Choosing Belts and Pulleys

Contents

Choosing Belts and Pulleys

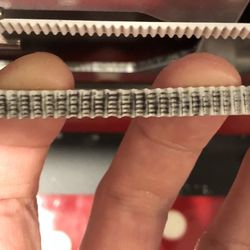

Timing belts

Traditionally RepRaps have been assembled using printed pulleys and T5 or XL belts. From an ideological standpoint, that makes sense, we should minimize the vitamin count wherever possible. Unfortunately, with the exception of the hot end and extruder, the pulleys and belts are probably the single most important parts when it comes to improving your print quality [citation needed], and the commonly used parts are almost completely wrong for what we do.

What's wrong with timing belts -- the status quo?

There are a number of problems.

Depending on how well tuned your printer is, the quality of your printed pulleys will range from good to atrocious. Even the best quality pulleys will not be up to the quality of commercial pulleys.

More importantly, the type of belts we use are all wrong. The T in T2.5 and T5 stands for Timing. It is designed to synchronize rotating shafts. It is not designed for linear motion, so it does not account for backlash in a reversing pulley. XL is also designed as a timing belt, but is a SAE standard, not metric. __The two are not compatible!__ If you have XL belts and pulleys that were printed for T5 belts, they may seem to fit but you will never be able to get decent prints.

Actually there are doubts about claim that T5 / T2.5 is causing backlash. (It is worth noting that despite nophead's stated doubts about GT2 vs T5/T2.5, in June 2015 nophead updated the Mendel90 github to utilize GT2 belts and pulleys by default).

How do we fix the problem?

To get the best print quality, we want to use a pulley and belt that are designed for linear motion. The GT2 series of belts are designed specifically for that purpose. They use a rounded tooth profile that guarantees that the belt tooth fits smoothly and accurately in the pulley groove, so when you reverse the pulley direction, there is no room for the belt to move in the groove. You should see an almost immediate increase in print consistency, especially around small holes and details.

How do I choose a pulley and a belt?

Generally speaking, for best performance you want at least 6 teeth in contact with the pulley at any given time. That minimizes the chance of the belt slipping, and helps reduce backlash even further. In practice that means you want a minimum of a 12 tooth pulley, and I usually try to get at least 18 teeth.

Beyond that minimum, fewer teeth are generally better than more teeth, since a smaller pulley gives both more torque and more resolution. You get more torque because the longer your "arm", the less torque you have (Imagine the load is mounted on an arm the length of the radius of the pulley, the shorter that arm, the easier it is to lift the load), and you get higher resolution, since you have a fixed number of steps per revolution, and a smaller pulley moves a shorter linear distance per step.

I recommend GT2, 2mm pitch, but you can also use GT3 3mm pitch. A finer pitch is preferable for the type of movement we do, and the belts are cheaper, but if you find the 2mm belts or pulleys are out of stock, you can go to 3mm pitch without any significant downsides. If you do choose 3mm pitch pulleys, be sure to get 3mm pitch belts as well.

Belt Materials

The most commonly found belts for 3D printers are made of rubber with some advertising that they are re-inforced with fibre glass. Rubber belts have very good flexibility but do stretch overtime with use. As well as rubber belts, Steel core polyurethane belts are also available. The steel core strengthens the belts against stretching over time however they also reduce the flexibility of the belt and have been known to break when used with pulleys of a small diameter allowing the belt to stretch significantly where the steel fibres have broken.

Since many 3D printers use 20 tooth pulleys or smaller, good quality reinforced rubber belts are recommended.

Where do I get them?

There are several sources for kinds of timing belts and timing pulleys. See the Belts and Pulleys and GT2 Timing Belt page for Belt and Pulley.