylon nuts and the z-sliders once the threaded rod are screwed (otherwise adjust the position of the nylon nuts in the printed part)

screw until it touches the motor shaft in the flexible coupling

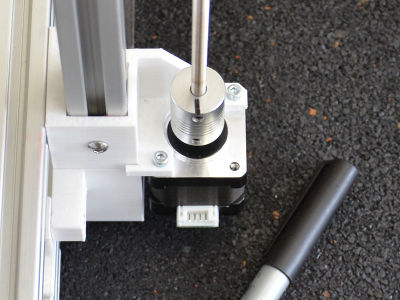

x1 flexible coupling

x1 flexible coupling

x2 nylon nut

x2 nylon nut

x1 threaded rod

x1 threaded rod

repeat the operations on the other side and turn the threaded rods until the z-sliders touch the z-tops

lock the threaded rods in the flexible couplings thanks to the grubscrew to keep the z-sliders in the correct position (parallel)

draw a parallel mark on both flexible couplings...

... to keep a visual point of reference of the parellelism of the x-axis with the rest of the machine

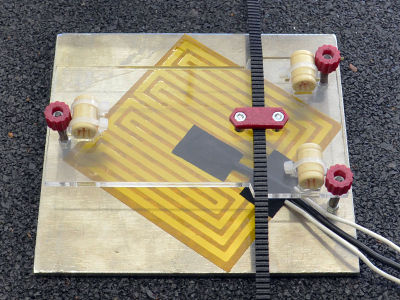

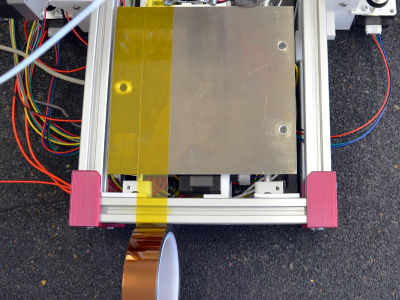

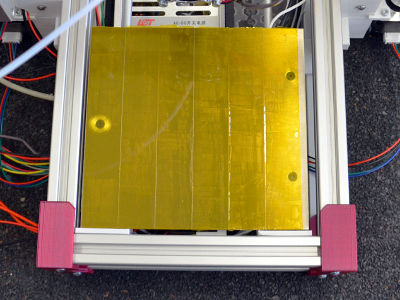

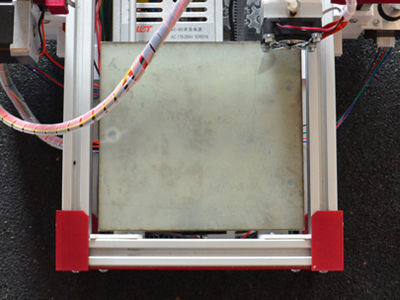

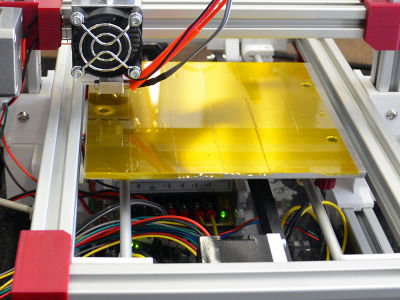

Step 9/20 - Bed (1 hour)

x3 M3x30 countersunk

x3 M3x30 countersunk

x3 M3 nut

x3 M3 nut

x3 spring

x3 spring

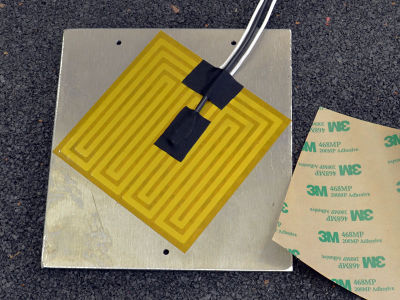

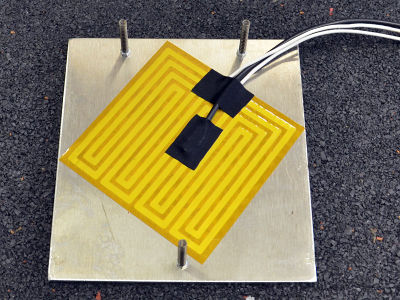

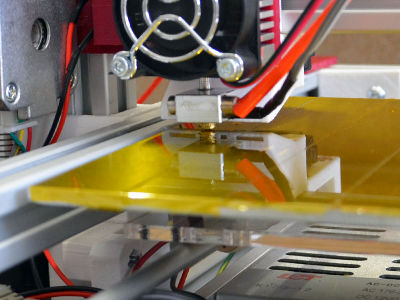

one side of the aluminium bed has countersunk holes...

... the other one not... position the bed so that the countersunk holes are against the table

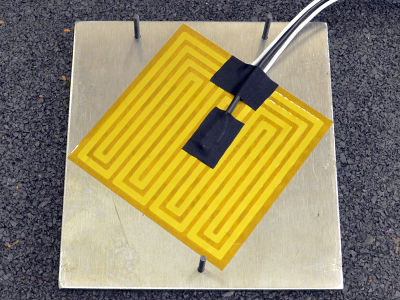

remove the plastic from the film heater and stick the film heater on the aluminium bed like shown on the picture (crooked to make the wires pass to the right of the right hole)

place the M3x30 countersunk in the holes

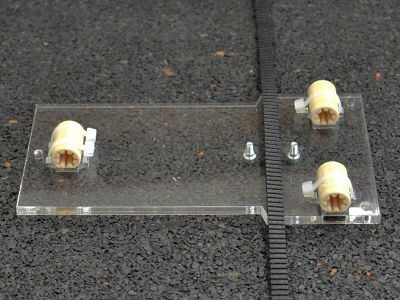

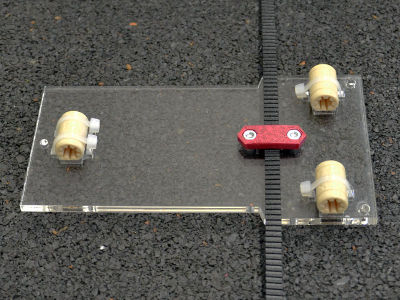

x1 y-carriage

x1 y-carriage

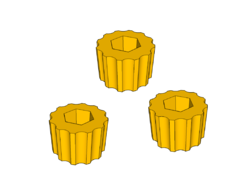

x3 linear bearing

x3 linear bearing

x4 zip-tie

x4 zip-tie

x2 M3x8

x2 M3x8

x1 600mm belt

x1 600mm belt

the bottom part of the belt must be aligned with the y-carriage corners and the belt middle must be aligned with both M3x8

x1 belt clamp

x1 belt clamp

x2 M3 nut

x2 M3 nut

screw the M3x8 in the belt clamp until the belt can't move anymore (the printed belt clamp distorts a bit)

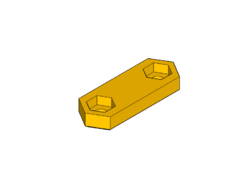

x3 bed adjuster

x3 bed adjuster

x3 M3 nut

x3 M3 nut

push the M3 nuts completely in the bed adjusters

if it's too tight you can help yourself with a M3x8 and a 2.5 hexagonal wrench

position the y-carriage over the aluinium bed and fix it with the bed adjusters: screw until the M3x30 countersunk extremities are aligned with the upper part of the bed adjusters (tighten completely the M3 nuts against the aluminium bed)

x2 smooth rod

x2 smooth rod

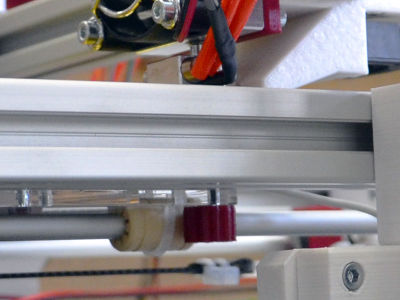

insert the smooth rods from the front side of the machine through the front rod-idler

pass the smooth rods through the linear bearings fixed on the bed (bed side with 2 linear bearings on the right smooth rod)

push the smooth rods through the rear rod-dlier

check if the bed slides well on the smooth rods

if the bed doesn't slide well you might adjust the space between the front rod-idlers to make the smooth rods parellel

place one extremity of the belt over the aluminium profile (make sure that the belt is parellel with the y-axis)

slide the y-motor part until the pulley teeth are aligned with the belt and lock it on the aluminium profile

place the other extremity of the belt over the aluminium profile (make sure that the belt is parellel with the y-axis)

slide the y-idler part until the bearings are aligned with the belt and lock it on the aluminium profile

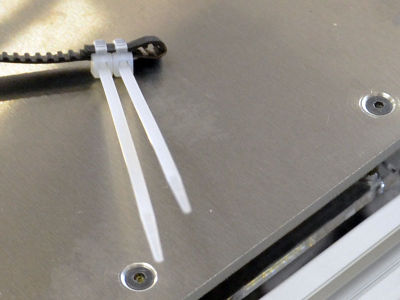

x5 zip-tie

x5 zip-tie

make a loop with one extremity of the belt and close it with 2 zip-ties

do it again with the other extremity

pass the belt over the pully...

pass a zip-tie through both loops... (be careful with not twisting the belt!)

... and tighten the zip-tie until the belt is taut

x2 cable terminal

x2 cable terminal

strip the extremities of the film heater wires

crimp firmly both cable terminals

x2 female ferrule (2.54mm)

x2 female ferrule (2.54mm)

x1 2-pin casing

x1 2-pin casing

shorten the sheath of the resistor

strip the extremity of both resistor wires

crimp firmly the ferrules on the wires

push the ferrules completely in the 2-pin casing

Step 10/20 - Endstops (30 min)

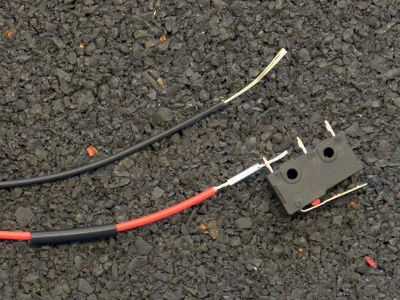

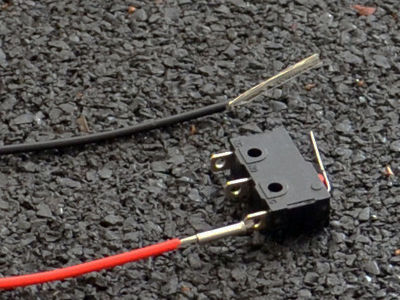

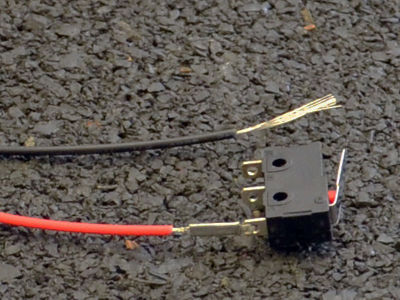

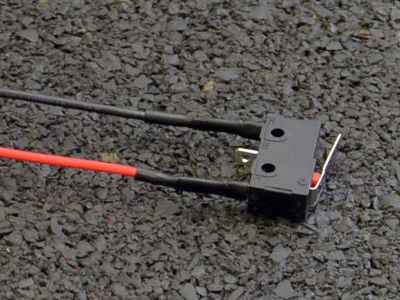

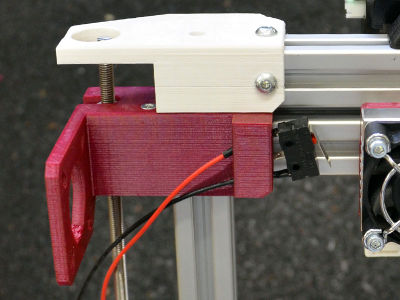

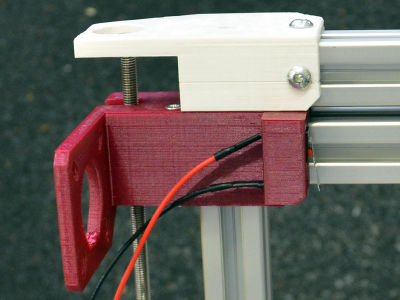

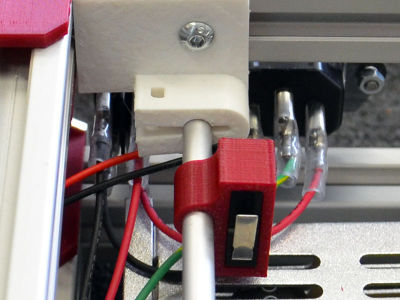

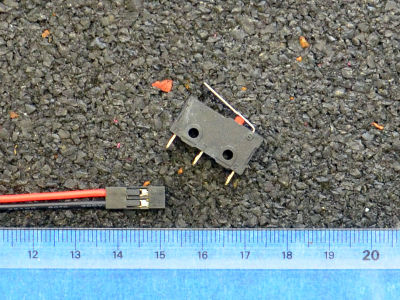

X-endstop

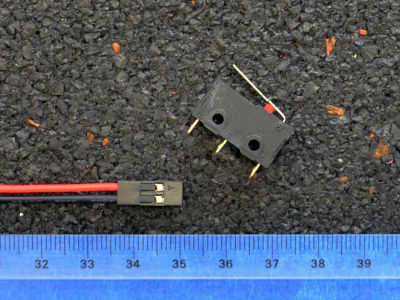

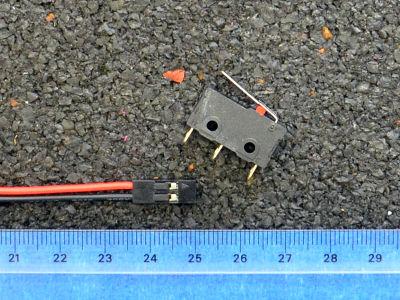

x1 endstop

x1 endstop

x2 heatshrink sleeve

x2 heatshrink sleeve

x2 ferrule

x2 ferrule

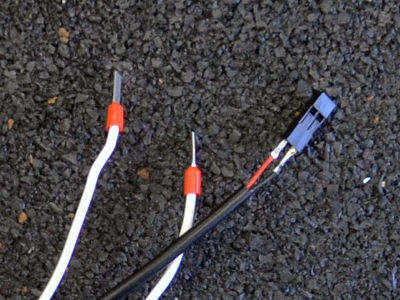

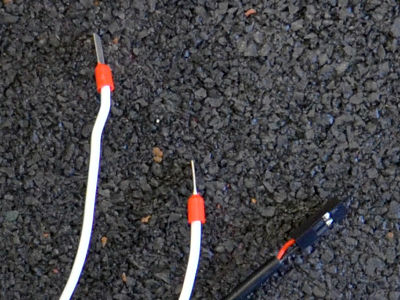

keep 35cm of a 2-pin wire with connector

strip 3cm at each extremity

add 2cm of heatshrink sleeve and a ferrule

pass the wire through one endstop extremity...

... and pass it back through the ferrule

position the heatshrink sleeve over the crimped ferrule...

... and heat it with a lighter

do it again with the other wire

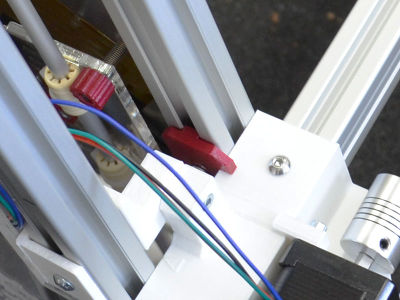

position the endstop in the z-slider... (strip oriented downward)

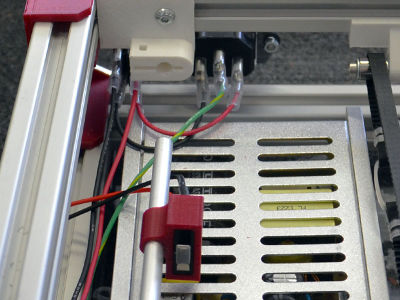

Y-endstop

x1 endstop

x1 endstop

x2 heatshrink sleeve

x2 heatshrink sleeve

x2 ferrule

x2 ferrule

x1 y-endstop holder

x1 y-endstop holder

keep 25cm of a 2-pin wire with connector

extend the endstop like previously

pass the endstop through the endstop holder (strip opposed to the endstop holder hook)

remove the left smooth rod from the rear rod-idler to add the endstop holder

push back the smooth rod through the rear rod-idler

Z-endstop

x1 endstop

x1 endstop

x2 heatshrink sleeve

x2 heatshrink sleeve

x2 ferrule

x2 ferrule

keep 15cm of a 2-pin wire with connector

(save the other part of the wires to extend the blower in the next step)

extend the enstop like previously

position the endstop in the z-motor...

Step 11/20 - Blower (15 min)

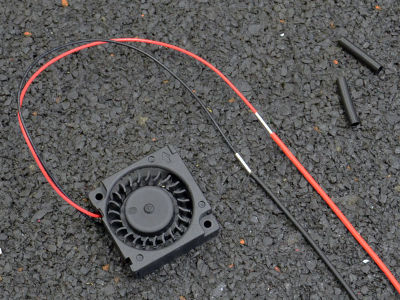

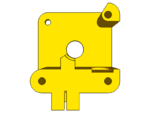

x1 blower

x1 blower

x2 ferrule

x2 ferrule

x2 heatshrink sleeve

x2 heatshrink sleeve

x2 cable terminal (1mm)

x2 cable terminal (1mm)

cut the connector of the blower...

... and strip the extremities

take wires you've saved from the z-endstop...

... and strip the extremities

extend the blower wires with 2 ferrules

cover with heatshrink sleeve...

... and heat them with a lighter

crimp firmly both cable terminals on the extremities

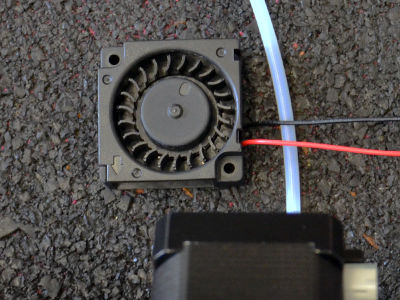

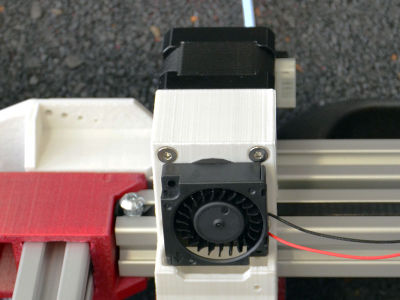

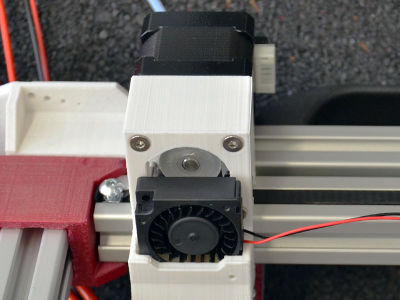

notice the arrow on the blower

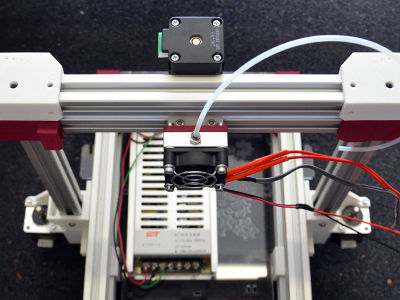

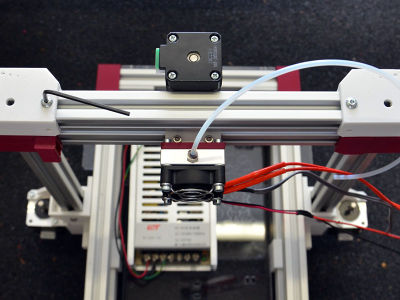

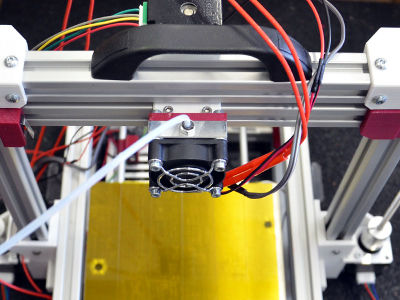

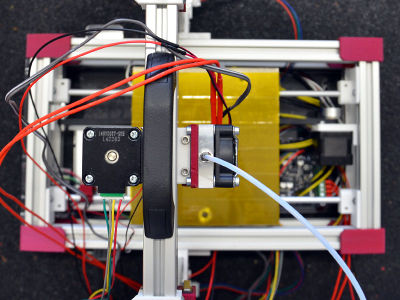

orient the blower over the x-slider: blades oriented downward and the arrow toward the inside of the x-slider

push completely the blower in the x-slider

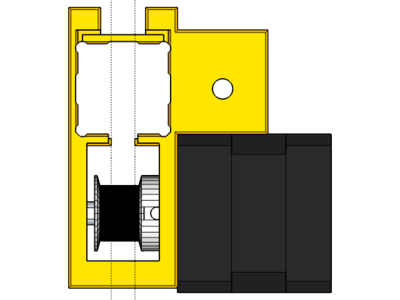

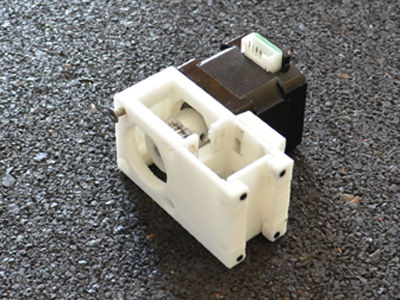

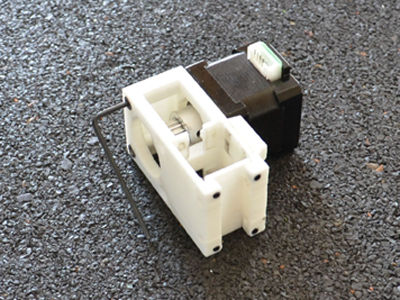

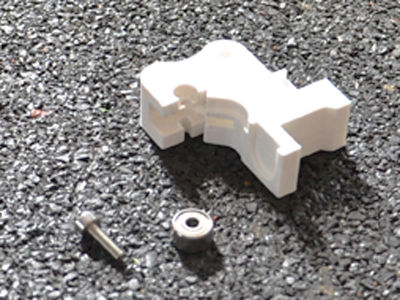

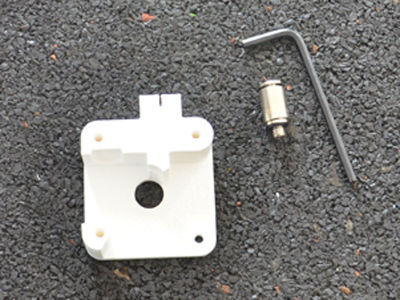

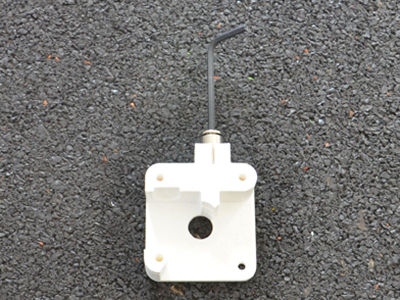

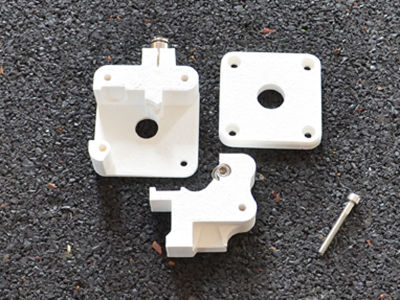

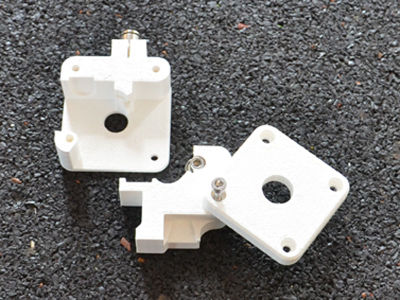

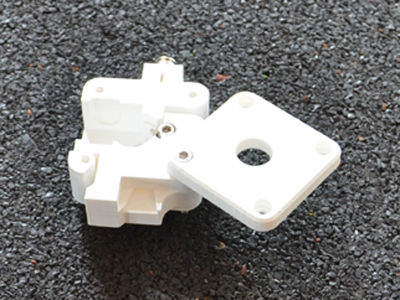

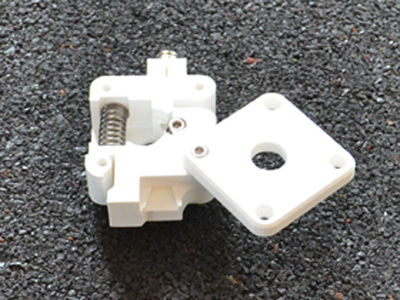

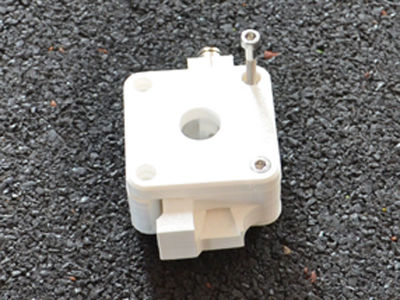

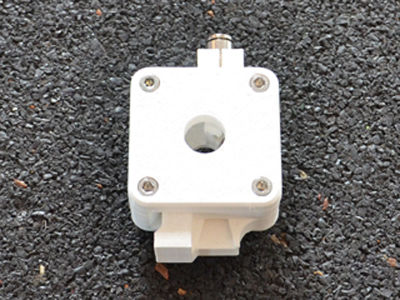

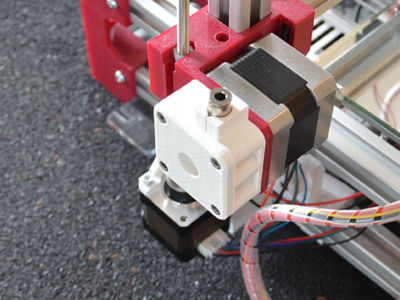

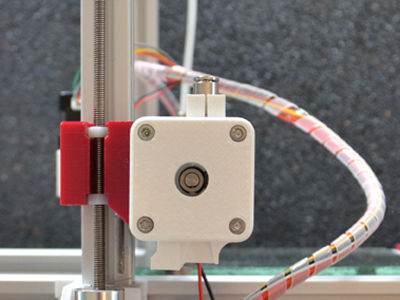

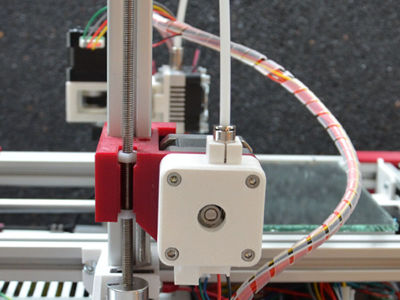

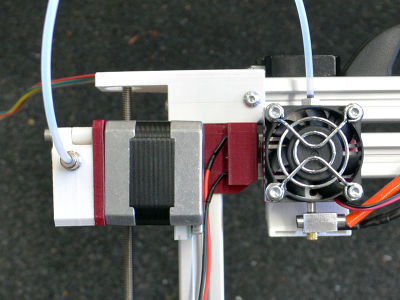

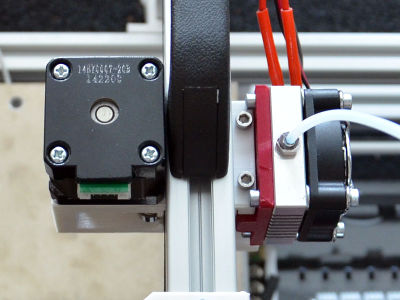

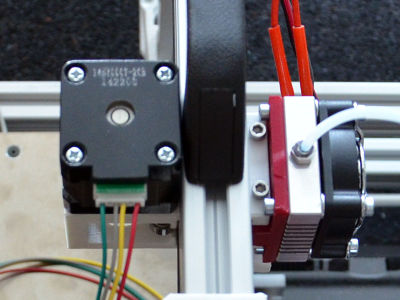

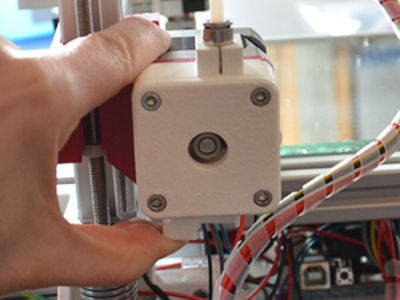

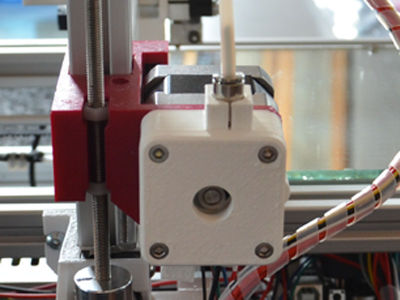

Step 12/20 - Extruder (45 min)

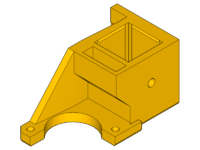

x1 extruder 1

x1 extruder 1

x1 extrudeur 2

x1 extrudeur 2

x1 extrudeur 3

x1 extrudeur 3

x1 M3x10

x1 M3x10

x1 603zz bearing

x1 603zz bearing

x1 pneumatic fitting

x1 pneumatic fitting

x1 M3x25

x1 M3x25

x1 spring

x1 spring

x3 M3x25

x3 M3x25

x1 nema 17

x1 nema 17

x1 insert (+ grub screw)

x1 insert (+ grub screw)

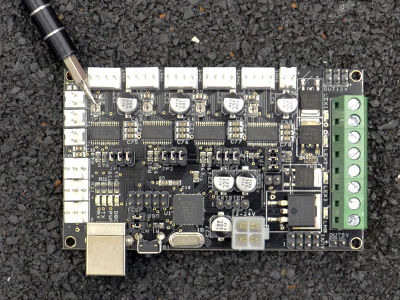

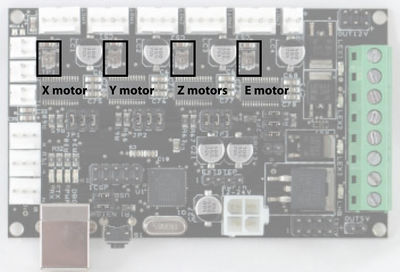

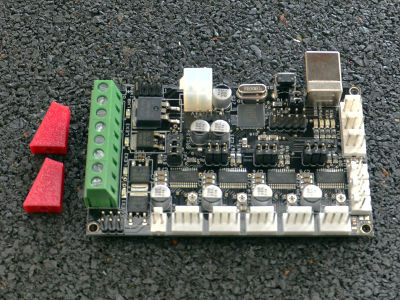

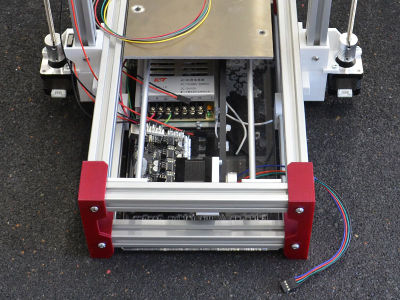

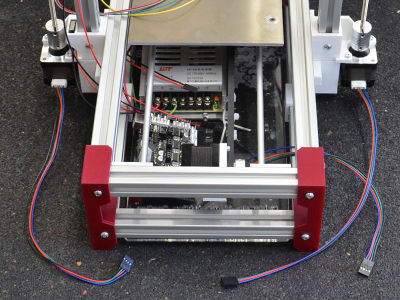

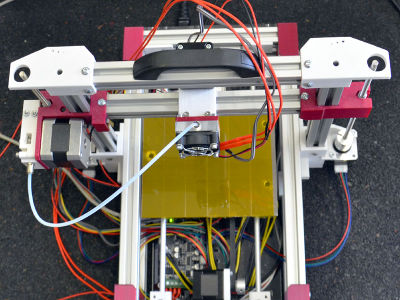

Step 13/20 - Electronic board (15 min)

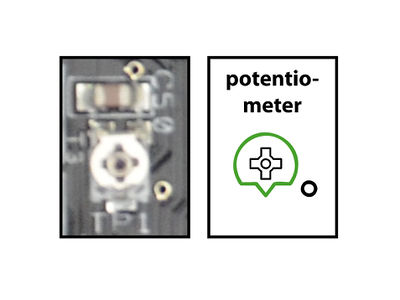

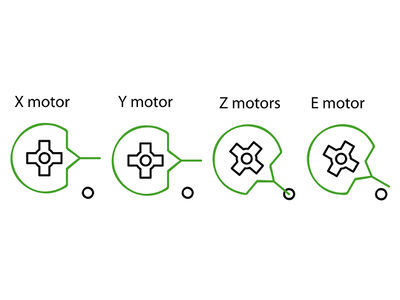

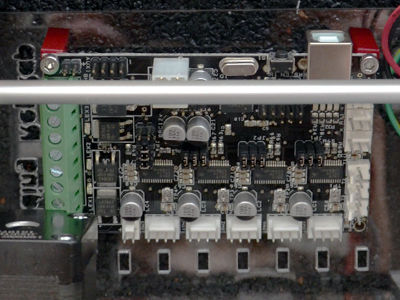

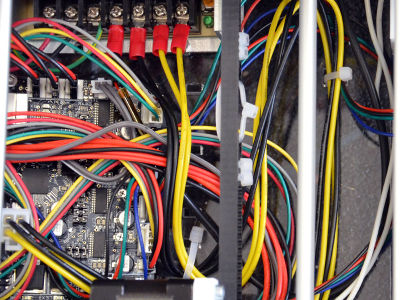

Potentiometers adjustment

turn the potentiometers COUNTERCLOCKWISE and SLOWLY to position them like on the drawing

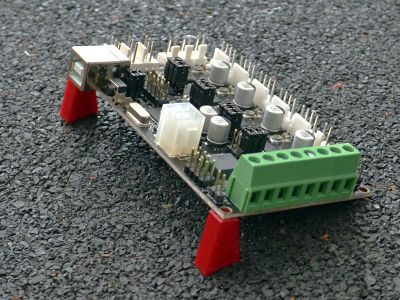

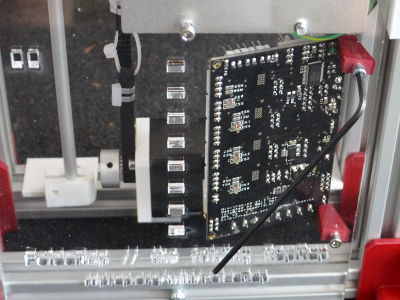

Electronic board fixing

x2 board mount

x2 board mount

x2 M3x8

x2 M3x8

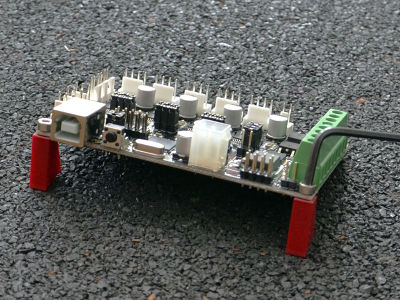

position the board mounts the same side as the USB port

fix the electronic board on the board mounts with M3x8

x2 M3x8

x2 M3x8

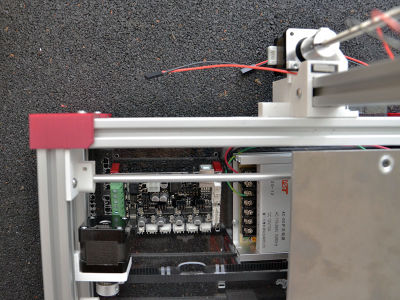

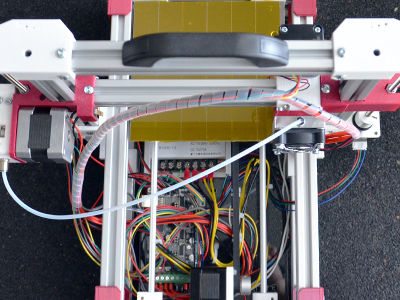

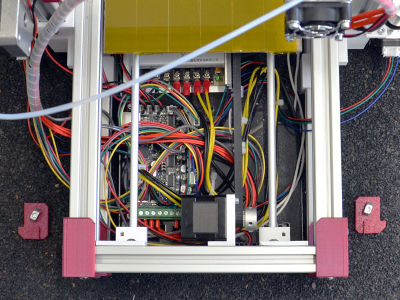

place the electronic board in the machine under the power supply

USB port oriented outward

screw the board mounts on the underplate (from underneath)

Step 14/20 - Wiring (45 min)

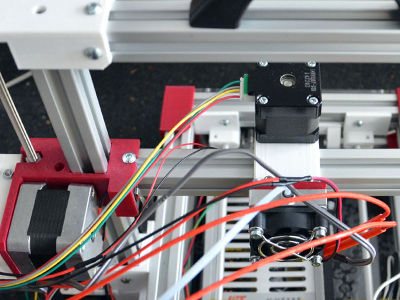

E-motor

plug long wires (70cm) + connector to the extruder motor

X-motor

plug long wires (70cm) + connector to the x-motor

Y-motor

plug short wires (30cm) + connector to the y-motor

Z-motors

plug short wires (30cm) + connector to the z-motors

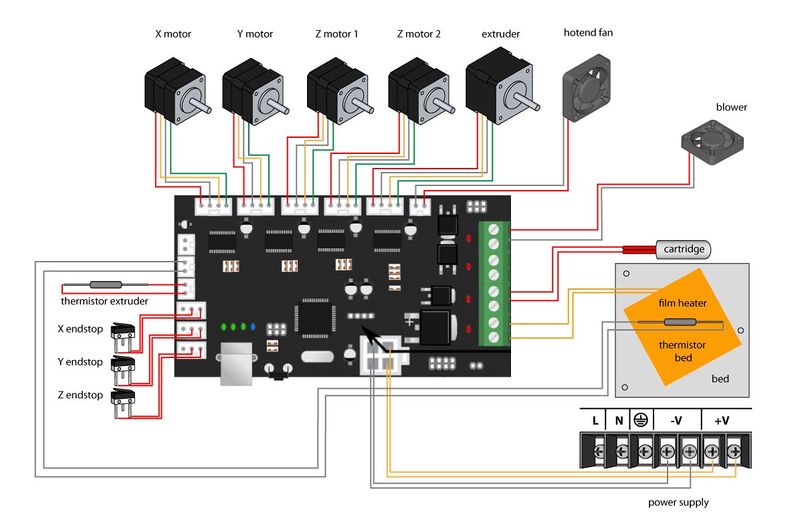

Electronic board

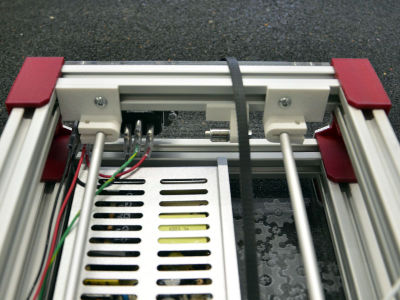

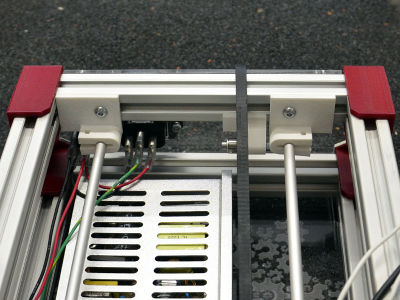

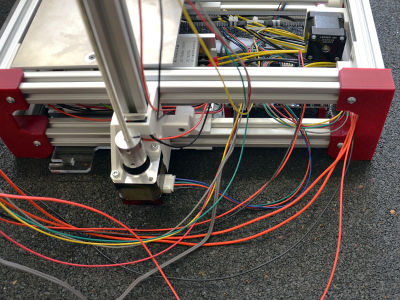

connect the wires according to the drawing (be careful with the wires colour) and pay attention to the following points:

... every hotend cable must pass OVER the x-axis aluminium profile and join themselves on the hotend left side

... every cable mus pass through the rectangle made up from: the upper and the bottom aluminium profiles AND the z-axis and the front feet

... the cables must be flat enough so that they don't disturb the bed movements

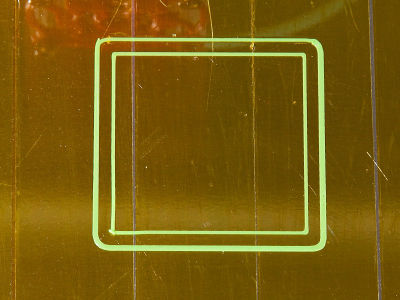

Step 15/20 - Printing surface (30 min)

Kapton (option 1)

the plastic doesn't stick on aluminium: cover the aluminium bed with Kapton

make sure that there is no air bubbles between the Kapton and the bed

bring the hotend in the middle of the x-axis

bring the bed in the middle of the y-axis

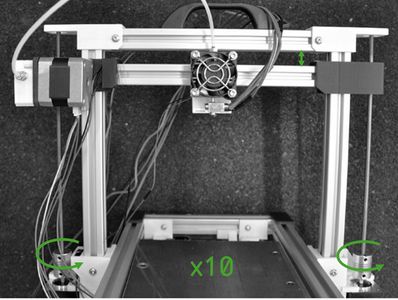

bring the x-axis down by turning manually counterclockwise the flexible couplings (around 10 times)

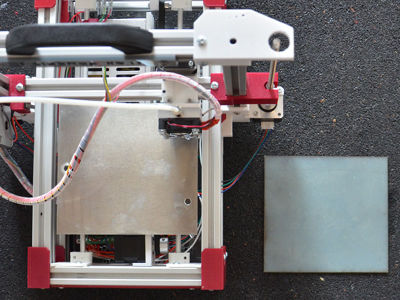

PrintBite (option 2)

remove the adhesive film from the PrintBite surface...

... and stick it on the aluminium bed

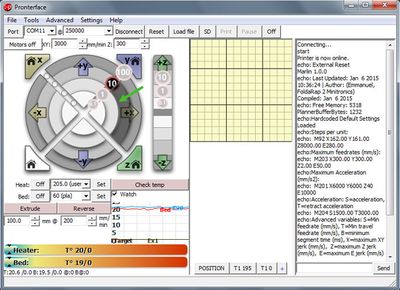

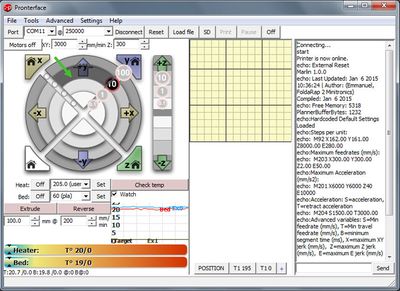

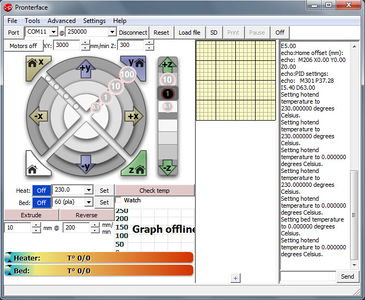

Step 16/20 - Driver (15 min)

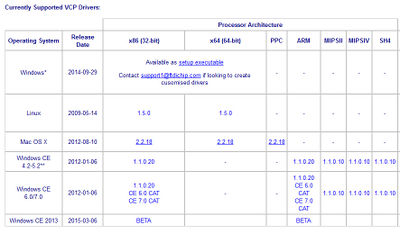

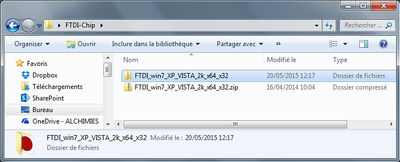

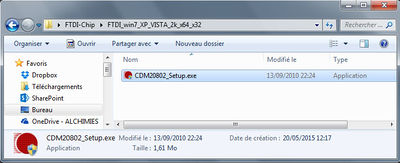

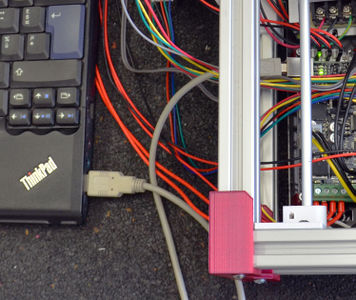

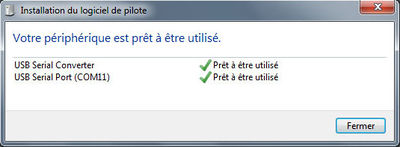

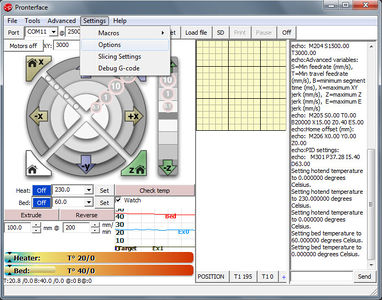

connect the 3D-printer to your computer

note the USB port COM number

Step 17/20 - Firmware (15 min)

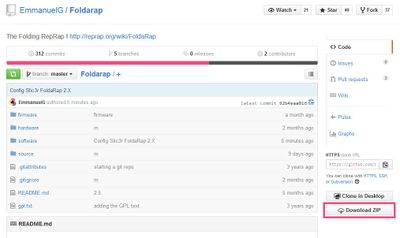

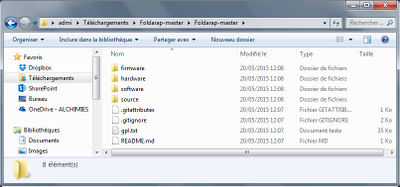

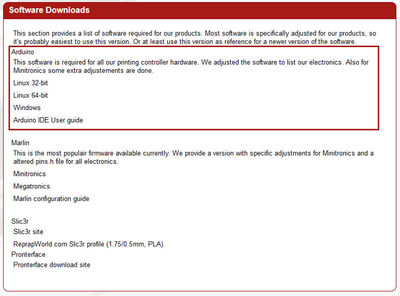

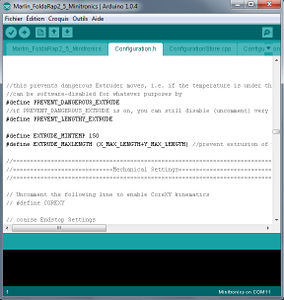

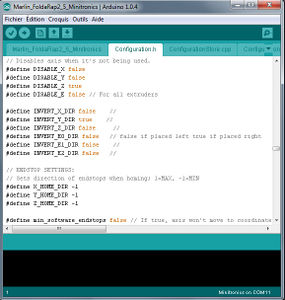

open the .ino file: FoldaRap > Firmware > Marlin_FoldaRap2_6_Minitronics > Marlin_FoldaRap2_6_Minitronics.ino

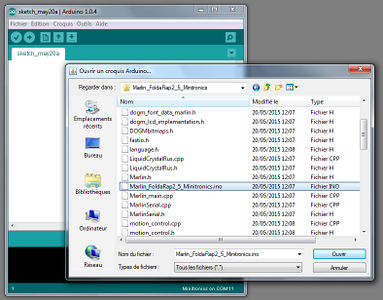

select the electronic board type > Ministronics

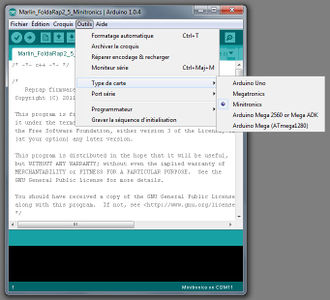

select the port COM number

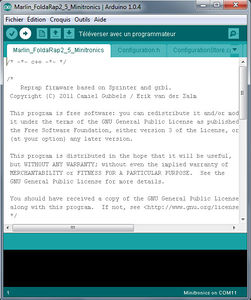

transfer the firmware on the electronic board

Step 18/20 - Software (35 min)

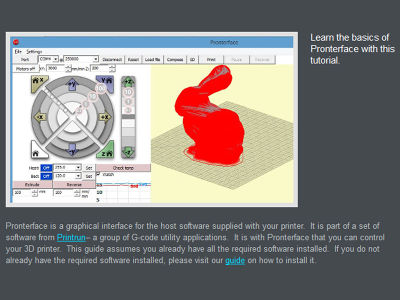

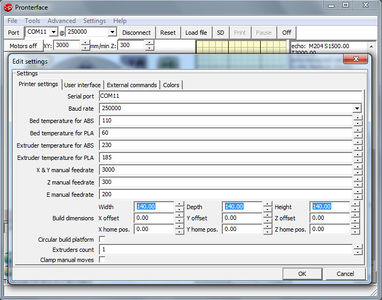

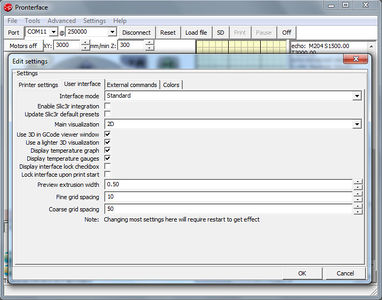

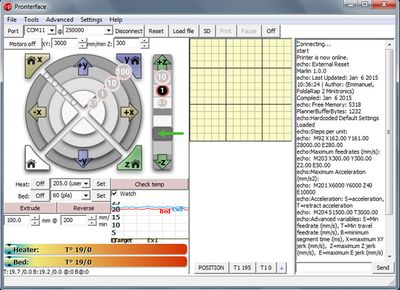

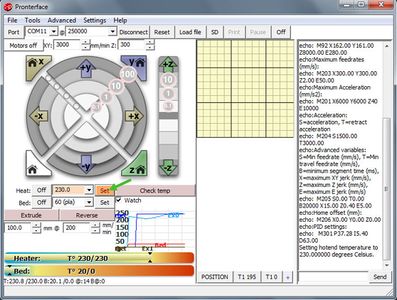

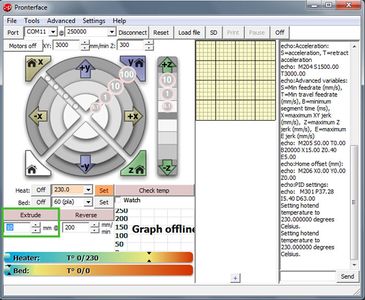

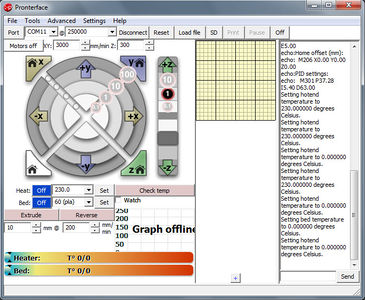

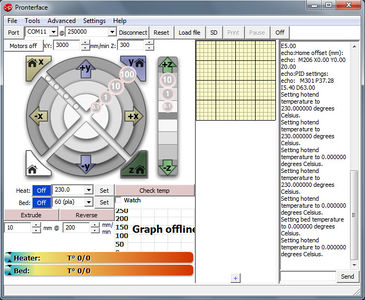

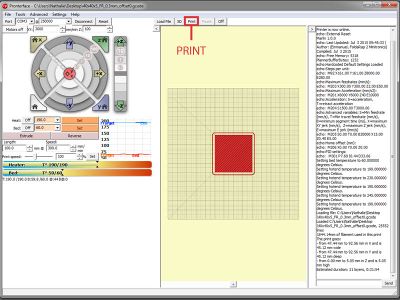

User interface

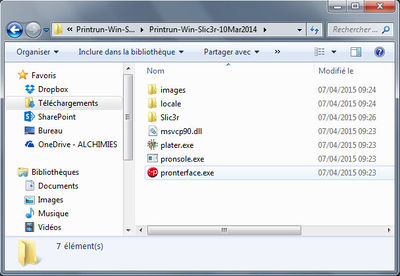

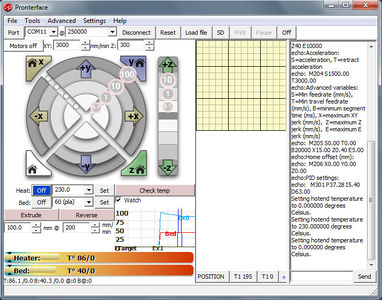

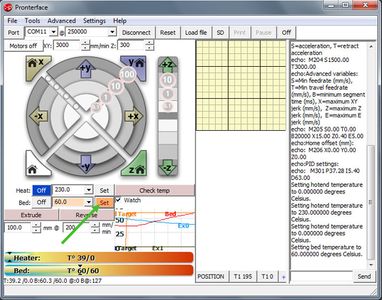

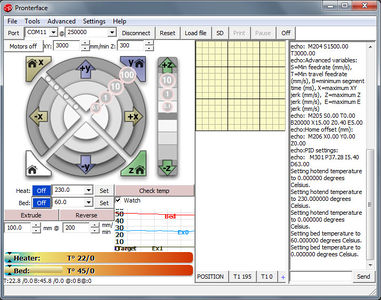

extract the files and open Pronterface

enter the bed size: 140x140x135

tick the box "display temperature gauges"

close the Pronterface window and restart the software; connect the 3D-printer to the correct port COM number (@115200 baudrate)

Testing

Preparation

bring the hotend in the middle of the x-axis

bring the bed in the middle of the y-axis

bring the x-axis down by turning manually counterclockwise the flexible couplings (around 10 times)

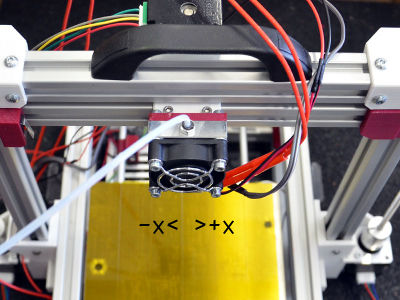

Switching on

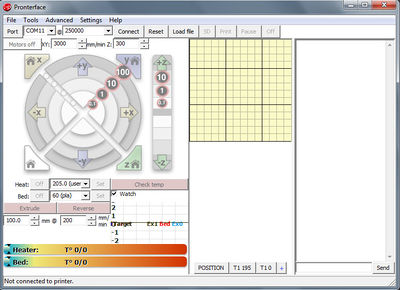

X testing

test the x-motor movement: (+)10X moves the hotend of 10mm to the right (the hotend moves away from the x-endstop)

(-)10X moves the hotend of 10mm to the left (the hotend moves closer to the x-endstop)

If the motor rotation is reversed go the the "readjustments" paragraph...

Y testing

test the y-motor movement: (+)10Y moves the bed of 10mm to the front (the bed moves away from the y-endstop)

(-)10Y moves the bed of 10mm to the back (the bed moves closer to the y-endstop)

If the motor rotation is reversed go the the "readjustments" paragraph...

Z testing

test the z-motor movement: (+)1Z moves the hotend of 1mm to the top (the hotend moves away from the z-endstop)

(-)1Z moves the hotend of 1mm to the bottom (the hotend moves closer to the z-endstop)

If the motor rotation is reversed go the the "readjustments" paragraph...

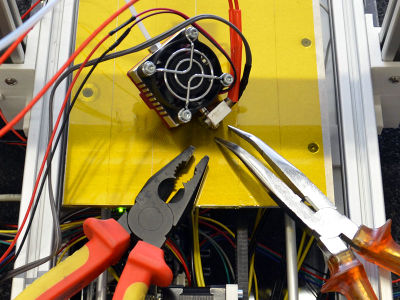

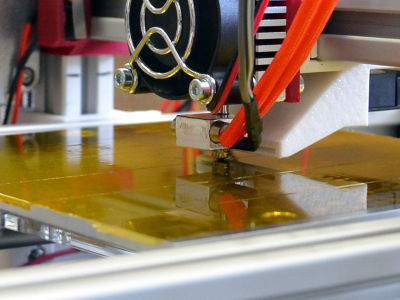

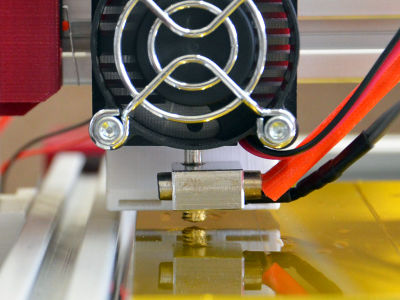

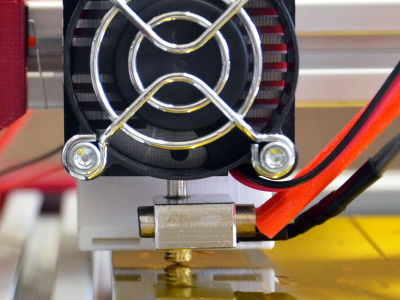

Hotend testing and adjustment

set the hotend temperature to 230°C

remove the hotend from the x-axis (be careful: it's hot! use gloves): as the metal parts distort because of the heat it's necessary to screw tighter the nozzle in the heater block to make the junction with the barrel airtight

use 2 pair pliers to do that: 1 pair to hold the heater block and 1 pair to screw the nozzle

replace the hotend on the x-axis

Extruder testing

while the hotend is hot push the extrude botton with 10mm (if the hotend temperature is < 150°C the printer will protect itself and won't extrude)

the e-motor turns COUNTER clockwise

stop heating up the hotend

If the motor rotation is reversed go the the "readjustments" paragraph...

Bed testing

set the bed temperature to 65°C

Readjustments

if the motors rotation is reversed then disconnect the 3D-printer from Pronterface and re-open the firmware in Arduino 1.6.3 >> Configuration.h >> "Mechanical Settings" paragraph

define INVERT_?_DIR false // write "true" instead of "false" (or the contrary) for the axis which need to be reversed and transfer the new version of the firmware on your electronic board

test again the motors rotation

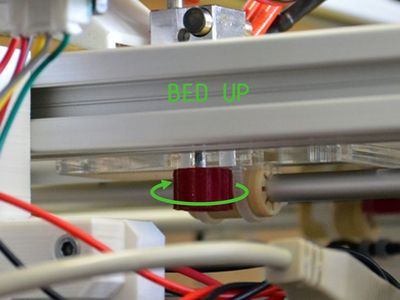

Step 19/20 - Bed calibration (20 min)

thanks to the Pronterface console move the nozzle over the middle of the bed...

... and move it down until the nozzle touches the bed without putting pressure on it

screw the M3x30 contersunk in the z-slider...

... until it touches the z-endstop

thanks to the Pronterface console move the nozzle up (+)3Z...

... and bring the nozzle over the first M3x30 countersunk

bring the nozzle to its Z origin (HOME Z)

IF the nozzle doesn't touch the bed...

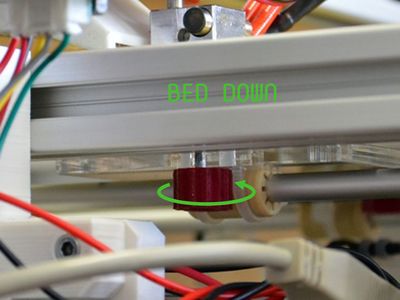

... turn the bed adjuster clockwise...

... until the nozzle touches the bed without putting pressure on it

IF the nozzle puts pressure on the bed...

... turn the bed adjuster counterclockwise...

... until the nozzle touches the bed without putting pressure on it

thanks to the Pronterface console move the nozzle up (+)3Z...

... and bring the nozzle over the second M3x30 countersunk

bring the nozzle to its Z origin (HOME Z)

adjust the space between the nozzle and the bed with the bed adjuster...

... until the nozzle touches the bed without putting pressure on it

thanks to the Pronterface console move the nozzle up (+)3Z...

... and bring the nozzle over the third M3x30 countersunk

bring the nozzle to its Z origin (HOME Z)

adjust the space between the nozzle and the bed with the bed adjuster...

... until the nozzle touches the bed without putting pressure on it

thanks to the Pronterface console move the nozzle up (+)3Z

Step 20/20 - Finishing touches (30 min)

Spiral sheath

Once your are sure that every part of the 3D-printer is adjusted you can bring the finishing touches:

bring order to the cables path...

... by organising them with the spiral sheath...

... and zip-ties fixed on the underplate

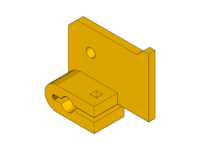

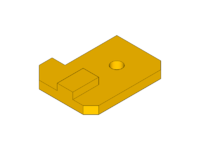

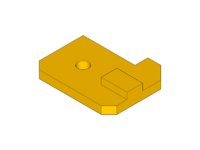

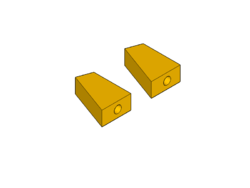

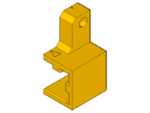

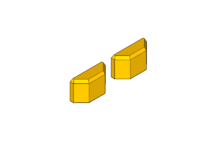

Hinges-blocks

x1 hinge block left

x1 hinge block left

x1 hinge block right

x1 hinge block right

x2 M4x8

x2 M4x8

x2 T-nut

x2 T-nut

screw the hinges-blocks on the aluminium profile...

... so that you can find back the correct position of the z-axis after folding / unforlding your FoldaRap

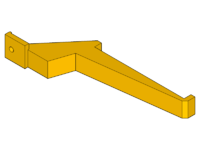

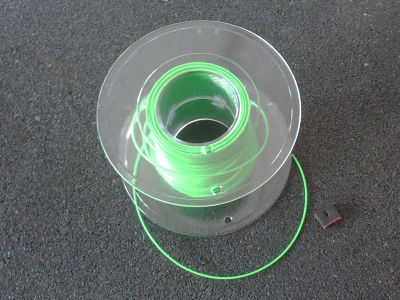

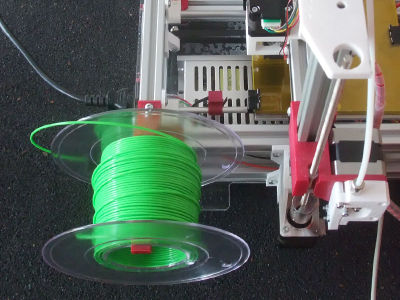

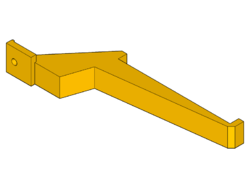

Spool holder

x1 spool-holder

x1 spool-holder

x1 M4x8

x1 M4x8

x1 T-nut

x1 T-nut

fix the spool holder over the left rear foot (the same side as the extruder)

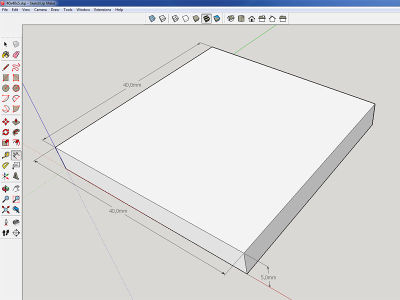

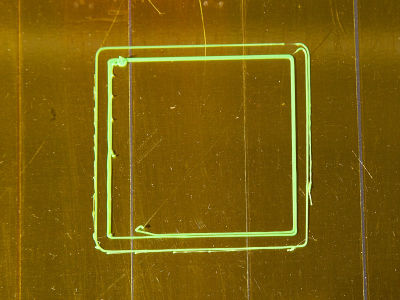

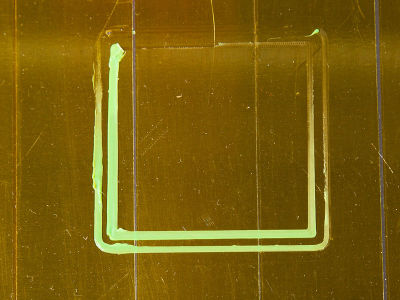

1st printing

Modelling

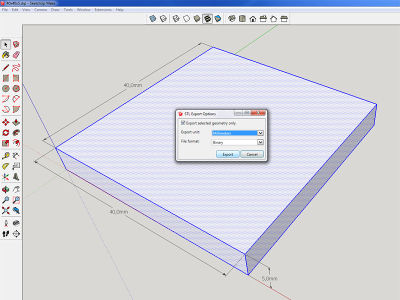

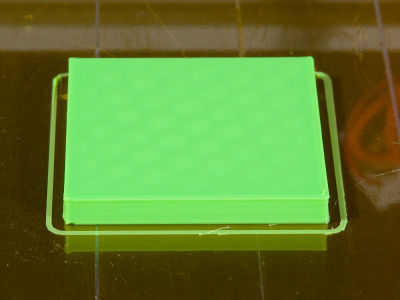

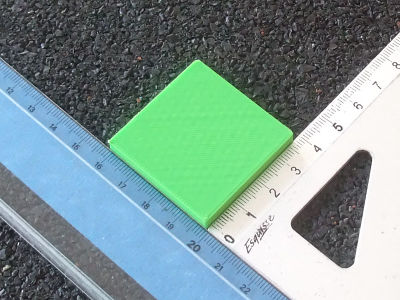

draw a 40x40x5mm parallelepipoid on any computer aided design (CAD) software: Blender, 3D Slash, SketchUp, etc.

export the parallelepipoid as an .stl file (and under the CAD software extension)

Netfabb Basic

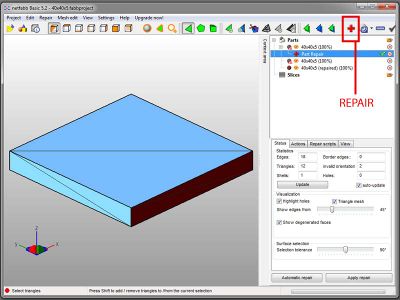

Check the quality of your .stl file on Netfabb Basic: you might "repair" or re-arrange your .stl file on Netfabb

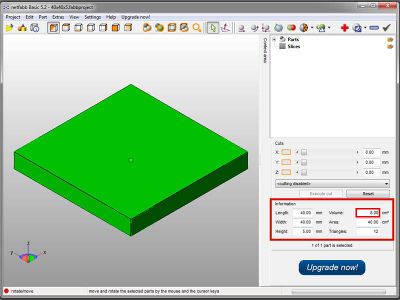

open your .stl file in Netfabb Basic: if the file is ok every face appears in green and the software gives you the volume value in the right panel (you can also check the dimensions of your model)

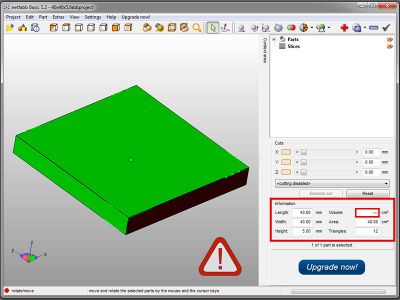

if the .stl file is wrong: a warning sign appears and the software doesn't give you the volume value

to repair the .stl file: click on the red cross button (REPAIR)

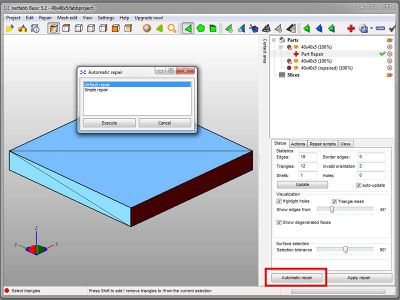

select the automatic repair

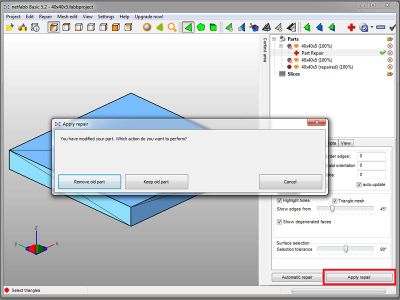

apply repair and remove old part

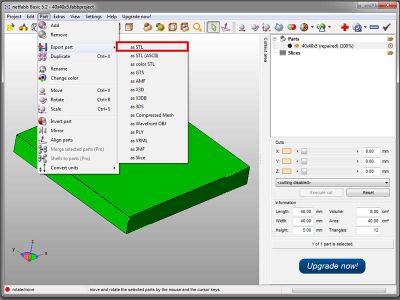

don't forget to save the new version of your file: Part > Export part > as STL

If the automatic repair doesn't wotk: use the red cross button to identify the origin of the problem and re-open your file under the CAD software extension to correct the problem manually (don't forget to re-export the model as a .stl file)

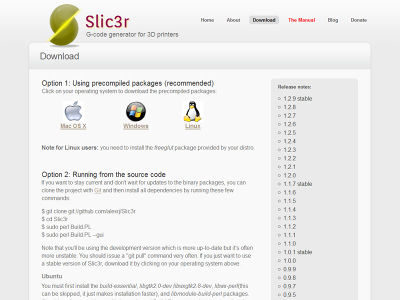

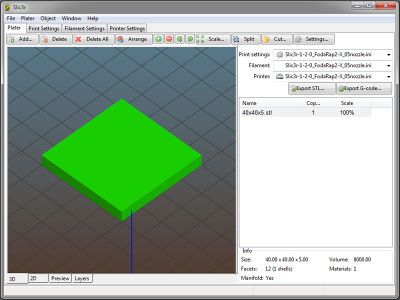

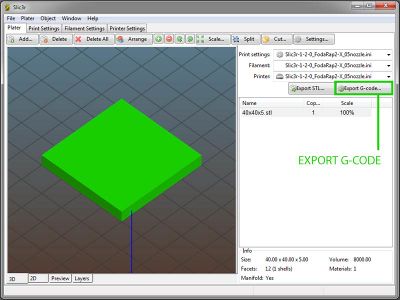

Slic3r

Define the printing parameters of your model in Slic3r

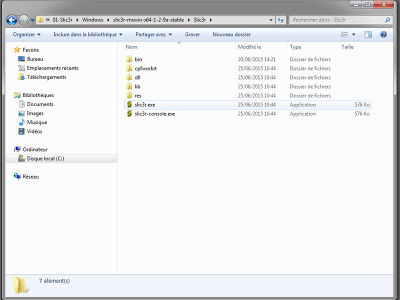

extract the files and execute slic3r.exe

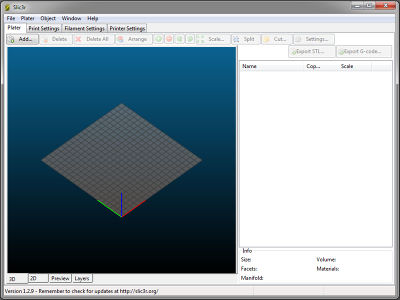

the Slic3r window opens without any installation

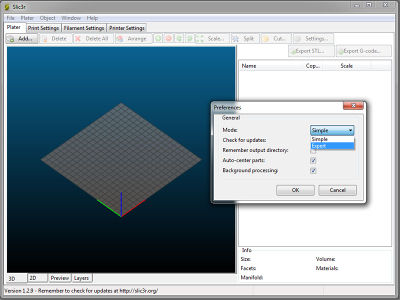

change the user mode: File > Preferences > Mode > Expert (then stop and restart Slic3r to integrate the changes)

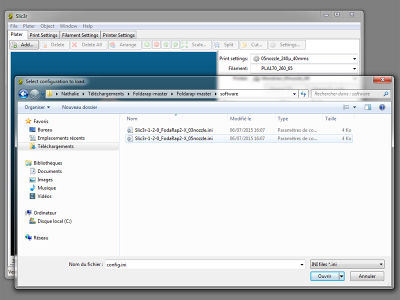

load the config adapted for the FoldaRap (from the FoldaRap-master file from GitHub): File > Load Config... > FoldaRap-master > software > config.ini (choose "05nozzle" if the nozzle diameter is of 0.5mm)

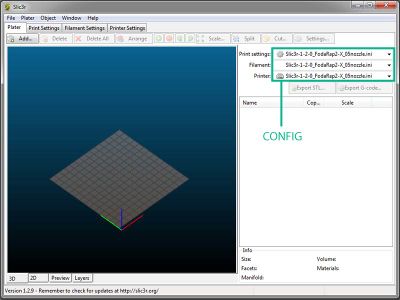

check if the configuration is well downloaded

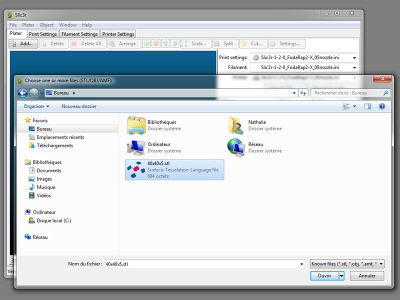

open the .stl file in Slic3r: Add... > File.stl

export the G-code containing every settings about: Print / Filament / Printer

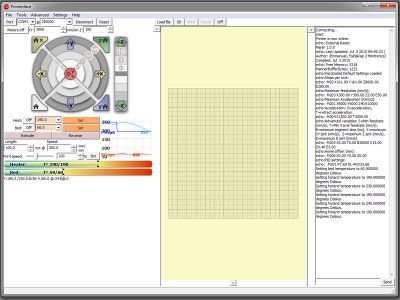

Pronterface

Drive your 3D-printer with Pronterface

the window Pronterface is probably still open and your printer still connected... if no: start again Pronterface and connect the machine on the correct port COM number @ 115200 baudrate

set the bed temperature to 65°C...

... and the hotend temperature to 195°C

once the hotend temperature is reached load the filament in the machine

pass the filament through a cube of foam (if you have one...): it acts like a filter and protects the nozzle against dust

position the spool on the spool holder

pass the filament through the extruder...

... between the pulley and the bearing...

... then push manually until you see the melted plastic passing through the nozzle (use the brucelle pliers to remove the melted plastic)

load the G-code on Pronterface...

... and print: the hotend and the bed will search automaticcaly the "0" position before starting to print

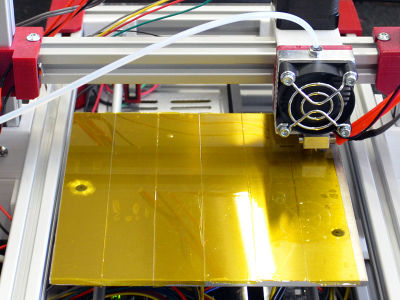

check the printing quality: if the nozzle is too high over the bed the filament won't stick on the Kapton (the filament draws small "waves")

if the nozzle is too low the filament looks thick or even doesn't extrude

if you notice one situation or the other adjust the bed level with the bed adjusters until the filament looks like on the picture

when your test parallelepipoid is finished wait the bed temperature to reach 40°C before removing the object (otherwise you can distort it)

check the object dimensions precision with a calliper (+/- 0.05mm)...

... and the object angles precision with a ruler and a set square (if the precision is not satisfying you might have to adjust the geometry of your machine: parallelism and perpendicularity of the aluminium profiles and/or smooth rods and/or lasercut parts)

Upkeep

The FoldaRap doesn't need much upkeep. Anyway it's important to look carefully at the following points:

- Make sure that your printing surface is always clean: if you put finger mark or grease / oil on your bed use a dry and clean duster to clean the bed while it is cold.

- Put some oil on the X and Z aluminium extrusion profiles (once a month).

- If you notice that the extrusion width decreases compared with your first prints then your nozzle is probably clogged. Please, see Unclog and follow the procedure.

- If the problem persists, heat the nozzle around 260°C (not more) and push by hand the filament through the nozzle: the blockage should go out of the nozzle and it will become easier to extrude the melted plastic.

- If not, you will have to disassemble the nozzle from the rest of the extrusion head, put it on an electric hotplate and heat it around 300°C for 1 hour (the blockage should sublimate).

Your FoldaRap is now ready. Have a lot of fun with your projects !

x1 foot front left

x1 foot front left

x1 foot front right

x1 foot front right

x2 200mm profile

x2 200mm profile

x4 M4x8

x4 M4x8

x4 T-nut

x4 T-nut

x1 foot rear right

x1 foot rear right

x1 foot rear left

x1 foot rear left

x2 200mm profile

x2 200mm profile

x4 M4x8

x4 M4x8

x4 T-nut

x4 T-nut

x1 hinge inner left

x1 hinge inner left

x1 hinge inner right

x1 hinge inner right

x4 300mm profile

x4 300mm profile

x10 M4x8

x10 M4x8

x10 T-nut

x10 T-nut

x1 y-idler

x1 y-idler

x1 M4x8

x1 M4x8

x1 T-nut

x1 T-nut

x1 M3x20

x1 M3x20

x1 M3 washer

x1 M3 washer

x2 603zz bearing

x2 603zz bearing

x1 M3 nut

x1 M3 nut

x1 y-motor

x1 y-motor

x1 M4x8

x1 M4x8

x1 T-nut

x1 T-nut

x1 nema 14

x1 nema 14

x2 M3x8

x2 M3x8

x1 pulley

x1 pulley

![]() x2 grub screw

x2 grub screw

x1 4,8mm ferrule (+ insulation)

x1 4,8mm ferrule (+ insulation)

x1 6,35mm ferrule (+ insulation)

x1 6,35mm ferrule (+ insulation)

x1 4,8mm ferrule (+ insulation)

x1 4,8mm ferrule (+ insulation)

x1 6,35mm ferrule (+ insulation)

x1 6,35mm ferrule (+ insulation)

x1 4,8mm ferrule (+ insulation)

x1 4,8mm ferrule (+ insulation)

x1 4,8mm ferrule (+ insulation)

x1 4,8mm ferrule (+ insulation)

x1 6,35mm ferrule (+ insulation)

x1 6,35mm ferrule (+ insulation)

x1 plug-plate

x1 plug-plate

x1 plug

x1 plug

x1 switch

x1 switch

x2 M3x8

x2 M3x8

x2 M3 nut

x2 M3 nut

x1 underplate

x1 underplate

x1 power supply

x1 power supply

x2 M3x8

x2 M3x8

x2 M3 nut

x2 M3 nut

x1 z-motor left

x1 z-motor left

x1 z-motor right

x1 z-motor right

x2 300mm profile

x2 300mm profile

x2 M4x8

x2 M4x8

x2 T-nut

x2 T-nut

x1 hinge outer left

x1 hinge outer left

x1 hinge outer right

x1 hinge outer right

x2 M4x8

x2 M4x8

x2 T-nut

x2 T-nut

x1 Z-slider left

x1 Z-slider left

x1 Z-slider right

x1 Z-slider right

x1 M3x30 countersunk

x1 M3x30 countersunk

x1 x-carriage

x1 x-carriage

x1 200mm profile

x1 200mm profile

![]() x6 grub screw

x6 grub screw

x1 nema 14

x1 nema 14

x1 pulley

x1 pulley

![]() x2 grub screw

x2 grub screw

x4 M3x30 (countersunk)

x4 M3x30 (countersunk)

x2 603zz bearing

x2 603zz bearing

x1 250mm belt

x1 250mm belt

x2 x-belt end

x2 x-belt end

x2 M4x8

x2 M4x8

x2 T-nut

x2 T-nut

x1 heater block

x1 heater block

x1 nozzle

x1 nozzle

x1 barrel

x1 barrel

x1 heatsink

x1 heatsink

x1 pneumatic fitting

x1 pneumatic fitting

x1 PTFE tube (2-4 mm)

x1 PTFE tube (2-4 mm)

![]() x1 grub screw

x1 grub screw

x1 thermistor

x1 thermistor

x2 female ferrule 2.54 mm

x2 female ferrule 2.54 mm

x1 2-pin casing

x1 2-pin casing

x1 cartridge heater

x1 cartridge heater

![]() x1 grub screw

x1 grub screw

x2 cable terminal (1.5 mm)

x2 cable terminal (1.5 mm)

x1 fan

x1 fan

x2 ferrule (1mm)

x2 ferrule (1mm)

x2 heatshrink sleeve

x2 heatshrink sleeve

x1 z-top left

x1 z-top left

x1 z-top right

x1 z-top right

x1 200mm profile

x1 200mm profile

x2 M4x8

x2 M4x8

x2 T-nut

x2 T-nut

x1 flexible coupling

x1 flexible coupling

x2 nylon nut

x2 nylon nut

x1 threaded rod

x1 threaded rod

x3 M3x30 countersunk

x3 M3x30 countersunk

x3 M3 nut

x3 M3 nut

![]() x3 spring

x3 spring

x1 y-carriage

x1 y-carriage

x3 linear bearing

x3 linear bearing

x4 zip-tie

x4 zip-tie

x2 female ferrule (2.54mm)

x2 female ferrule (2.54mm)

x1 2-pin casing

x1 2-pin casing

x1 endstop

x1 endstop

x2 heatshrink sleeve

x2 heatshrink sleeve

x2 ferrule

x2 ferrule

x1 endstop

x1 endstop

x2 heatshrink sleeve

x2 heatshrink sleeve

x2 ferrule

x2 ferrule

x1 y-endstop holder

x1 y-endstop holder

x1 endstop

x1 endstop

x2 heatshrink sleeve

x2 heatshrink sleeve

x2 ferrule

x2 ferrule

x1 blower

x1 blower

x2 ferrule

x2 ferrule

x2 heatshrink sleeve

x2 heatshrink sleeve

x2 cable terminal (1mm)

x2 cable terminal (1mm)

x1 extruder 1

x1 extruder 1

x1 extrudeur 2

x1 extrudeur 2

x1 extrudeur 3

x1 extrudeur 3

x1 M3x10

x1 M3x10

x1 603zz bearing

x1 603zz bearing

x1 nema 17

x1 nema 17

x1 insert (+ grub screw)

x1 insert (+ grub screw)

x1 hinge block left

x1 hinge block left

x1 hinge block right

x1 hinge block right

x2 M4x8

x2 M4x8

x2 T-nut

x2 T-nut

x1 spool-holder

x1 spool-holder

x1 M4x8

x1 M4x8

x1 T-nut

x1 T-nut